AGVs have been in use for a long time in many warehouses, distribution centers and manufacturing facilities. They are used to transport material in containers or on pallets, without requiring a physical transport network. Yet, if you look around many halls, the AGVs move in a rigid and inflexible way, running along the line markings made on the floor.

So long as rigid production lines are being set up, particularly in manufacturing, there is an elegant material supply solution using track-guided solutions. If the products to be manufactured go through the machines like a pearl chain, from one processing step to the next without variance, the flow of material does not require any changes.

Track-guided solutions have advantages, such as a low level of complexity and comparably simple safety technology, but their flexibility is very limited. The AGVs can only stop if they reach obstacles: they cannot drive around them. However, the far greater disadvantage in modern manufacturing scenarios is that selectively approaching production stations and implementing automatic route changes is not possible. Route changes require new line markings on the floor: it is not possible to simply reconfigure them using software.

This means that track-guided solutions in modern manufacturing and intralogistics concepts are no longer keeping pace with the times, because the increasing number of assemblies with a modular set-up for high product variance require new concepts to keep goods flowing. In addition to a flexible flow of materials, mobile machines are also an important factor. For example, AGVs automatically transport the robot mounted onto them to the next workstation.

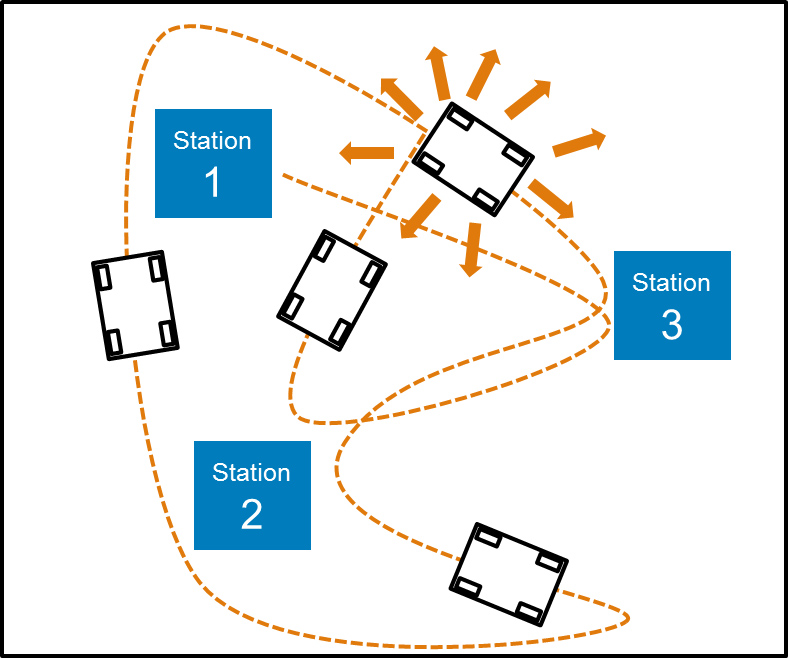

Modern production concepts require AGVs that can navigate completely freely and offer unrestricted free-range mobility. (Graphic | ebm-papst)

AGVs that can navigate completely freely and offer unrestricted free-range mobility are necessary for implementing modern manufacturing concepts and optimizing intralogistics processes. Of course, controlling and navigating vehicles with free-range mobility is more complex. There are greater requirements for sensors and safety technology, but sophisticated solutions already exist. Below, read why extensive free-range mobility with omnidirectional freedom of movement in AGVs enables greater efficiency in logistics and production.

Reduce space requirements and the associated costs

On the one hand, space in warehouses and manufacturing facilities comes at a high fixed cost. On the other hand, it soon becomes difficult to find space to carry out all of the necessary activities, particularly if there is a growing volume of orders. Therefore, making optimum use of space provides an important contribution to the Overall Equipment Effectiveness (OEE) in existing buildings and manufacturing areas as well as in new designs. For track-guided AGVs in particular, a lot of space has to be reserved for the routes.

Limited maneuverability means that a lot of surface area is required to accommodate the bends and load transfer points. In principle, these AGVs can be compared with passenger cars, as these too have a limited freedom of movement. For example, it is not possible for them to turn when stationary or to move sideways. In addition, the line-marked routes must always be kept clear, including a safety zone. It is not possible to place temporary structures or to store materials and machines there. Flexibility in the layout of logistics and manufacturing areas remains restricted.

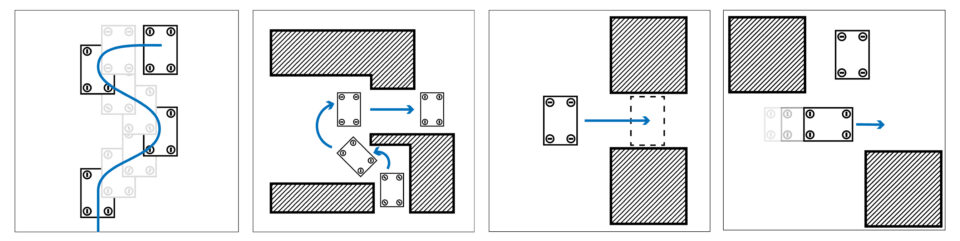

Even in very confined environments, the AGVs can carry out exact manoeuvres with omnidirectional motion.

