Cleanrooms have particular requirements when it comes to their ventilation systems. These requirements include sufficient air throughput and pressure, precise control of temperature and humidity, as well as a constant air purity achieved by filtering out even the smallest impurities. Filter-fan-units (FFU) designed for ceiling installation combine filter technology and state-of-the-art fans, enabling them to meet these requirements to optimum effect.

2.330m³/h

delivered airflow

60%

achieved efficiency

6–7dB

lower noise level

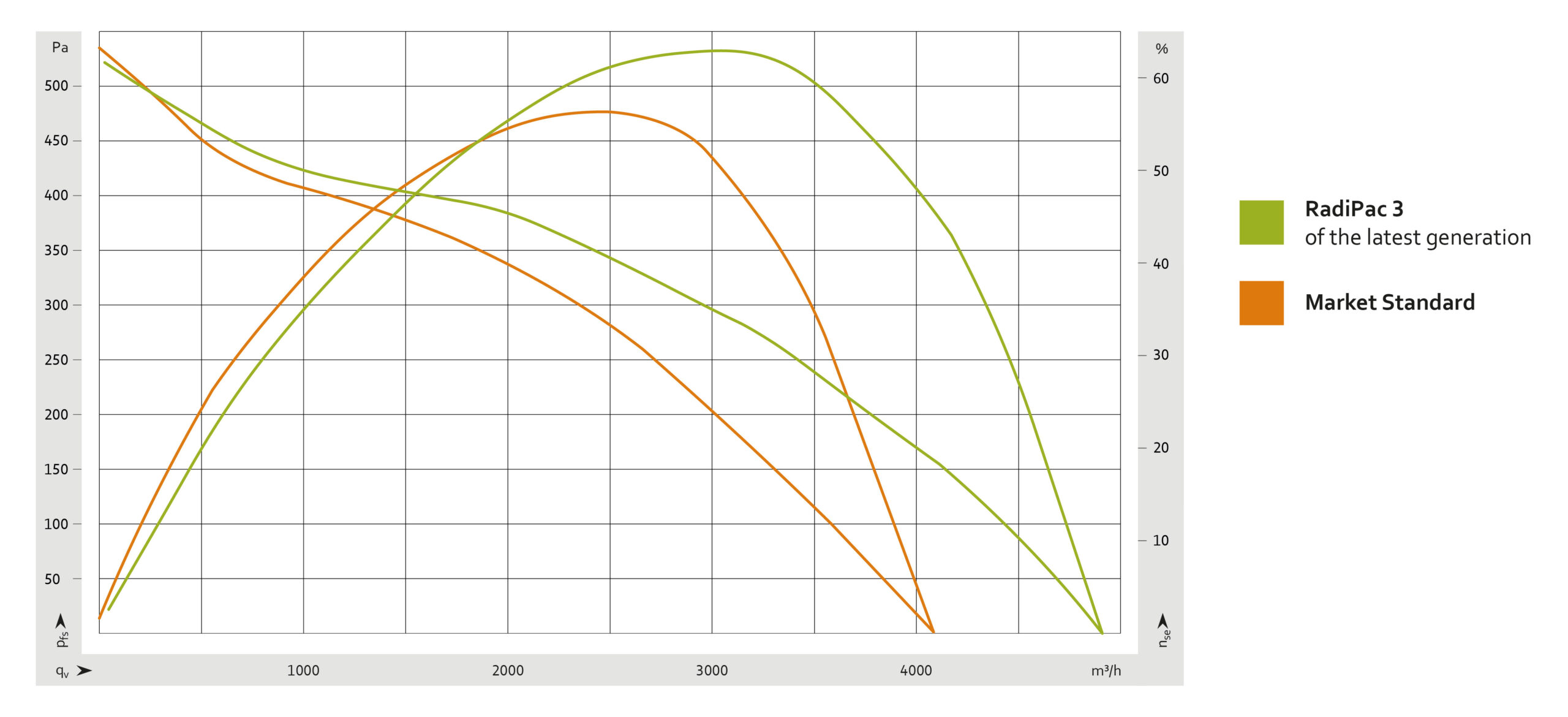

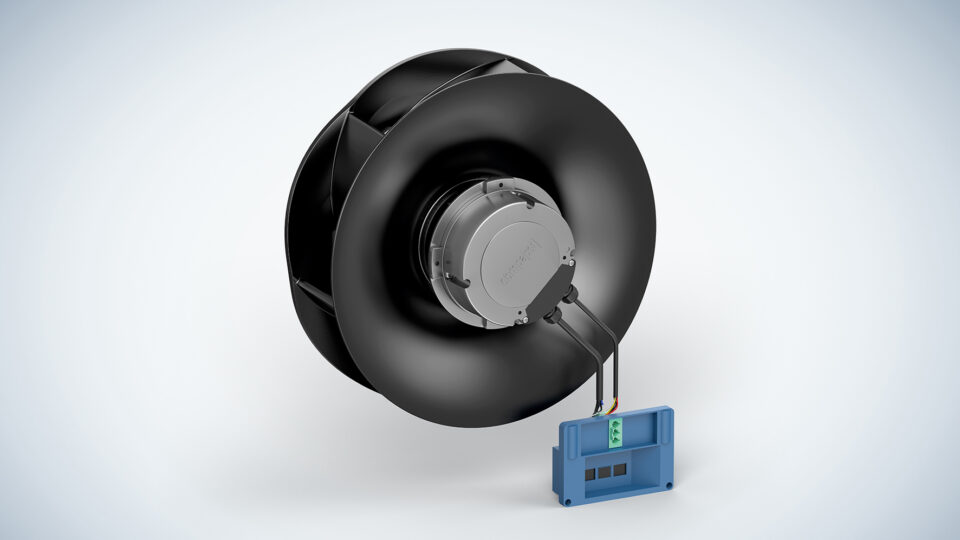

As the “heart” of the FFU, fans play an important role in cleanroom technology. The latest generation of RadiPac EC centrifugal fans from ebm-papst are therefore specially designed for this area of application. Not only do they supply the air volumes of up to 2,330 m³/h that are standard for the various FFU sizes, with sufficient pressure reserves for recirculated air operation in cleanrooms, but they also have efficiency levels of over 60% thanks to EC technology and the latest generation of RadiPac impellers. Compared to the previous industry standard, this means a 10% reduction in power consumption. They are also 6 to 7 dB quieter than the commercial standard and so easily meet the strict noise protection requirements for production in cleanrooms.

(Image | ebm-papst)

Aerodynamically optimized impeller

The impeller with its five geometrically sophisticated impeller blades and developed according to the latest aerodynamic findings, plays an important role in this optimization. This blade geometry drastically reduces flow losses. The inlet ring was also designed for perfect interaction with the new impeller. The sophisticated impeller geometry not only reduces flow losses, but also noise generation.

EC motors: more powerful, more flexible and even more compact

The driving force behind the new RadiPac centrifugal fans are high-efficiency EC motors in the 170 to 500 W power range. Committed to system efficiency, the drive system consisting of motor and integrated power electronics is individually adapted to each fan and optimized for the respective operating range. The design and functionality have also been updated to the latest generation and a MODBUS interface with DCI addressing has been added. An integrated resonance sensor will also be available as an option in future. This resonance sensor measures oscillations and vibrations in real time and can therefore detect imbalance caused by dirt, for example, and then send a message before the fan is damaged.

