Following the start of the economic boom in the late 1940s, construction activity across Europe surged. However, the huge demand for affordable housing meant the focus during this time was on building as rapidly as possible, with little consideration given to the energy balance. And this is now a problem. Since much of today’s housing stock dates back to between the 1950s and 1970s, 75 percent of the buildings in the European Union (EU) are not rated as energy efficient. According to the EU Building Directive, this needs to change. By 2035, the average primary energy consumption of existing residential buildings must be reduced by 22 percent. The ultimate goal is for all buildings to be climate neutral by 2050. However, energy-related refurbishments are both costly and time-consuming, resulting in considerable challenges for residents during the construction phase. So what can be done to change this?

The INFINITE project: systematic refurbishment

For the past five years, Fabrizio Miorin has been working hard on answers to this question. Miorin is the head of research and development at Vortice, an Italian manufacturer of ventilation systems and a contributor to the EU-funded INFINITE project. “Together with 20 partners from eight countries, including manufacturers of prefabricated houses, construction companies and universities, we are developing solutions to improve the energy balance of houses by refurbishing their facades without any significant intervention.” The aim of the project is to reduce refurbishment costs by up to 50 percent, shorten construction time by 54 percent and extend the service life of the refurbished buildings by an additional 50 years.

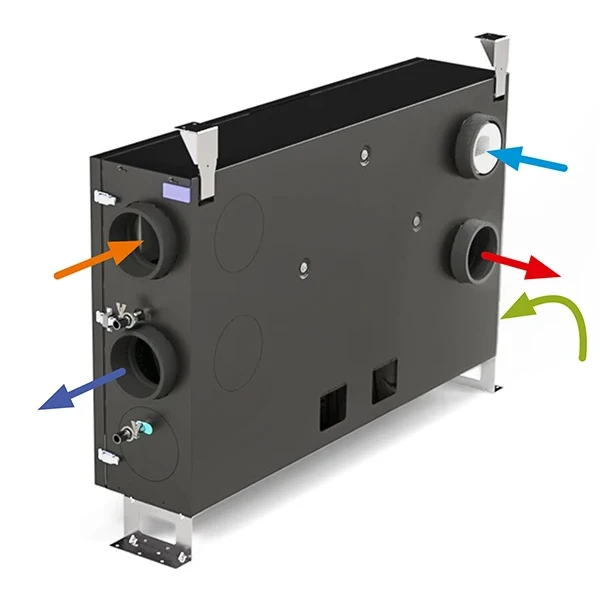

The idea is to use industrially prefabricated facade elements made from sustainable materials that can be easily attached to the existing wall from outside. A special feature is the development of modules that can be integrated into the facade elements using the plug and play principle, enabling them to perform other functions in addition to insulation. These include, for example, solar cells to produce electricity, plants to green the facades, smart windows that darken automatically in sunlight and even a ventilation, air conditioning and heating system for the homes. This is exactly where Vortice can contribute its expertise. The task of Miorin and his team of engineers was to develop a ventilation system that is narrow enough to fit the facade elements, consumes little energy and, above all, operates quietly. “The aim is that the ventilation system should not disturb residents,” says Miorin.

How the Vortice solution works

(Image | Vortice)

Integrated ventilation

Developing a standardized solution that meets these requirements is far from simple because every facade is a little different. Some buildings have balconies whereas others do not. There may be differences in the arrangement and size of the windows and also significant variations in the size of homes. “We analyzed the buildings in Europe in detail. In Eastern Europe, homes tend to be smaller than in the West. We need a solution that works for all houses. That is why the thermal unit is dimensioned for homes of 50 square meters. This gives us maximum flexibility,” explains Miorin. In the case of larger homes, additional facade elements are equipped with climate-control technology.

In collaboration with other project partners, Miorin and his team developed a concept that includes a heat pump to centrally produce heating or cooling for the entire building as required. The ventilation units supplied by Vortice distribute this to the individual apartments. However, they actually do a lot more. “We extract the thermal energy from the exhaust air and return it to the apartments via a highly efficient heat exchanger connected to the heat pump circuit. At the same time, we supply fresh air to all rooms,” explains Miorin.

