The material heat is made of: Biomass heating systems – using wood chips for example – are enjoying double-figure growth rates

To start with, Dr Johann Gruber was somewhat sceptical when Thorsten Hartl, sales manager at ebm-papst Austria, suggested using an EC induced draft fan for a new wood chip heating system instead of an AC model. “We had actually been considering a larger impeller to achieve a greater air performance,” recalls the head of development at Hargassner. The company manufacturing wood chip, pellet and wood burning systems based in Weng im Innkreis in Upper Austria is one of the leading European specialists in the field of biomass heating technology – a market enjoying double-figure growth rates. Hartl’s suggestion was however very much in keeping with the ideas of Gruber and Anton Hargassner, the junior director of the company: They were looking for a way of enhancing the efficiency of the wood chip heating method which would keep emissions to a minimum whilst consuming less power than earlier models and at the same time permitting a compact design.

After initial discussions with Hargassner, Hartl soon realised: Only an EC motor is capable of satisfying such requirements. Despite some initial scepticism the decision was therefore taken to try out EC technology for the first time in the biomass branch. “It came as quite a surprise to discover that we reached the air performance target with room to spare in spite of the smaller impeller.” This was however only possible on account of super-synchronous speeds above 2,800 rpm.

Central control instrument

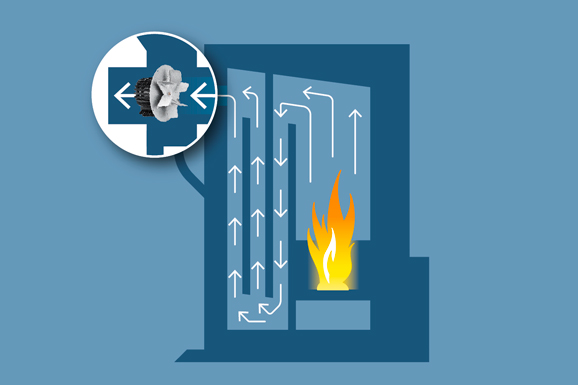

No mean feat, as the performance of a heating system is largely determined by the air throughput in the boiler. The induced draft fan plays a crucial role: It produces a vacuum in the combustion chamber and thus creates the mixture ratio required for optimum combustion. This ratio is measured with a Lambda probe – a sensor which controls the combustion air composition on the basis of the measured values. And the more finely the air throughput can be regulated, the better the output can be modulated. This is particularly important when burning wood.

Optimum combustion guaranteed: The induced draft fan produces a vacuum in the combustion chamber and so controls the mixture ratio

When compared to other forms of energy, the fuel to which Hargassner has been dedicated for 30 years almost always comes out on top: Whereas oil and gas prices are constantly on the increase and resources are dwindling, trees are regenerative and supply heating material at a cost which has remained steady for years at a level well below that of fossil fuels. What’s more, the sustainable raw material only gives off the amount of carbon dioxide on burning which it absorbed in the course of its growth and its climate effect is therefore neutral.

Legislation governing permissible emission levels is becoming ever more restrictive and accordingly a crucial aspect in development work. Emission values can only be reduced if the wood burns optimally, which in turn depends on the properties of the induced draft fan. This however requires electricity to operate. So the second major challenge was to keep the power consumption as low as possible – not least because induced draft fans run for up to 2,500 hours per year. “Consumers take a close look not just at the fuel but also at the electricity costs involved,” Hargassner stresses. Hartl is of the same opinion: “Power consumption is the benchmark on which today’s purchasing decisions are based.”

Economical, compact and powerful

EC technology from ebm-papst enables Hargassner to reduce the power consumption of the new heater by 50 per cent. “With this very low level we are now the best in our branch,” as Hargassner is pleased to point out. In addition, the DC motor permits infinitely variable speed control and thus ideal, low-emission combustion. “The test authorities told us that we are the only manufacturers with such low emission figures,” Gruber explains. “We can now achieve a far higher efficiency level, particularly in the low speed range.” A further advantage is that the flat impeller permits a compact design. “With an AC motor we would have had to use a larger model to achieve such performance and construct a giant induced draft unit to go with it.” Another aspect is ease of installation. “We have adapted the EC induced draft fan in such a way that Hargassner now only has to tighten four bolts and connect the power and control cables,” explains Hartl.

Successful cooperation

The new wood chip heating system has been on the market since March 2013 under the name ECO-HK and is intended primarily for customers in the agricultural and industrial sectors. The Austrian Ministry of the Environment and the Upper Austria region have already honoured the system with the “Energy genius 2013” innovation award. “The ECO part of the name is intended to emphasise the very best in terms of efficiency,” according to Gruber. “We don’t cut any corners when it comes to quality – and that’s what we like about ebm-papst.” The two companies have been working together to their mutual benefit since 2006. And the effort has been well worthwhile, as Gruber can confrm: “We do of course have yet more plans in the pipeline in connection with EC technology.”

Leave a comment