Energy-efficient air-conditioning technology with modern GreenTech EC fans

Last year, the Solar City housing complex in the wine-growing region of Satigny was awarded the Swiss Solar Prize 2011 in the category “Energy Systems for Renewable Energies” for its eco-friendly energy and heat generation. 80% of the energy needed is generated by the complex’s own solar system. An important basis for the efficient us of regenerative primary energy is provided by the modern air-conditioning equipment employed for ventilating and heating the complex. When the windows are closed, it provides for a requirement-orientated air exchange and optimum air conditioning. The high-performance and yet energy-efficient fans with GreenTech EC technology supplied by ebm-papst which are employed in the HVAC systems make a major contribution to this.

The Solar City complex, which was completed in 2010, consists of four large buildings containing a total of 78 housing units and a large underground garage on two floors. The joint project between the company ERTE Ingénieurs Conseils SA from Geneva and the vintner family Bonnet from Satigny was constructed to the Minergie S standard. Minergie is the highest energy standard in Switzerland for low-energy housing and is roughly comparable with the German standards for energy-saving houses KW40 (for new buildings) and KW60 (for refurbishing older buildings).

With the power of the sun against frost

Around 1,160 m² of unglazed, walkable solar collectors have been fitted to the roofs of the residential buildings. These have been designed to generate energy even in unfavourable conditions

As the name suggests, the Solar City social housing project relies heavily on the power of the sun. Around 1,160 m² of unglazed, walkable solar collectors have been fitted to the roofs of the residential buildings. These have been designed so that they are still able to generate energy when conditions are less than optimal, even when it is raining, snowing or in moonlight. That enables the thermal solar system to generate some 80% of the total heat energy required. Green electricity from the grid accounts for the remaining 20%. Solar City employs an ingenious combination of direct hot water generation and heat pumps without additional expensive seasonal reservoirs or geothermal energy generation with underground probes. This was an important argument for the nomination for the Solar Prize.

The efficiency of the concept has now been proven in practice. At the start of 2012, during the almost Siberian cold spell, it was really put to the test. With temperatures averaging -11 °C and 15 cm of snow on the solar collectors, it was still able to heat the complex without difficulty. The 55 °C required in the boilers was achieved. The temperatures inside the apartments was a comfortable 21 to 22 °C. The residents had ample supplies of hot tap water. The additional electric heating elements which had been installed in the boilers for use in worst-case conditions were not employed even once. Despite the frosty temperatures outside, none of the residents had to freeze.

Ventilation concept saves energy and enhances living comfort

The RLT units of the type Optima ME from the company Bösch are compliant with the latest findings in the field of energy and hygiene, and satisfy all relevant standards which are applicable today for minimum energy equipment

Such an energy concept cannot work without controlled living room ventilation. A partially centralised system was chosen for the ventilation and air conditioning of the apartments. Here, the four buildings were split into ten sections, all of which are identical in their construction, and supply up to eight housing units. Each section comprises a unit for controlled living room ventilation and heating, a heat pump and a separate hot water reservoir. The energy consumption is individually recorded for each housing unit. The recorded operating data for the complete complex are sent by internet to the University of Fribourg for evaluation.

The centrally installed RLT units of the type Optima ME, supplied by the company Bösch (see box text 1) are responsible for a comfortable living climate in each section. These were designed specially to comply with the Minergie standard. The new line of units (see Fig. 3) with air performance of 400 to 7,000 m³/h are compliant with the latest findings in the field of energy and hygiene, and satisfy all relevant standards which are applicable today for minimum energy equipment. The design of the air conditioning equipment plays a decisive role here.

Energy-efficient centrifugal fans

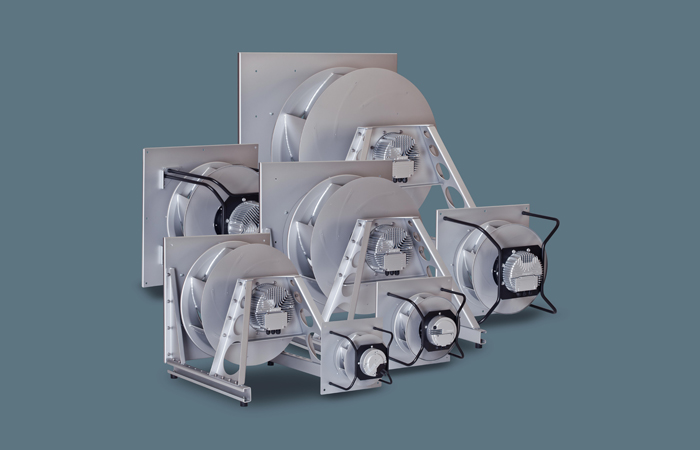

Backward curved fans with GreenTech EC technology provide for the necessary air flow in the centralised air-conditioning units

