Forced air circulation can increase the efficiency of the heat exchanger and with this, it is possible to use a special compact heat exchanger, which would not function with natural convection alone. In addition, the temperature distribution in the device can be adjusted by targeted distribution of cold air, creating the perfect storage conditions in terms of temperature and humidity. The forced air circulation inside the device also prevents air moisture from condensing on the equipment parts and stored items.

Best possible level of device efficiency at minimum power consumption

To achieve the best possible level of device efficiency and therefore to minimise power consumption, every component must be optimised and particular attention must be paid to how the individual components interact with one another. In fans that are located inside the device to be cooled, energy is not just used to drive the fan; the motor heat generated by the fan must also be included in the overall thermal balance. The third crucial design parameter for household appliances is the noise emission. This must be kept as low as possible, as noise is an important quality factor.

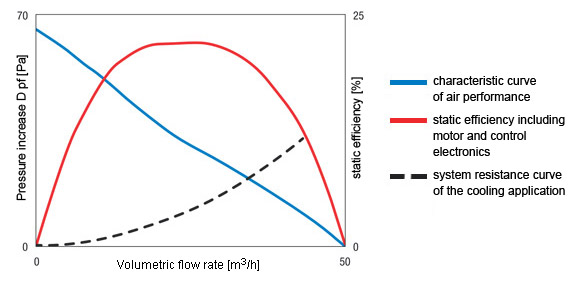

Design specifications for the fan can be derived from these basic conditions. In the instance described, the requirements led to a new centrifugal compact fan being developed, which, with an input capacity of around one watt, achieves a maximum efficiency of 22 %. The aerodynamic components have been especially designed and perfected for their application. The impeller and worm gear unit have been designed in unison so that an ideal interaction between the individual components can be guaranteed as early as the design phase.

A low circumferential speed for the impeller was very important in this process, as it results in low noise emissions. in line with the aerodynamic and aeroacoustic configuration, a motor that produced particularly low levels of structure-borne noise has been designed and adapted to the required speed and torque.

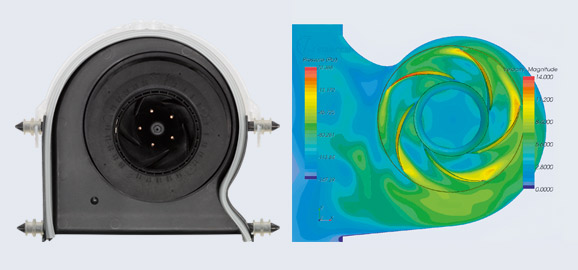

Figure 1: Completed fan and CDF model. The direction of rotation in the model is the opposite of the completed fan and the minimum distance between the impeller and housing has been increased in favour of noise emissions. There are pockets at the fan inlet for balancing weights, which are used to guarantee that the fan runs with low vibrations.

The aerodynamic components have been entirely designed with modern, three-dimensional computational fluid dynamics (CFD). These were used in the refrigeration unit in a much earlier state of development when defining the requirements for the fan. in the course of the development, the reaction of the fan to the noise behaviour was also evaluated by means of simulations. for this, the incompressible Navier stokes equations involving friction are solved for the given fan geometry. The geometry, i.e. the design of the blades, current cross-section and housing geometry, are modified until the current moves through the fan with as little noise as possible and with as little loss as possible. More details of the design process and the description of the experimental devices used can be found in Schmitz, et. al., Design and Test of a small High-Performance Diagonal fan, Proc. iGTi 2011, Vancouver.

Rapid-Prototyping

In the next state of development, the components of the fan are built in a rapid prototyping procedure, the motor is integrated and the entire unit is evaluated with regard to air performance and acoustics. The operating point of the fan is within the range 30-40 m3/h. In this range, the pressure build-up in the fan corresponds to the system resistance of 15-25 Pa. The fan achieves an overall efficiency of around 20 %. This means that one fifth of the electrical energy is converted into current energy. for a fan of this size and performance level, this is a very good figure, particularly when one considers the compromises that have to be made.

To achieve a higher level of efficiency, the gap between the rotating and static components must be kept as small as possible. However, if the gap is too small, there is a danger of the refrigerating unit freezing, which is why a minimum gap size must be adhered to. The smaller the distance between the casing tab and the impeller, the more audible the aeroacoustic interactions of both components. These contradictory requirements mean that compromises have to be made and the compromises needed for good acoustics were determined in experiments using prototypes.

Leave a comment