However, using freely navigable AGVs with drive solutions for free-range travel means that a lot less space is required for cornering and maneuvering at material transfer points. Omnidirectional systems with complete free-range mobility enable all travel manoeuvres. These include moving transverse to the direction of travel, turning when stationary and many combinations of movements.

Even in very confined environments, the AGVs can carry out exact manoeuvres with omnidirectional motion. In principle, their maneuverability is comparable with a hovercraft: the orientation of the transport frame is independent from the direction and position of travel.

Enabling modular production

AGVs’ free-range mobility not only saves space. The free navigation also reduces the distances that need to be traveled and simplifies driving around sudden or temporary obstacles. This increases the dynamics and speed and, therefore, the material throughput. Furthermore, the AGVs’ free-range mobility makes it possible to implement future-oriented and modular productions for the first time.

A new drive solution for AGVs with free-range mobility: The ArgoDrive driving/steering system from ebm-papst. (Photo | ebm-papst)

Due to the smaller batch sizes and constantly increasing product variance, rigid conveyor belts and inflexible production lines are increasingly becoming a thing of the past. The future of production means flexible manufacturing down to a batch size of one. In this context, both machines and entire production lines have to be quickly converted using modularization. This also requires flexible material transport, both to the machine and to the next machine. Mobile robotics is also being increasingly implemented in modular manufacturing systems.

Application scenarios for extensive free-range mobility

These scenarios can no longer be achieved with track-guided AGVs. The vehicle solutions have to be moved freely to the next workstation via sensors, which is implemented using a higher-level localization and control system. This control system knows exactly when and where which processing station has to be approached by which AGV with which goods and assigns the appropriate travel orders.

Since the layout of the space in modern manufacturing scenarios changes often and every angle is utilized, the AGVs must be extremely maneuverable and offer omnidirectional mobility to reach their destination quickly and safely even in very tight environments. The AGV also has to guarantee quick and safe braking using its drive technology if there are unexpected obstacles. Driving on different floor coverings and overcoming gradients are other demands placed on the drive technology to allow greater flexibility in manufacturing and the associated intralogistics.

Since the layout of the space in modern manufacturing scenarios changes often, the AGVs must be extremely maneuverable and offer omnidirectional mobility.

Although the floors at manufacturing sites and logistics centers are typically made of smooth, cement-bonded industrial screed with an acrylate-based primer, halls often have strong expansion joints, rough sections and different coverings. In addition, AGVs also have to travel back and forth between halls, for example to get material from the warehouse.

When doing so, the AGV has to travel over tarred surfaces and often overcome inclines at crossovers. Drive solutions with high maneuverability, such as the Mecanum wheel, quickly run into problems here, because they require smooth ground to move. However, this restriction is not necessary, as there are driving/steering systems that meet all the requirements of future-proof AGVs.

Fine positioning for high precision

The omnidirectional mobility of AGVs, facilitated by modern driving/steering systems, is also required for fine positioning at the machine and at material transfer stations. Here, precise adjustment down to the millimeter is required to enable containers to be moved into the workstation, for example. Equipped with high-resolution sensors and low-backlash mechanics, an omnidirectional driving/steering system positions every AGV quickly and efficiently with maximum precision.

With the ArgoDrive driving/steering system from ebm-papst, AGVs navigate freely and omnidirectionally over the entire area, drive around unexpected obstacles and move easily even in very tight environments. (Graphik | ebm-papst)

However, the majority of current mobile AGVs have a chassis concept with three wheels, in which only one – like a classic forklift concept – ensures steering movement. Differential solutions are also widespread: in this chassis concept, the AGV can rotate around its own axis but does not perform transversal movements.

Precise positioning requires time-consuming repeated forward and backward movements with additional steering or rotational movements: this also requires additional space. Drive concepts for vehicles with omnidirectional motion, such as pivoted bogies or Mecanum, once again have special requirements for the floor condition, are slow and have a high level of complexity.

Efficient implementation of free-range mobility

A new drive solution for AGVs with free-range mobility is the ArgoDrive driving/steering system from ebm-papst. It combines propulsion and steering functions in one assembly. This unit consists of motors, special transmissions, sensors and all the necessary connections. Its two motors contribute towards steering, acceleration, movement and braking, depending on requirements. The infinite steering angle enables space-saving, free-range vehicle movement – even from a stationary position.

The driving/steering system from ebm-papst combines propulsion and steering functions in one assembly.

Two driving/steering systems on the left and right side of the AGV guarantee full omnidirectionality. Two additional freely moving support wheels on the front and rear ensure stability. Depending on the required size of AGV and the weight of the goods to be moved, three or four driving/steering systems can also be installed. This enables large loads to be achieved even if there are inclines.

ebm-papst offers its ArgoDrive driving/steering system in light, standard and heavy versions for weight classes up to 100, 300 or 500 kg in order to meet every requirement for moving masses, for braking and for mastering inclines in a scalable way. For example, four driving/steering systems in the heavy version allow a total vehicle weight of up to two metric tons.

Benefits combined in one driving/steering system

There are various chassis concepts for putting AGVs into service. How maneuverable the vehicle is in the end and how much load it can carry depends greatly on the drive and the wheels. Depending on topology, users often have to accept compromises and, for example, sacrifice maneuverability or compactness. New solutions such as the driving/steering system from ebm-papst minimize any compromises for manufacturers of future-oriented AGVs.

Leave a comment