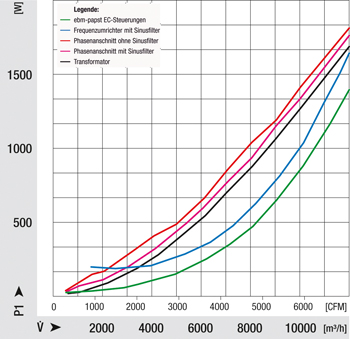

Large-area, humidity-resistant fine dust filters made out of pleated glass fibre material of class F7 pursuant to EN 779 with a protection rating of more than 60% provide for a high level of air cleanliness and guarantee a healthy room climate even when the outside air is polluted with fine particulate matter. The ultra-efficient heat regeneration system (the residual heat coefficient ɸ is greater than 80%) guarantees an optimal re-use of the heat in the exhaust air. The heating of the fresh air, which is needed at very low outside air temperatures, is achieved with a PWW (pump/warm water) register from the heat pump. To generate the necessary ventilation and air extraction flow, two centrifugal fans are used in each of the units. These are highly energy-efficient and are regulated extremely economically (see Fig. 4). They are taken from the product range of motor and fan specialist ebm-papst and are specially designed for use in ventilation and air-conditioning technology. Different versions ensure that the optimum fan solution can be found for every air-conditioning unit. For example, in the central air-conditioning systems in Solar City, Bösch employs centrifugal fans of size K3G280 with backward curved blades. These fans work chiefly by suction, do not require a scroll housing and have a high level of hydraulic efficiency. Furthermore, the GreenTech EC technology also means a whole lot more other advantages.

Freely adjustable controls and pleasantly quiet

Because the EC motors work so efficiently, they consume substantially less energy that conventional AC drives

The EC motors that power the fans feature an integrated electronic control system that allows the speed of the fan to be adapted precisely to what is actually required. Requirement-orientated operation can be controlled either with an analogue 0-10 V signal or via a digital RS485 interface. Because the motors also work with great efficiency, they consume substantially less energy that conventional AC drives, not just at full load but also in part-load operation.

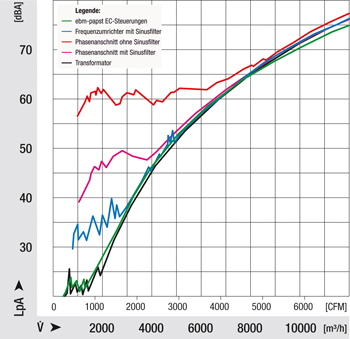

At the same time, they create practically no motor noise. In contrast, asynchronous motors driven by a frequency inverter, particularly under partial load, produce resonance noise that results in the typical unpleasant motor hum. This would certainly not provide a pleasant living environment. The residents of Solar City have nothing to fear. The air-conditioning units are equipped with fans powered by pleasantly quiet GreenTech EC technology. These are practically inaudible in the apartments and on the stairs.

Another advantage of these fans is their compact design. The electronically commutated external rotor motor is directly integrated into the impeller, which reduces the installation dimensions. A belt drive between the motor and the fan, which is commonly used otherwise, is not necessary. This reduces not only the required installation volume – always desirable for the air-conditioning units made by Bösch – but also the associated installation complexity. At the same time, fewer parts are required which are subject to wear. This keeps service costs low over the long term and thus saves money for the operator. Moreover, the design of the fans permits hygienic maintenance.About Walter Bösch GmbH

Walter Bösch GmbH & Co KG is based at Lustenau in the Austrian state of Vorarlberg and has been in existence for more than 80 years. Started as a one-man operation, the company has grown into a medium-size organisation with around 650 employee. It is one of Austria’s leading companies in the fields of heating, air-conditioning and cleaning technology. Its air conditioning and ventilation systems are custom-built to cover the dehumidification and ventilation requirements of a small hotel bathroom or the air conditioning requirements of industrial production halls and clean rooms. They can be installed in the basement or weatherproof versions can be fitted on the roof. Intelligent control solutions and complete systems with integrated heating and hot-water production bear witness to the synergies between the different company divisions.

Leave a comment