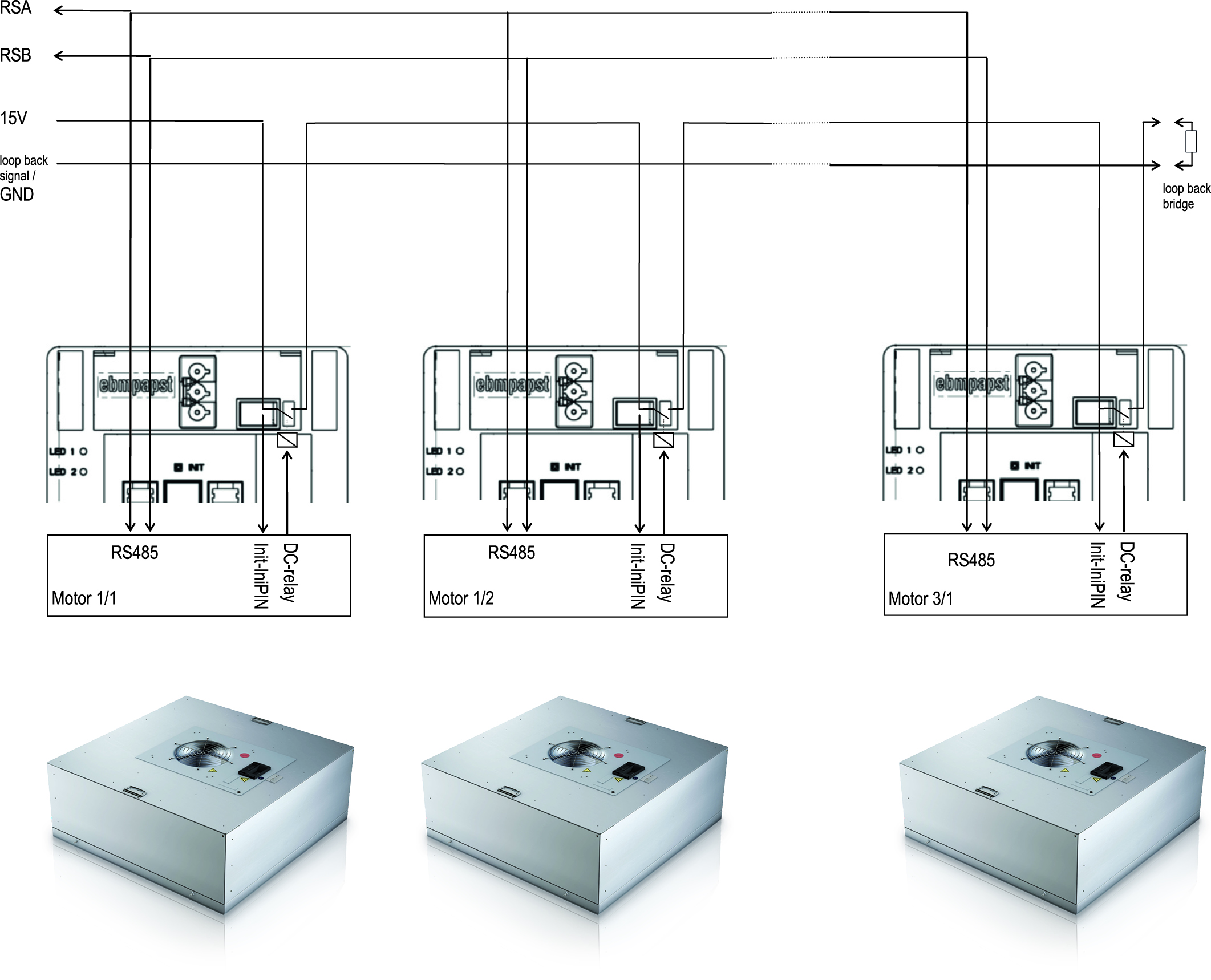

Fast commissioning – MODBUS RTU with auto addressing

The air supply in a cleanroom is not usually a standalone solution. Instead, it is integrated into the entire automation process and its PLC and SCADA systems. Just like all other sensor and actuator information, the fans of the FFUs have to be integrated into the system network, and their status information must be provided to the controls and visualization systems. The initial commissioning of a cleanroom system requires a significant output of time and money. Based on user reports, the time required to manually connect an FFU data point is around five to ten minutes. The more fans there are in use, the more potential there is to make savings. An additional accessory can help as a first step: Connector panels for bus and power distribution, which can be used to connect up to 64 fans in series per channel. In addition, the new RadiPac fans are not only available with a digital ebmBus or MODBUS-RTU interface, but also with auto addressing, which significantly reduces commissioning costs.

