The climate and the ambient air quality both have a great effect on concentration, health and wellbeing, so it is important to have good ambient air, for examples in classrooms. Window ventilation used to be common practice, but is effectively banned today from the perspective of energy efficiency, meaning that climate control systems are needed that provide the necessary air exchange and optimum air-conditioning even with windows that are closed and air-tight. That by no means applies only to new buildings. Such concepts can also be integrated in conversions and renovations. The result is low energy costs and good ambient air quality. The EC fans employed in modern air-conditioning systems are high-performance and at the same time energy-efficient. The application described below provides an excellent example.

In the village of Höchst in the Austrian state of Vorarlberg, the former secondary school was restructured to the “New Middle School” in 2008. Today, some 400 pupils attend a total of 16 classes. Attached to the building is a public library and a multimedia room. Höchst municipal council, which runs the school, recognised early that a very large proportion of the council’s expenditure was attributable to energy costs. Consequently, when the school was rebuilt, high priority was attached to reducing costs and to exploiting energy-savings potential.

Rebuilding as a chance to save energy

With a depth of just 360 mm, each compact unit delivers a air flow of 1500 m³/h and works with a highly efficient heat recovery system.

The school building was to become a low-energy building after conversion and renovation. A highly ambitious project for which the targets were an energy coefficient Ew of 40 kW/m²a and a standardised air quality with a maximum CO2 concentration of 1200 ppm. What do these figures mean? That’s easily explained. The energy coefficient Ew is the most commonly used comparison figure for describing the thermal quality of the building shell. It tells us how much energy is needed per year to air-condition one square metre of floor space. For values less than 50 kW/m²a we speak of low-energy buildings. For values below 15 kW/m²a, we speak of passive buildings. The CO2 content in the air has a decisive affect on personal wellbeing. At concentrations below 0.1% (1000 ppm, parts per million) we feel good; at values above 0.2% uncomfortable. A maximum concentration of 1200 ppm is thus a good and realistic limit value for the air quality in classrooms.

Achieving the targets with respect to energy coefficient and at the same time maintaining good ambient air quality is only possible with an airtight building and a controlled ventilation system. Together with the company Bösch, a ventilation concept comprising centralised and semi-centralised air-conditioning units was developed. This was specially tailored to the building’s conditions.

Ventilation concept adapted to the architectural features

The flat, ceiling-mounted air-conditioning units employ forward curved centrifugal fans with GreenTech EC technology.

For the air-conditioning and fresh air supply to the classrooms, a total of seven ventilation and air extraction units were installed in the ceilings of the class anteroom on each floor (see Fig. 2). These compact units, which are just 360 mm flat, supply a volume flow of up to 1500 m³/h and work with a highly efficient heat recovery system (heat recovery coefficient > 70%) to guarantee good reuse of the heat in the exhaust air. At very low outside temperatures, the fresh air is heated up as necessary by a PTC electric air heater. Class F7 fine dust filters pursuant to EN 779 with a protection rating of more than 60% provide for a high level of air cleanliness in the classrooms and guarantee a healthy room climate even when the quality of the air outside is poor.

Because of its different opening hours, and because of the air volume it needs on account of its size, the library is equipped with a separate, centralised ventilation and air extraction unit that delivers up to 4000 m³/h. The media room and the other classrooms in the new extension are also supplied by their own ventilation and air extraction unit. This is configured for a maximum air performance of 7,000 m³/h. All ventilation and air-conditioning units are integrated into a single intelligent central building control system. The air-conditioning is controlled according to requirements in accordance with the current CO2 concentration. The conversion has proven worthwhile for the village of Höchst. How much energy the system consumes was closely monitored for two full years by the independent “Energieinstitut Vorarlberg” (Vorarlberg Energy Institute). The low energy consumption figures required were confirmed.

Energy-efficient centrifugal fans in GreenTech EC technology

Backward curved fans with GreenTech EC technology provide for the necessary air flow in the centralised air-conditioning units.

A decisive contribution to this success can be attributed to the design of the air-conditioning units. To generate the necessary ventilation and air extraction flow, two centrifugal fans are used in each of the units. These are highly energy-efficient and work extremely economically. They are taken from the product range of motor and fan specialist ebm-papst Mulfingen and are specially designed for use in ventilation and air-conditioning technology. Different versions ensure that the right fan solution can be found for every air-conditioning unit. For example, Bösch employs forward curved centrifugal fans with GreenTech EC technology and a diameter of 225 mm from ebm-papst in its ceiling-mounted flat air-conditioning units (see Fig. 3). The characteristic features of forward curved fan blades are an especially low noise level and relatively high air flow with a low static pressure increase, plus they require relatively little installation space. Backward curved design versions provide for the necessary air flow in the centralised air-conditioning units (see Fig. 4). Centrifugal fans with backward curved blades are used primarily for intake suction and do not require a scroll housing. They have a high level of efficiency. In both cases, the user benefits from the numerous advantages offered by ebm-papst’s GreenTech EC technology.

