As an environmentally friendly heat source, gas has multiple advantages. In conjunction with modern gas condensing boilers, the fuel is optimally converted into useful heat. Gas condensing boilers can be made very small, are long-lasting and very quiet. For practically every application, therefore, you can find optimally adapted heating units on the market. In order to build these devices as compactly as possible and still do justice to the extensive variance, there is now a new, highly compact unit consisting of a fan, venturi and gas valve. It covers the large power range from 2 to 35 kW and can be easily adapted to different installation conditions in the gas condensing boiler. That saves time and money in design engineering and stock-keeping.

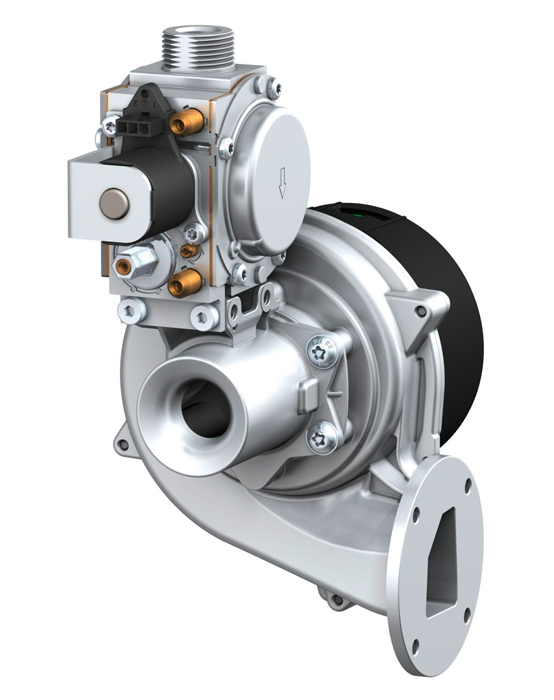

State-of-the-art gas condensing boilers are available in a large number of variants. The heart of such a device, however, is always the fuel management system, in other words, the optimum dosing and treatment of the constant fuel-air mixture. With the NRV 77, ebm-papst Landshut, the specialist for state-of-the-art condensing boiler system technology is now offering a new system for this, which allows for versatile adaptation to the different output and installation requirements. The objective of the innovation was to cover a large power range with the smallest, most compact dimensions possible, and simultaneously be able to vary the arrangement of the components when integrating them into the gas condensing boiler. Furthermore, the NRV 77 takes into account the development of heat outputs which are becoming ever smaller.

The whole is more than the sum of its individual parts

The fuel management system is composed of multiple single components. Along with the fan for the combustion air and the gas valve, the newly developed venturi is the component that is the key to success. All three components have to be optimally matched to each other for the respectively required heat output. This is the only way to guarantee efficient, low-emission combustion.

The fan: always the correct air flow

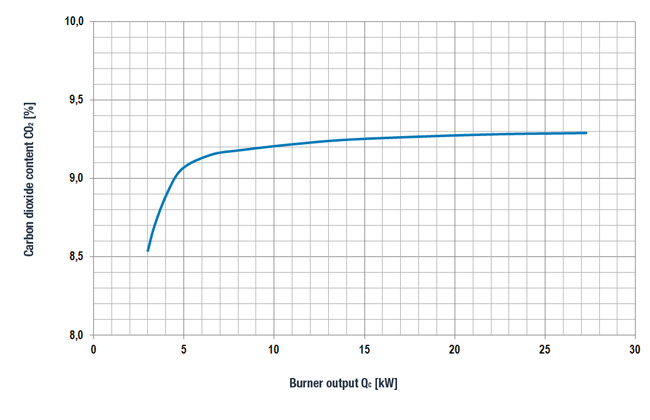

For conveying fresh air, this means that the fan used can always reliably move the air flow required for heat outputs from 2 to 35 kW. The reason for this is that a fan with a relatively small impeller diameter is used. This enables low air flows to be achieved with minimum speeds that can still be controlled well. To be able to cover the upper power range as well, speeds of up to 11,500 rpm are required.

However, the high speed and the long service life desired for use in heating require a special bearing design. Therefore the bearing geometry and above all the lubrication have to be adapted to these conditions. Carefully selected greases with ideal viscosity, temperature behaviour and ageing stability are the decisive factor here. Intricate (long-term) test bench trials in conjunction with long-time experience helped in the search for the optimum lubricant for a speed-proof bearing with lifetime lubrication.

The gas valve: large modulation range

For the smallest heat outputs the required fuel gas quantities are downright minuscule. NRV systems have a modulation range from 1 to 7, over which the air-fuel ratio of the combustion has to be controlled. What is called the main injection throttle of the gas valve is an important element here. It consists of a rotating plastic part, which is fastened in place on a sheet. The parts have to be as flush as possible with one another to ensure that the entire gas quantity is fed through the main injection throttle and no leaks past the throttle can develop. A leak would have a negative impact on the minimum heat output. Moreover, the choke (plastic part) has to move easily, so that the air-fuel ratio of the combustion is configured at the rated load.

The objective here was to find the best possible compromise, which was achieved by tempering the installed plastic part in the sheet metal and by optimising the sheet metal part. Thus it was possible to achieve the goal of creating a largely leakproof main injection throttle that can be moved ideally.

The venturi mixer

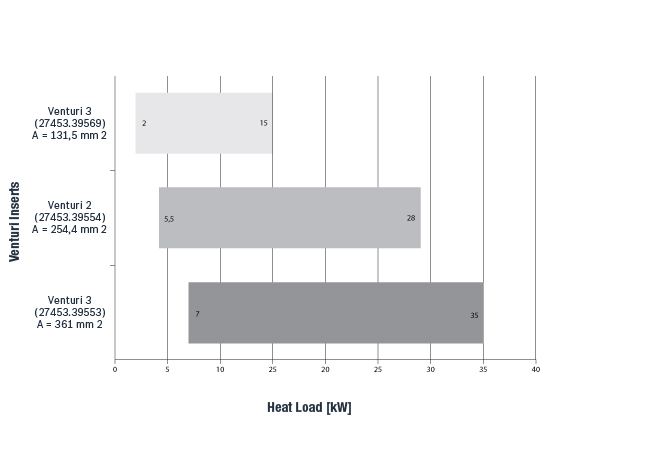

Venturi nozzles are frequently used to generate the required vacuum, through which the correct gas quantity is dispensed through the gas valve. A single venturi is not able to cover the entire power range of the fan and gas valve. But each new venturi nozzle means a new mold.

In order to find a flexible and cost-effective solution for our customers, we created a venturi with an integrated displacement body. Its diameter can easily be adapted in the overall tool by using an insert, but this does not have any negative impact on the venturi´s performance. Additionally, the entire venturi can be flexibly attached to the fan with various mounting options. We call this patented solution “multi-venturi”.

Technology in numbers

Thanks to the multi-venturi solution, system solutions (gas-air mixture) can also be cost-effectively provided in new tools in customer-specific, small annual production volume without investment costs. The product launch of the NRV 77 includes three performance classes, which cover the power range from 2 to 35 kW. Additionally, depending on the installation conditions, the gas valve can be turned in up to 15 different positions. A liquid seal is inserted between the multi-venturi and fan housing. This sealing point is 100 % tested in the plant.

Due to its wide output-control range, the new NRV 77 gas-air mixture permits use in a wide variety of different gas condensing boilers. Stock-keeping is reduced as a result of the large output variability; the design can rely on uniform standard components as a result of the flexibility. This not only saves money and time in development and production, but also improves the market opportunities by providing better quality at a favourable price.

Leave a comment