A master/slave-based bus always requires unique slave addresses. The fans are usually delivered with an address that is preset in the factory, which is always the same (e.g. slave ID = 1). Therefore, the addresses must be assigned a unique address during commissioning for operation in the network group, preferably in the order of the MODBUS cabling. This time-consuming process is now automated by what is known as DCI (daisy chain interface) addressing, which significantly reduces the time required for commissioning.

DCI addressing using MODBUS/DCI as an example – How it works

A fan equipped with a DCI is addressed by a hardware signal (15 V/24 VDC) via an “Init pin” on the RJ45 network plug, and thus temporarily assigned the slave address 247. Only the unit activated in this manner “listens” to messages sent to this DCI address 247 and accepts a new MODBUS address sent from the master to this slave. Once this fan has been successfully re-addressed, its DCI relay is switched on and the “Init pin” (15 V / 24 VDC) is switched to the next fan module in the chain. This fan is now activated via the hardware signal (“Init pin”) and the addressing continues as described above. If the cable diagram is known, the position of the fan unit in the cleanroom ceiling can be determined via the cable routing. Manual assignment of the fan address to the installation location is no longer necessary; the master controller takes over the complete addressing and localization of the fans installed in the FFUs in the cleanroom ceiling. There is a significant reduction in the time and costs of commissioning.

The right accessories are crucial

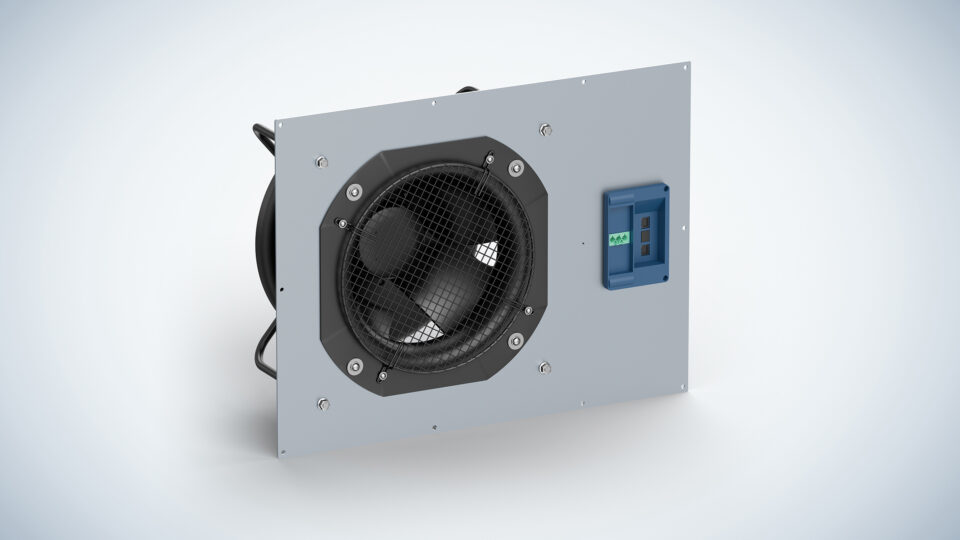

Good impellers are always sensitive on the intake side. If faults occur here, they are often unable to fully exploit their advantages. Reasons for this include ceiling designs that only allow lateral intake, and pre-filter boxes or mounted coolers that obstruct the inflow. This is where the right equipment, tailored to the impellers and incorporating many years of experience in ventilation applications, can help. After all, with fans it is always important to be aware of the system concept and the application-specific environment. One example is the closed FlowGrid air inlet grill. This acts as a kind of rectifier that reduces noise-generating turbulence in the inflow without changing the air performance or power consumption. The fans are then even quieter, which benefits ventilation applications as well as many others. However, it can also be used as contact protection by clipping in an additional guard grill inlay.

(Image | ebm-papst)

The fans are available both as a complete plug & play unit and as individual components, allowing users to combine the impellers with their own solutions. With an installation depth of 190 to 275 mm and diameters of 280, 355 and 400 mm, complete devices are very compact, meaning they can be easily accommodated even in tight installation spaces and are therefore also suitable for retrofit applications. They meet all the regulations required for cleanroom use, thereby providing users with assurance for use worldwide, both in Europe and North America as well as in the Asian market.

Leave a comment