There is demand for efficient and, most importantly, quiet air/water heat pump systems suitable for indoor, outdoor or hybrid use, which use natural refrigerants and whose output can be intelligently adapted to the actual conditions. This requires fans that not only operate economically at optimum efficiency and pleasant noise levels, but can also communicate and be intelligently networked. As the noise and power consumption of the speed-controlled compressor drive also have to be factored in, there is an additional need for inverter electronics that reduce operating noise through optimum commutation and simultaneously improve the energy efficiency of the heat pump.

Heating with heat pumps

Today’s heating systems demand concepts based on renewable energies. ebm-papst delivers low-noise and efficient components.

Fans and inverter electronics for quiet operation

Motor and fan specialist ebm-papst supplies various types of efficient and acoustically optimized EC fans for air/water heat pumps. For particularly noise-sensitive outdoor areas, for example, there are two axial ranges that are especially suitable for use with natural and flammable refrigerants and are extremely quiet thanks to their special design (Fig. 1). This prevents the heat pumps from becoming a disruptive factor and allows them to blend in well with their surroundings. While the AxiEco plug-in is suitable for heat pumps requiring a large pressure reserve for the evaporator, the AxiTone is geared more towards delivering higher air flow at low back pressure when the heat pump design requires this.

Based on many years of experience with EC motors, their commutation electronics and heat pump applications, the company has also developed inverter electronics (Fig. 2) with an electrical output of up to 3.5 kW, 7.5 kW and 12 kW, respectively, which are suitable for speed-controlled permanent magnet synchronous motors (PSM) such as those that are often used in heat pump compressors. The commutation process has been optimized over a period of decades and significantly reduces noise levels. At the same time, it improves efficiency, thus increasing the COP (coefficient of performance) value of the terminal apparatus by several percentage points.

Design and testing

EMC compatibility was taken into account when developing both the inverter electronics and the energy-saving EC fans. For example, integrated three-phase active power factor correction (active PFC) ensures the optimal EMC properties of the inverter electronics and EC fans. No additional measures are required to comply with the standards with regard to current harmonics. Given that, depending on the size of the heat pump, conventional expansion valve assemblies can easily weigh up to 20 kg, considerable weight and space savings are achieved by using integrated active PFC. The wiring effort is also reduced.

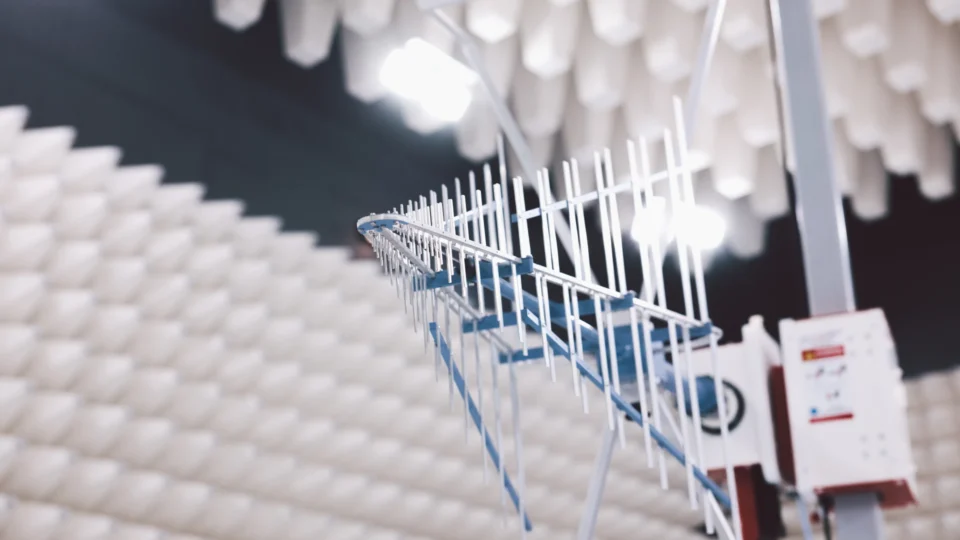

At ebm-papst, all EC fans and electronics are tested in accordance with the state of the art and using the considerable engineering expertise of the large EMC laboratory at the Mulfingen site, which has been in operation since 2021. It is possible to measure the response to both conducted interference in the cables and interference emissions, i.e. electromagnetic waves that travel through the air.

Large-scale EMC tests

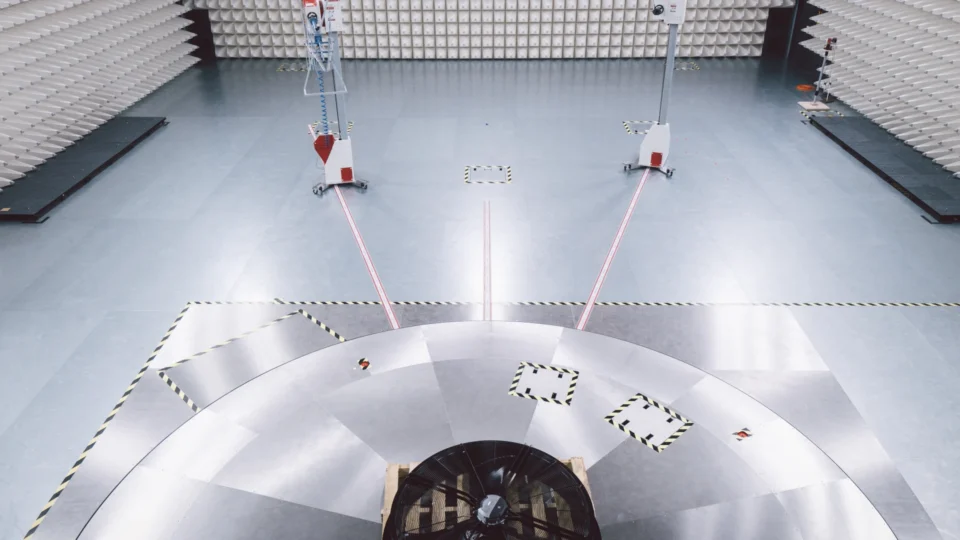

Spread over two floors, the EMC test laboratory covers a total area of 2,500 m². Much of this space houses the shielding and absorber rooms needed for the EMC measurement technology (Fig. 3), in which more than 100,000 ferrite tiles and over 4,000 pyramid-shaped absorbers are installed (Fig. 4). On the one hand, the rooms shield against external sources of interference; on the other hand, they facilitate the simulation of a free field environment. Here, the immunity to interference and interference emissions can be measured in compliance with the standards on test units up to 60 m³ in size and 20 t in weight.

These test units not only stem from the company’s own development activities, but also include entire customer systems such as heat pumps with propane as the refrigerant. After all, it is not only the components installed in the heat pump that must comply with the relevant EMC guidelines. The heat pump manufacturer must prove that, during operation, its entire system does not interfere with other electricity-consuming apparatus in the network and is also not subject to interference itself. Put simply, this means that starting the heat pump in the garden does not cause the television in the living room to flicker.

The manufacturers of heat pumps are familiar with the challenges that need to be addressed. For example, unfavorably routed cables often cause EMC problems. It therefore makes sense to check EMC compatibility before actual certification so that the time to market is not delayed unnecessarily. Multiple test cycles are often necessary and slots are difficult to come by in many test laboratories. For this reason, ebm-papst offers its customers the opportunity to test entire systems in its laboratory, serving as a development partner and providing access to its many years of heat pump experience (Fig. 5). EMC disturbance can then be detected and eliminated at an early stage (Fig. 6), enabling the heat pump to be brought to market more quickly.

Leave a comment