Every fan’s air performance, noise and efficiency depend on the geometry of the impeller, the housing components, the speed and the diameter. Theoretically, both centrifugal and axial fans can be used in air handling units (AHUs). In both designs, the air is drawn parallel to the axis of rotation. While the outflow for axial fans is primarily parallel to the axis, the air in centrifugal fans mainly escapes outwards and radially from the center, i.e. centrifugally.

In both designs, the air flow is also directly proportional to the speed, while the pressure increase rises with the square of the speed. Which is the better choice depends on the application involved. The installation and operating conditions are important factors for the fan to work at optimum efficiency and with minimal noise emissions.

Axial fans: a sensible solution?

Fig. 1: Differences in the characteristic curves of centrifugal and axial fans. (Graph | ebm-papst)

Axial fans work most efficiently when they convey air – for example via a heat exchanger – into the open at low back pressures. To achieve the best possible efficiency, an axial fan’s impeller should be positioned in a fan housing that has been aerodynamically optimized. Together with a front plate, this ensures the correct flow control and provides the separation required between the intake and outlet sides.

The characteristic curve of a typical axial fan is marked in blue in Fig. 1. Therefore, axial fans achieve optimum efficiency at high air flows and do so with minimal noise emissions. Axial fans are sensitive to inflow fluctuations without additional measures, such as an upstream guide vane. It is also often useful to have a discharge vane on the outlet side to optimize efficiency, which means more mechanical effort during the assembly and an increased overall length.

The outflow characteristics of axial fans are very focused compared to centrifugal fans, which is a disadvantage when applying air to downstream filters or heat exchangers. However, if the outflow goes directly into a duct network, this can be advantageous (Fig. 2).

Centrifugal fans: the better choice

Centrifugal impellers are intrinsically less sensitive to influences on the inflow and outflow sides. The development of RadiPac centrifugal fans from ebm-papst, specially designed for installation in AHUs, not only involved optimizing the energy efficiency and noise emissions of the impeller, motor, control electronics and housing: it also involved considering the actual installation conditions in AHUs. The result is clear: this choice of fan does not require large reserves to be prepared for installation losses. Furthermore, centrifugal fans without a scroll housing are particularly flexible when it comes to outflow variants out of the AHU. Since the fans apply air to a pressure chamber (pressure plenum), it is possible to connect to a duct network in virtually all directions without significant losses.

Fig. 2: Axial and centrifugal fans can be used in air handling units (AHUs). Centrifugal fans (left figure) ensure that the air is applied more evenly to downstream fittings (filters, heat exchangers) than with axial fans (right figure). The axial speed is presented in color. (Image | ebm-papst)

What is the definition of efficiency?

Theoretically, efficiency is defined using the quotient of output over input. In ventilation technology, the parameters are air conveying performance (air flow x pressure increase) divided by electrical power consumption. However, this information alone does not guarantee that the manufacturer’s specifications will be comparable. First of all, it is important to determine which components the fan concerned contains. If there is only a fan impeller, the efficiency values cannot be compared to the values of a complete fan consisting of control electronics (VSD), a motor and a fan impeller.

To obtain realistic information about efficiency levels, the entire fan unit has to be measured as a whole.

Simply multiplying the individual efficiency levels of the various fan components at their optimum point is not enough either. Although this is often done in practice, you cannot expect all the components used to work at their optimum efficiency when they are put together, especially considering that component manufacturers often only provide optimum efficiency values. It is difficult to obtain values for partial load behavior at a reduced speed. To obtain realistic information about efficiency levels, the entire fan unit has to be measured as a whole.

ηFan≠ηmaxMotor *ηmaxImpeller *ηmaxControl electronics

Back to the definition of efficiency. Air performance is defined by multiplying the air volume and the pressure increase. The air flow, i.e. the air volume, is provided by the air conveying task. The pressure increase required is found by determining the components that the air flow passes through, such as filters, heat exchangers and the connected air path. As a sum, this is the overall pressure. It is specified as static pressure and is used to select the fan.

Nowadays, the terms total pressure and total pressure increase are also common. The total pressure is the sum of the static pressure and the dynamic pressure and, therefore, is always higher than the static pressure alone. Therefore, this information should be treated carefully when comparing the efficiency of fan systems. Because:

qV*pstat<qV*(pstat+pdyn)

Therefore also

ηstat<ηtot

Therefore, different fan systems have to be made comparable before you can realistically compare their energy values. First of all, as described above, this involves how the fans are composed and the definition of the pressures used in the calculation. Instead of talking about percentages of efficiency, it is better to compare fans for a defined air conveying task using the expected power consumption. It is also important to evaluate how the fan will react with its surroundings when installed. These variables, called installation losses (system effects), can become rather important for different fan types and installation conditions, and must be added to the required (static) overall pressure increase when selecting the fan.

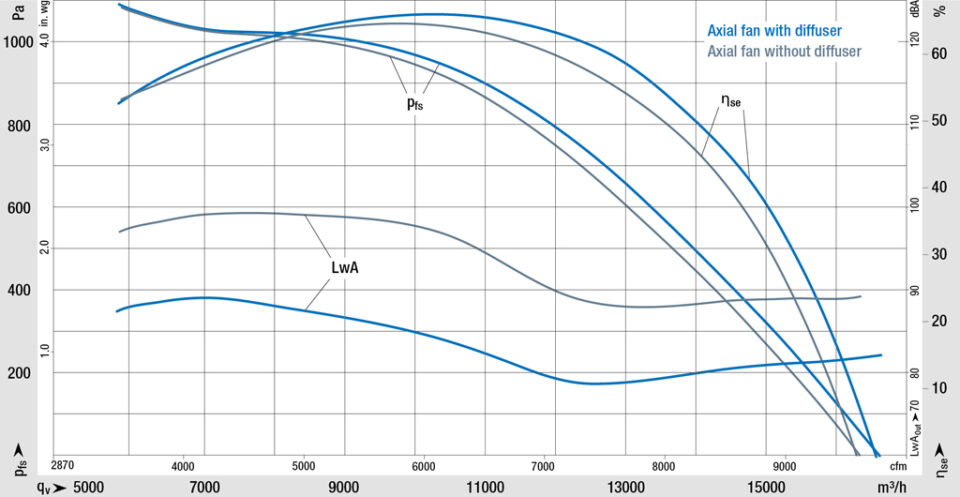

Fig. 3: The figure shows an axial fan’s characteristic curve with and without a diffuser. (Graph | ebm-papst)

Here, axial fans perform much worse with a very high partial speed level than centrifugal fans without a scroll housing. Measurements by ebm-papst have shown that even the best axial fans on the market do not achieve the overall efficiency levels or the low noise levels of centrifugal fans (Fig. 3). However, the efficiency and acoustics of axial fans can be significantly improved using combinations of sound absorbers, diffusers or guide blades mounted on the outlet side. Yet, even with these measures, which significantly increase the overall length, you are best off with a common centrifugal fan.

Centrifugal fans with modern EC technology

The power consumption values specified in technical documents are important when selecting fans. You also need to correctly interpret the specified efficiency levels. With axial fans, you also need to consider the fact that the aerodynamically instable operating range (stall area) is very close to the fan’s optimum efficiency. If the system curve changes to higher pressures, this can have a devastating effect on the device’s operating safety and, therefore, on the entire system.

Leave a comment