When it comes to a carbon-neutral future, most people talk about solar energy or wind energy. But there is another sector here that uses a lot of energy and has a negative impact on the global carbon footprint: heating. In Germany alone, this item accounts for more than 25 percent of total energy consumption; in private households, the share is even 90 percent. In addition, around 12 million heating systems are older than ten years in this country alone, and these therefore often have an unsatisfactory energy footprint. From a global perspective, the need to catch up is most likely even greater. In other words, if the energy revolution is to succeed, we need a heating revolution. The now well established energy-efficient gas-condensing technology, which has been continuously developed and refined over the past 20 years, makes an important contribution to this.

Combustion is crucial to the efficiency of these condensing units. The energy yield is only perfect with an optimum mixture ratio of air and gas. An excessive proportion of gas leads to harmful emissions such as soot and carbon monoxide, for example, and too much air reduces the efficiency of the combustion. It is therefore crucial that the components of the gas-air composite system are perfectly matched. In this regard, pneumatic combustion control has proven itself in practice for years. As a future-proof alternative, the electronic combustion control system is added to this. In the long term, it may even replace its pneumatic sister. Until then, however, both systems will run in parallel on the market. ebm-papst offers both variants as a complete solution for use in condensing units in residential buildings up to 150 kW: CleanEco (pneumatic) and CleanVario (electronic).

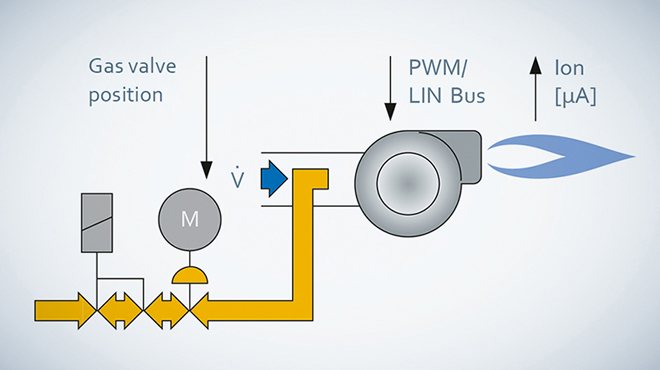

Figure 1: Functional diagram of CleanEco pneumatic combustion control. (Graphic | ebm-papst)

CleanEco: robust and tried-and-tested

The CleanEco pneumatic composite system consists of a blower, venturi, gas valve, and the control unit (boiler control unit – BCU (Fig. 1). The principle: The blower draws in the air, a vacuum is created by the tapering of the venturi, which controls the gas supply via the valve. When correctly adjusted, this results in the optimum mixture of oxygen and fuel. The gas-air mixture remains stable regardless of counterpressure and changed exhaust gas resistance. Over the years, the engineers at ebm-papst have optimized the system so that modulation levels of 1:10 are now possible, meaning the output of the boiler adapts much more precisely to the demand actually required. But even though the pneumatic composite system is tried and tested and robust, it depends on a constant gas quality, as the valve is precisely set to the relevant type of gas fed in at the site of the installation.

CleanVario: a flexible system

Figure 2: CleanVario electronic combustion control. (Graphic | ebm-papst)

And it is precisely here that a major change is happening. Looking at Europe makes this clear. Large gas fields, such as in the Netherlands, are almost depleted and new sources need to be found. This also includes alternative fuels. In addition to natural gas, in future hydrogen, liquid gas, or biomethane from power-to-gas plants will also flow through the pipes. This means that the condensing units of the future will have to react flexibly and have to deliver constant performance despite these fluctuations. A system is therefore required that is gas adaptive. The answer to this challenge already exists: the electronic gas-air composite system which goes by the name CleanVario at ebm-papst (Fig. 2).

