Refrigerators have long become an established fixture in the kitchen. They make it easier to keep supplies and ensure that many foods stay fresh longer. Unfortunately, conventional refrigerators also have disadvantages, and thus compromises must often be made for the cooling temperature of various foodstuffs such as meat and vegetables. Ice formation on the evaporator in the freezer compartment must be removed by manual defrosting, and the contents of the refrigerator and freezer stored elsewhere during this process. A new concept for refrigerator/freezer combinations with integrated fan provides help here. It allows better temperature distribution and prevents ice formation on the foodstuffs stored in the freezer compartment. An automatic defrost feature also makes the previous maintenance effort unnecessary.

Foodstuffs age, meaning that they decompose chemically into other components. A rule of thumb of organic chemistry is that for each 10 °C temperature increase, the reaction speed doubles. Thus many foodstuffs stay fresh longer at a lower temperature. Because foods such as fruit or vegetables are still “alive”, however, the temperature must not become too low. We all know that potatoes taste “sweet” when they have been subjected to frost. Therefore, the objective is to provide optimum temperature control for each foodstuff cooled. Siemens, the specialist for white goods, has come out with a new series of built-in refrigerator/freezers that address precisely this problem. The new appliances cool exactly to the setpoint and prevent the formation of unwanted ice with the automatic NoFrost feature. A specially adapted fan (Figure 1) provides ideal air circulation. To adapt these components optimally to the conditions, the developers brought the motor and fan experts of ebm-papst Landshut on board with them. This resulted in a new NoFrost blower design that keeps the freezer compartment reliably free of ice.

Customised cooling

Saving energy is foremost on everyone’s mind. Therefore, the new cooling units work in class A++. Despite this, improved insulation, in conjunction with a new cooling concept, provide plenty of useful space for the foodstuffs (Figure 2). The refrigeration chamber can be flexibly adapted to the quantities of each food, and continuously adjustable easyLift glass plates and flexible door compartments fit the food and beverage items stored. Sensor-controlled cooling automatically adjusts the output of the state-of-the-art cooling system. Thus when new foodstuffs are stored, they are quickly brought to the necessary storage temperature and products that are already deep-frozen are prevented from defrosting. A modern LED lighting system prevents unnecessary heat in the refrigeration chamber and thus saves additional energy costs.

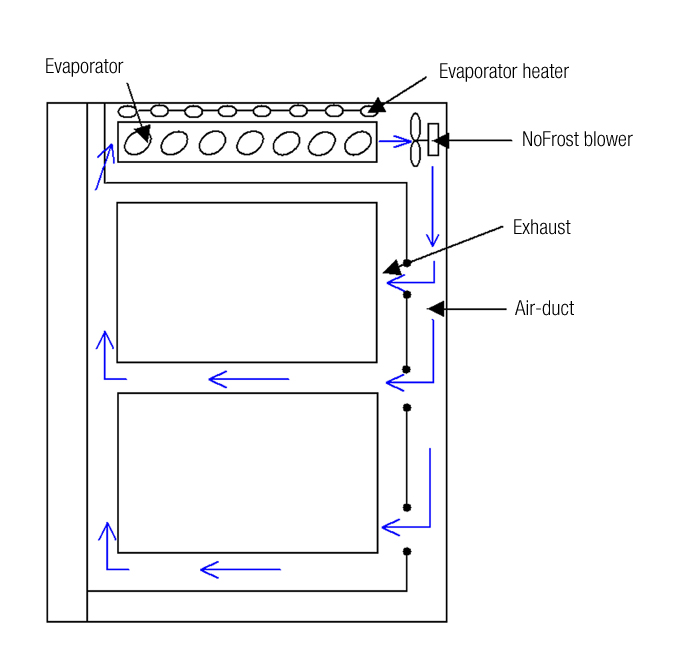

However, even the best innovation cannot change the laws of physics. Warm air always contains more water vapour than cold air. In nature, this means fog or rain when the air cools; in the refrigerator, this means condensation. Particularly in the freezer compartment, the condensed water accumulates on all cold surfaces as a layer of ice. This effect cannot be prevented entirely, but it can be controlled! Thus the cooling experts at Siemens, together with ebm-papst Landshut, developed an optimum combination of air conduction and NoFrost blower in the interior of the freezer compartment. This ensures that the warm air that enters is guided quickly towards the extra-cold condenser surface designed for this purpose. There, it sheds its excess water through condensation. Thus the foodstuffs and the rest of the surfaces of the appliance remain free of condensate and ice.

Fan ensures dynamic cooling

Fans at the specific location draw moist, warm air over the cold evaporator to be dehumidified

The interior of the freezer compartment contains a fan that is specially optimised for this application. It draws the moist, warm air in across the cold evaporator surface, thus generating a circulating air flow (Figure 3). There, the water vapour condenses and solidifies immediately into ice. The dried air then escapes in a targeted manner in certain areas of the refrigerator to attain perfect temperature stratification. When it contacts the foodstuffs, it heats up slightly and absorbs minimal quantities of moisture during the normal refrigeration process, then deposits it at the evaporator. Result: the interior remains constantly free of condensate and ice. If the evaporator then ices up, it is defrosted automatically, the condensate is removed and the cycle begins again.

