The heart beats, wings vibrate, music is played and heard – life without vibrations is difficult to imagine. Even though vibrations are everywhere and have beneficial uses, they can also be destructive. Poorly balanced car wheels can cause the steering wheel to shake, and vibrations can loosen screws or damage ball and roller bearings.

Even large structures can collapse when they are subjected to rhythmic vibrations at their resonance frequency, because then a system capable of vibration can absorb large amounts of energy, which can lead to catastrophic failure. That was what happened when the Tacoma Narrows Bridge collapsed in 1940 after being forced into oscillations by unusual wind conditions, only a few months after its dedication.

Conditions of installation matter

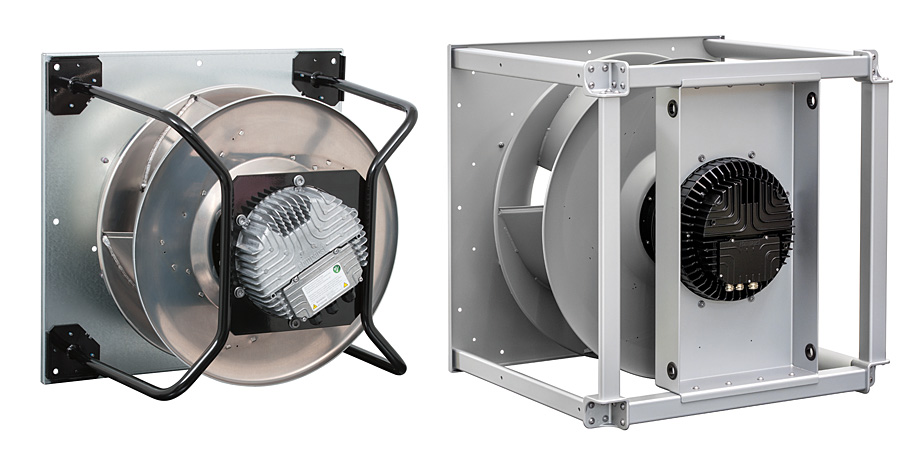

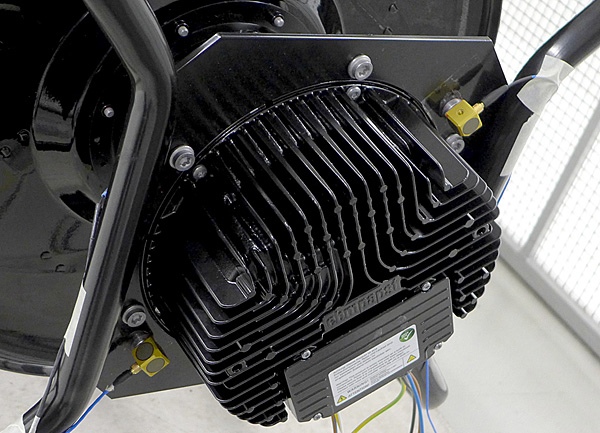

Fans are not immune to resonance-related damage either, even though their manufacturers use state-of-the-art techniques to balance them precisely during production, as in the RadiPac series from ebm-papst (Fig. 1). A crucial role is played by the conditions of a fan’s installation, which unfortunately can neither be predicted nor allowed for.

When a fan is installed in a piece of equipment, a new configuration arises that is capable of vibration at a specific structural resonance frequency. In addition, the fan’s resonance characteristics change when it is fixed in position. With the speed-controlled operation that is now widespread, the likelihood that a fan will at times be operated at resonance increases considerably. Other factors are transport and handling. For example, the impeller may not be damaged by impacts, unsuitable lifting equipment and the like, and fans may only be placed on suitable surfaces.

It is not unusual for vibrations to be transmitted from external system components to the fan, for example from a compressor. During operation, vibrations can result from imbalances caused by dirt on the impeller or from flow-related oscillations, for example if the gap between the impeller and the housing is too small or unfavorable intake conditions lead to turbulence.

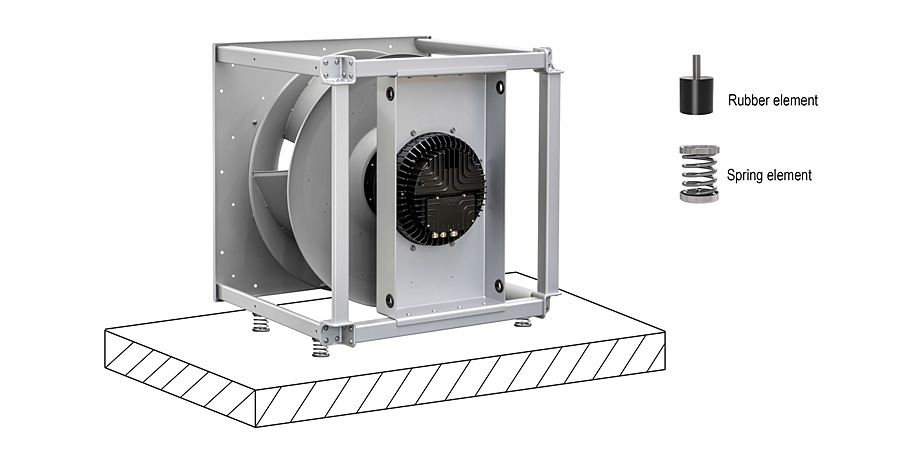

Vibration-absorbing elements and speed range

UVibration-absorbing elements (Fig. 2), such as appropriately designed springs or rubber elements, help to isolate fans from vibrations in their surroundings. However, certain things need to be considered when selecting them. In addition to the fan system’s natural frequency, the addition of vibration-absorbing elements results in a new spring-mass system with its own resonance frequency.