When looking at the components, there is initially no major difference. There is still a blower, venturi, control unit, and gas valve here, but their interaction is different (Fig. 3). The mixing ratio is not controlled here by the vacuum but by electronic actuation of the gas valve. The gas valves in CleanVario therefore have a stepper motor which is used to regulate the feed precisely. But to ensure that the valve knows how much gas it is to provide for mixing with the air, it requires a parameter that signals when the mixture is perfect. In theory, the ideal mixture of fuel and air for complete combustion is a combustion ratio of λ = 1. If the value is below one, the oxygen content is too low; if it is greater, then it is too high. But how do you measure whether the combustion is running optimally? The best way is the flame itself.

Figure 3: Functional diagram of CleanVario electronic combustion. (Graphic | ebm-papst)

The flame is crucial

For CleanVario, ebm-papst relies on so-called ionization technology. This utilizes the fact that the flame is electrically conductive. If a voltage is applied, an electrode can measure the so-called ionization current directly on the flame. This can be used to draw conclusions about the combustion quality. If the current is too weak, the valve receives the signal to supply more gas; if it is too high, it restricts it (see gallery below).

This enables the combustion to be controlled independently of the fuel. The system can thus automatically adjust to the gas type without any changes to the valve, and provide clean combustion. This now also works if up to 30 percent hydrogen is added. However, the major challenge here is to measure the ionization current precisely, as it is in the microampere range. The developers at ebm-papst have therefore put a lot of expertise into the flame amplifier, which, as its name suggests, strengthens the signals received by the sensor. It is important that interference signals, such as mains hum, are filtered out in the process.

Intelligence for the future

But without intelligent software, the data obtained would be worthless. For both pneumatic and electronic complete systems from ebm-papst, the intelligence is located in the boiler control unit (BCU), the central control unit. It regulates all electronic safety and control functions of condensing boilers.

Complete system from a single source

With both CleanEco and CleanVario, manufacturers get a perfectly coordinated complete system consisting of a boiler control unit (BCU), gas valves, venturis, and gas blowers. ebm-papst covers four performance classes with its product range: 2 – 35 kW, 4.5 – 50 kW, 9 – 80 kW and 15 – 150 kW.

In the case of the CleanVario electronic system, it can collect and evaluate the data obtained from continuous combustion monitoring in order to ultimately optimize the unit‘s operation in the sense of a self-learning system, in the spirit of GreenIntelligence. During the next start, for example, the stored switch-off states can be used to quickly reach optimum start conditions. The electronic composite system also offers a major advantage in terms of predictive maintenance, as a lot more information about operation is available. For example, an increasingly small flame signal indicates that the electrode on the flame has to be replaced.

Everyone benefits

With CleanVario, manufacturers have the greatest possible flexibility. When it comes to boiler design, there is more leeway for developers because the valve can be installed in the unit regardless of position. Since the units are gas adaptive, this is not just an advantage with regard to fluctuating gas characteristics. Serving global markets is also much easier, as the gas valve no longer needs to be adapted to the specific conditions of the respective country. It is also much easier for installers because they simply have to install the unit without any time-consuming configuration. The end customer ultimately has a unit that provides clean and reliable combustion over its entire service life. That just leaves the environment. If modern gas condensing units are used extensively, the chances are good that we can meet the set climate objectives, too. CleanEco and CleanVario can help with this.

The best of both worlds

Advantages with CleanEco

- Tried-and-tested and robust system for years

- Stable gas-air mixture regardless of back pressure and changed exhaust gas resistance

- High modulation up to 1:10

- Fast power modulation

- Adjustable excess air values over the entire modulation range

- Monitoring of hygienic combustion by flame signal monitoring

Advantages with CleanVario

- Clean combustion over the entire service life

- Reliable start and operation of the burner

- Flexible gas-air ratio in terms of time and over the entire modulation range

- Automatic gas family detection and adaptation to installation conditions

- Simple installation

- Suitable for all known combustion gases and admixtures of up to 30 percent hydrogen

- Continuous combustion monitoring enables improved diagnostics and predictive maintenance

- Greater flexibility in boiler design

Leave a comment