The magic word is dynamic steering. This new steering uses the vehicle speed to change the steering ratio and simultaneously adapt the steering torque. At high speed an indirect ratio and higher steering torque improves the directional stability. The dynamic steering is extremely accurate with its smooth-running especially when parking — only two turns of the steering wheel are needed from stop to stop.

Stability and dynamics

The system utilises an interactive gearbox to supplement the power steering and the ESP. The gearbox absorbs manual impulses generated by the steering wheel as well as those from a high-dynamic EC motor. Drivers have a direct ratio at their disposal, they can control their vehicles with precision and react quickly: for example when parking, in city traffic or on winding roads in the low and medium speed ranges. The speed of the EC motor for moving the steering wheel is added in these situations, which means that drivers have to turn the steering wheel much less — a considerable increase in comfort and gain in agility.

In critical situations at high speed, such as when oversteering after sharp evasive action, the dynamic steering can prevent the rear from swerving. When understeering — pushing the car to the outer edge of the curve — the dynamic steering also intervenes helpfully: it becomes more indirect for a short time and assists drivers with using the area in which the tyres still have good adhesion to the road surface. The steering also becomes more indirect at high speeds in which the steering angle is reduced by the angle of rotation of the EC motor. The system checks several vehicle parameters so that the motor is operated in the correct direction — direct or indirect. The main parameters are the speed in addition to the steering angle. The dynamic steering works hand in hand with the ESP to provide stabilisation. The major advantage of this interplay lies in the fact that the ESP now acts on the dynamic steering rather than on the brakes according to situation. In an emergency the adaptive steering therefore quickly helps the vehicle to achieve a stable line — at the same speed. Drivers experience the stabilisation more harmoniously and more comfortably than without dynamic steering.

Quieter, smaller, more efficient

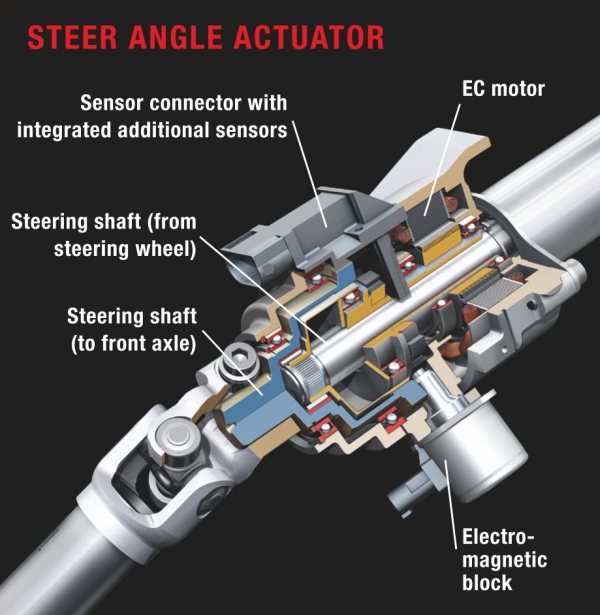

In the differential steering systems currently known on the market, which were also developed by ebm-papst together with ZF Lenksysteme GmbH, the electric motor had to be designed to cope with high environmental influences. Its unprotected installation location in the engine compartment, in close proximity to the front axle, subjected it to dusty heat, perishing cold or dampness as well as aggressive fluids: from screenwash through brake fluid right up to battery acid. On the A4, though, the drive sits in the column directly behind the steering wheel as an integral component of the steering column. In this design, the steering shaft is routed right through the electric motor and therefore provides several advantages at the same time: it is protected from climatic influences and can be installed universally as opposed to previous solutions dependant upon the space available in the engine compartment.

On the A4, though, the drive sits in the column directly behind the steering wheel as an integral component of the steering column. In this design, the steering shaft is routed right through the electric motor and therefore provides several advantages at the same time: it is protected from climatic influences and can be installed universally as opposed to previous solutions dependant upon the space available in the engine compartment.

The innovative trick opened up a whole series of new hurdles that the developers in St.?Georgen, at ZF Lenksysteme and Audi had to tackle. The requirements changed due to the fact that the motor was moved into the passenger compartment. Of course it no longer had to be sealed, but it now had to be quieter, smaller and more efficient. The basis for development was therefore offered by a new EC motor design with a high power density optimised for the installation space. The brushless electric motor stood out from the outset through its low noise level at top working speed. Furthermore, it lasts throughout an entire vehicle life — and its energy efficiency is unrivalled. This innovative technology allowed drive integration in the steering column. It would not have been possible to have realised this system and the enormous power density with conventional electric motor systems.

The requirements constantly increased during the development phase. According to Thomas Schrag, sales support manager at ebm-papst St. Georgen, the initial motor was completely different than the one finally used. “We had very little room available anyway, and because of the crash specifications the EC drive for the dynamic steering has now become very short — one millimetre less space and it would have had to be built very differently.” The solution worked out by the engineers can not only no longer be heard, it is also unnoticeable that a drive is working in the steering column. “The motor now has an absolute minimised detent torque, no torque ripple can be felt on the steering wheel, (torque fluctuations whilst the steering wheel is being turned and the electric motor is working). Our developers sat for months working on a solution to this problem”, recalls Schrag.

Despite the secret helper, the driver always has direct contact to the front wheels via the steering wheel, which is also a legal requirement. The driver always has full control, even in the unlikely event that the motor for the differential steering system should fail. The intelligent technology now puts every manoeuvre to the test wherever driver error was frequently the cause of accidents to date. This is how the system helps in achieving extra driving stability and comfort – and therefore greater joy at driving.

The heart of the power steering

The heart of the power steering

The mechanism of the dynamic steering system, the actuator, is integrated directly into the steering column. It consists of an EC motor with position sensors, an interactive gearbox and a lock to secure the motor into a motionless position. The Harmonic Drive gearbox ensures that both the manual pulses from the steering wheel and those from the EC motor are transmitted to the steering gear of the front axle. The interactive gearbox works almost clearance-free and with great efficiency. The motor itself, as a load-bearing element, is a component of the steering column, the steering axle passes axially through the motor.

the adaptive steering system is described in a very good manner

Interesting. I have a 2009 Audi A4 3.0TDI with the dynamic steering option and 252000km already on the clock. The harmonic drive system still appears to work otherwise fine, but there is a clear “electric motor”-type noise when the steering wheel is turned at lower speeds, especially in the parking lot. In motorway driving it is no longer noticeable. The noise comes from the steering column and is not present when the engine is shut off.

I haven’t seen anyone else mentioning this noise, and of course the official Audi repair directive would just be to replace the whole steering column if I wanted to fix it. But that wouldn’t be fun at all, especially as I’m thinking that it’s just lubricant that has dried up somewhere in the actuator. As an engineer, it would be intriguing to hear from someone who has worked on designing this system. What in the actuator should be relubricated (and with what?) and how to best access that part? ;)