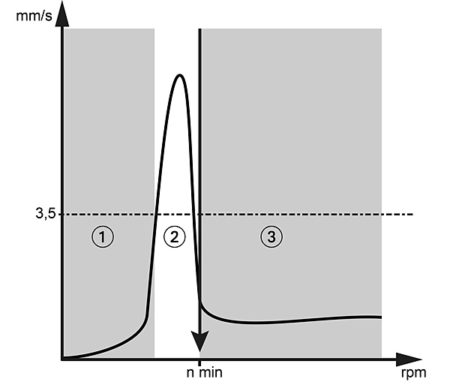

Fig. 3: Basic trace of vibration speed over the speed range of a fan with vibration-absorbing elements: range below the resonance frequency (1), range near the resonance frequency (2) and range above the resonance frequency (3). (source: ebm-papst)

When a fan starts up, it passes through three vibration-relevant speed ranges (Fig. 3). In the range below the resonance frequency, the vibration severity is below the allowed limit of 3.5 mm/s (according to ISO 14694). Operation of the fan is possible in this range, but the vibration-absorbing elements have no effect for physical reasons.

. In the neighboring resonance speed range, the vibration velocity is sometimes well above the allowed limit. There is no immediate damage to the device, but lengthy operation in this range will shorten the overall service life. Besides that, high noise levels are reached. This speed range should therefore be passed through as quickly as possible, and sustained operation there should be absolutely avoided.

The speed range in which the vibration level is well below the limit starts sufficiently far from the resonance peak. Only in this range, above the minimum speed, can the vibration-absorbing elements isolate the fan from the vibrations of its system or building. To select the right vibration-absorbing elements, the operating speed of the fan in its application must be known. For every fan, one can find correctly sized vibration-absorbing elements and the associated minimum speed. If others are to be used, the aforementioned principles need to be considered.

Protecting against damage with vibration measurements

As explained, there is a host of reasons and effects that can lead to excessive vibration levels, but they are not all predictable and are often unavoidable. Following the installation of a fan, vibration measurements and/or a search for resonance points should therefore be performed throughout the entire speed control range. This provides an overall impression of the system’s vibration characteristics and reveals all unpredictable effects and also possible mistakes made during the run-up to commissioning.

With a view to achieving longer service life, this is necessary as the consequences of excessive vibration severity due to a structural resonance or unsuitable vibration-absorbing elements can be disastrous. Moreover, incorrectly dimensioned vibration-absorbing elements do not adequately prevent the transmission of structure-borne noise.

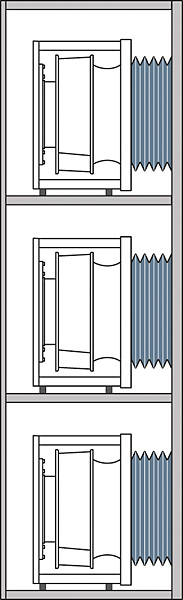

Fig. 6: Proper setup for multiple fans: Each fan rests on specially designed vibration-absorbing elements (such as springs or rubber elements) on a sturdy framework that is firmly fastened to the floor. (source: ebm-papst)

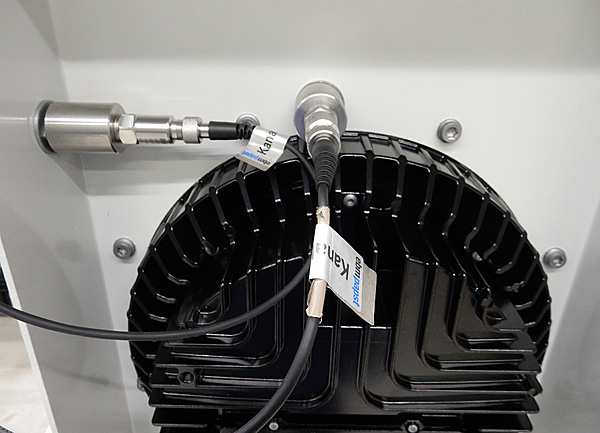

This may cause the entire ventilation system to vibrate, resulting in a high noise level and leading through feedback effects to bearing damage in the fan. Since measurement results are also strongly dependent on the positioning of the vibration sensors, the sensors have to be attached as shown in Figs. 4 and 5. Because of possible effects during operation, such as the formation of dust deposits, this vibration check needs to be performed repeatedly, at least within the intervals specified in the operating instructions.

On the safe side

For vibration analysis of its RadiPac centrifugal fans, ebm-papst recommends measuring vibration in all three axes (Fig. 4), or at least in two axes (Fig. 5) radial and axial to the axis of rotation, using a typical vibration measuring unit. If measurements reveal ranges with excessive vibration, it may be possible to rebalance the fan in the field. Ideally, the vibration measurement unit can assist in such measures. If such measures are insufficient, the system can be subjected to design modifications such as the addition of reinforcement braces.

One can also verify that the vibration-absorbing elements are working correctly and the fan is not operating below its minimum speed. If multiple fans are in use, they should be adequately spaced and kept from influencing one another (Fig. 6).

Alternatively, ranges identified by the measurements as having excessive vibration levels can be avoided using the system’s speed control. When needed, the experts at ebm-papst are available to advise customers, because considering the vibrational aspects when installing a fan is always worthwhile. Properly installed fans work reliably throughout their service lives, unexpected failures are prevented, and users also benefit from lower noise emissions.

Leave a comment