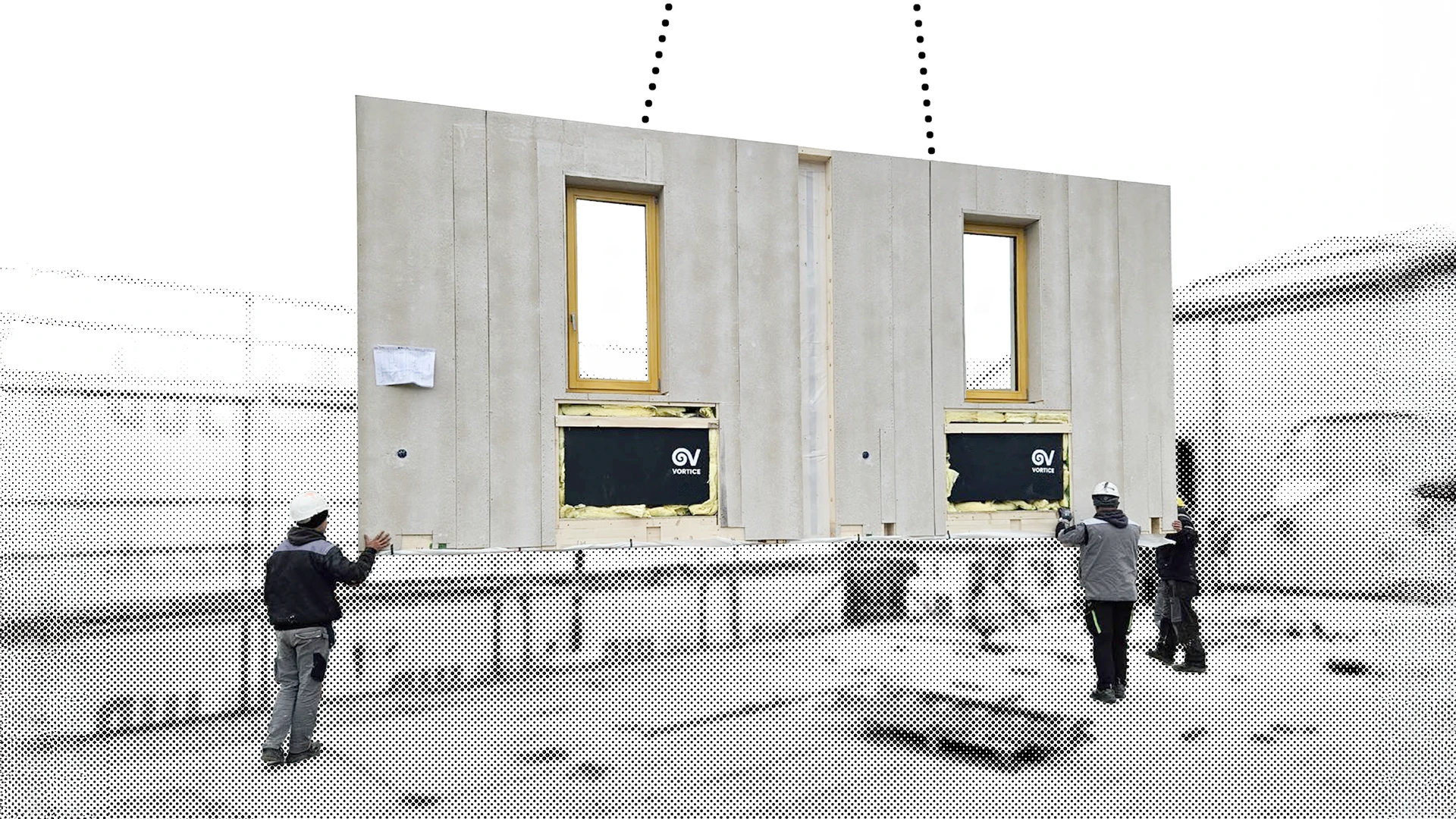

Two INFINITE pilot projects in Europe

a multi-purpose building constructed in the 1970s. As part of the refurbishment, new apartments are to be added to the building. The Vortice units have been integrated directly into the facade. (Image | Vortice)

In this way, the system saves more energy. Miorin needed two fans to implement this solution: One removes stale air from the rooms, while the other distributes fresh air and heat. When it came to choosing a manufacturer, the engineer did not have to think about it for too long: “We’ve been working with ebm-papst for many years. Particularly in projects like this, it’s important to have a proven expert to supply reliable and efficient products. And the collaboration is also very good at the personal level.”

Quiet and efficient RadiCal fans

Miorin’s inquiry landed on the desk of Carlo Paroni, Team Leader Air Conditioning & Ventilation at ebm-papst Italy. Decentralized ventilation systems are nothing new for Paroni because ebm-papst has developed axial and centrifugal fans for precisely this kind of application. What was new to him, however, was the way in which the ventilation systems were to be used: “This is an exciting and innovative project that offers great potential for saving energy in existing building stock. It’s a very good fit with our own corporate values.”

“Variable control of the fans means that our system can operate very precisely.“ Fabrizio Miorin, head of research and development at Vortice

Vortice chose two RadiCal fans for its system, which satisfy all the requirements that were important to Miorin: They are compact, energy-efficient, variable thanks to EC technology and extremely quiet, even at full power. Miorin explains: “Variable control of the fans means that our system can operate very precisely and deliver the output that is actually required.” Of course, energy efficiency is essential in a project that is intended to cut costs and protect the climate.

The reality check

Vortice’s ventilation solution still has to prove itself under real conditions on facades requiring refurbishment. To date, the facade elements have been tested in two pilot projects in Italy and Slovenia. The first analyses and findings are expected in 2026. If all goes well, it will soon be possible to install the prefabricated facade elements in many other buildings across Europe, thus enhancing efficiency and comfort. There are more than enough reasons to accelerate this process.

At present, the average rate of energy-related refurbishment in the EU is only about one percent. Miorin is convinced that the solution delivered by the INFINITE project can make an important contribution to climate protection. And he is already thinking about the next development: “I believe that decentralized heat generation is conceivable in place of a central heat pump.”

At a glance

The company

Vortice S.p.A., headquartered in Tribiano near Milan, was founded in 1954 and manufactures energy-efficient ventilation systems and heat recovery systems for industrial, commercial, and domestic applications. Today, the company is one of the global market leaders in this field and operates in over 90 countries.

The project

The INFINITE project is an initiative funded by the European Union as part of the Horizon 2020 research and innovation program. Its goal is to develop industrialized, integrated facade solutions for the energy-efficient renovation of buildings, thereby contributing to the decarbonization of Europe’s building stock.

Leave a comment