Quiet operation according to requirements

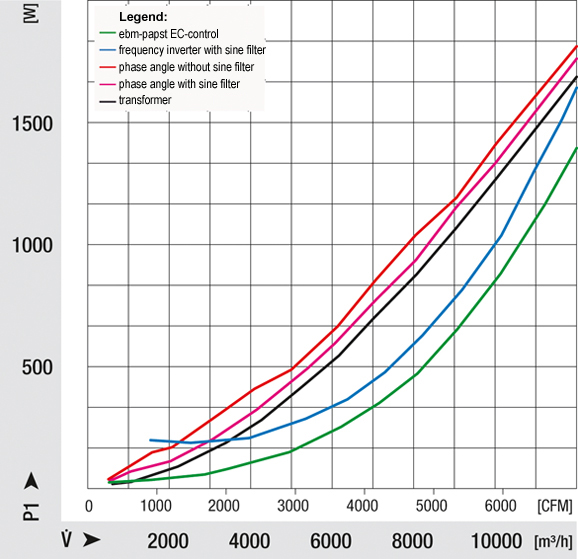

Because the EC motors work so efficiently, they consume substantially less energy that conventional AC drives.

The EC motors that power the fans feature an integrated electronic control system that allows the speed of the fan to be adapted continuously to requirements. Demand-orientated operation can be controlled either with an analogue 0-10 V signal or via a digital RS485 interface. Because the motors also work with great efficiency, they consume substantially less energy that conventional AC drives (see Fig. 5). However, these potential energy savings are realised not only when operated under full load, but also primarily when operated under partial load. When operating under partial load, EC motors lose far less efficiency than asynchronous motors of the same output. Also very important with respect to ventilation systems in schools is the noise level, especially if the units are installed directly in front of the class anteroom.

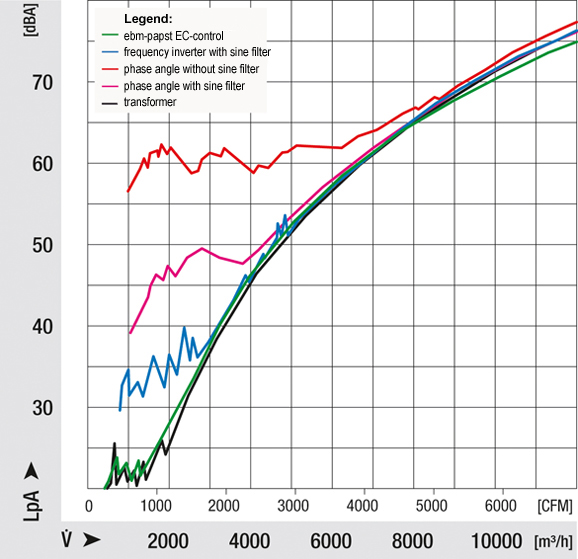

Here too, EC drives are the better choice, because the motors produce practically no noise (see Fig. 6). In contrast, asynchronous motors driven by a frequency inverter, particularly under partial load, produce resonance noise that results in the typical unpleasant motor hum. This would certainly not provide a pleasant environment for the teachers and students. The students at Höchst Middle School have nothing to fear. The air-conditioning units are equipped with fans powered by pleasantly quiet GreenTech EC technology. These are practically inaudible in the classroom. The 28 dBA noise level officially specified in the classroom is observed.

Compact design, easy installation and long service life

Another advantage of these fans is their compact design. The electronically commutated external rotor motor is directly integrated into the impeller, which reduces the installation dimensions. A belt drive between the motor and the fan, which is commonly used otherwise, is not necessary. This reduces not only the required installation volume – always desirable for the air-conditioning units made by Bösch – but also the associated installation complexity. At the same time, fewer parts are required which are subject to wear. This keeps service costs low over the long term and thus saves money for the operator.

we use EC fans of 2000m3/hr@12mmS.P.capacity for demand controlled ventilation purpose to maintain CO2 levels in AIR CONDITIONING areas.AIR QUANTITY varies with reference to PPM levels of CO2.Pl.suggest honeywell make most suitable CO2 sensor and our requirement is as below.

at 700ppm of CO2 LEVEL IN return air path EC fan should deliver 1000cfm

at 600ppm of CO2 EC fan should deliver 750cfm

at 500ppm of CO2 EC fan should deliver 500cfm

at 400ppm of CO2 EC fan should deliver 300cfm

Pl.give control wiring diagram and logic of operation