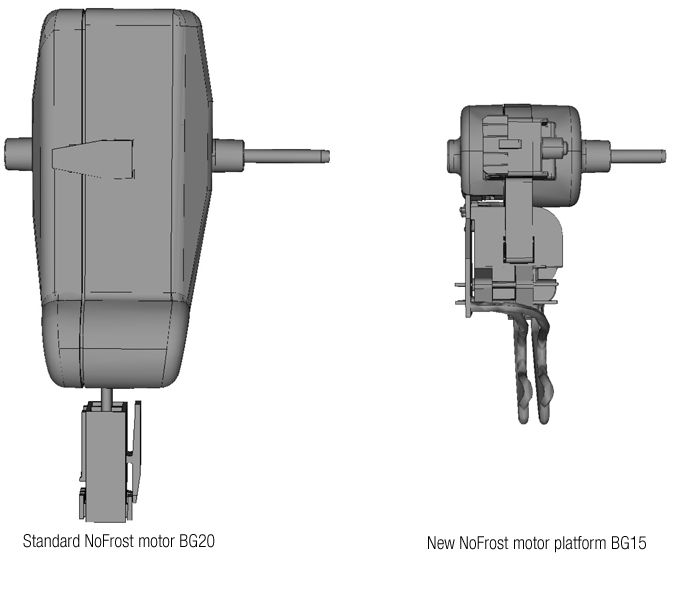

The new size 15 motor platform features outstandingly compact installation dimensions and works with minimal power consumption at low temperatures

Of course, such an application places stringent demands on the fan used. An optimum aerodynamic design and whisper-quiet drive are required. In addition, a long service life, which for modern appliances is significantly over 10 years, and extremely efficient use of energy are required, as after all, the drive motor is in the cold area. Waste heat that is not created there does not have to be removed by cooling. The fan experts solved the problem of aerodynamics in numerous test bench trials. So that the drive could also be ideally matched, they use a new motor design, the size 15. The drive is specially optimised for the requirements for operation at low temperatures and for minimum power consumption, while simultaneously featuring especially small installation dimensions (Figure 4). Thus the entire centrifugal compact fan measures only approx. 135 mm x 64 mm (diameter x height), which makes it possible to gain extra useful space in the freezer compartment.

New size 15 motor platform

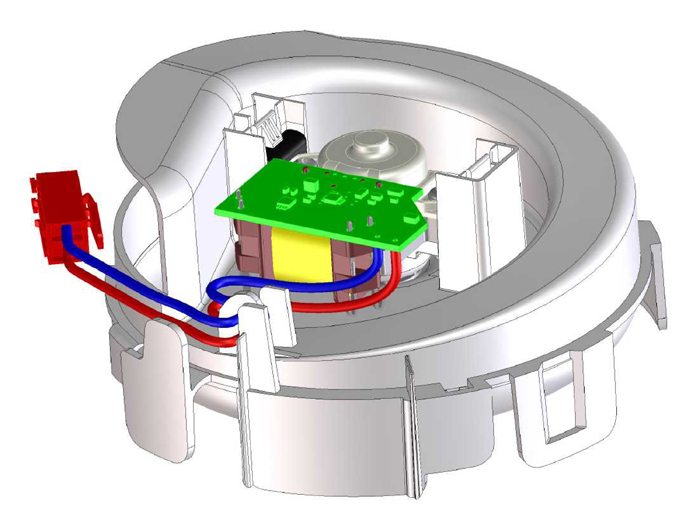

The new size 15 motor platform is a brushless direct current motor. It is designed for a variety of voltages. In the present case, the fan is operated at 9 VDC. Other voltage versions (12 VDC or 24 VDC) are likewise possible. The availability in various overall motor heights covers a wide power range, making the motor series highly versatile in use (even beyond the domestic refrigerator/freezer area). The motor electronics can be adapted to a wide variety of customer requests. The speed of the drives, for example, can be easily regulated for different cooling concepts. The internal closed-loop speed control means that the motor maintains the set speed constantly. Various closed-loop speed control concepts can be offered. The bearing and lubrication of the shaft is specially matched to the low temperatures and long service life. At the same time, the special bearing and an optimally matched electrical configuration reduce the power requirement of the motor, which improves the efficiency of the refrigerator/freezer.

Its special design and extremely small dimensions allow the motor to be integrated into the specific fan design in a space-saving manner

Its special design and extremely small dimensions allow the motor to be integrated into the specific fan design in a space-saving manner. All important parameters are verified during development and tested later under real-world conditions during quality control in the ebm-papst group’s in-house test lab. Thus the performance data for service life, power input or air volume and pressure increase are not just theoretical values, but specifications that can be verified in real-world applications. The user can therefore be assured that values will be attainable in his or her product as well.

Summary

Improvements in refrigeration require new methods and solutions. For uniform or stepped temperature distribution, an internal air circulation is especially suitable. In addition, this prevents the problem of unwanted condensate and ice formation in the freezer. Fan solutions adapted to the special conditions in the low temperature range and the operating noise standards for household appliances are the ideal means to this end.

Leave a comment