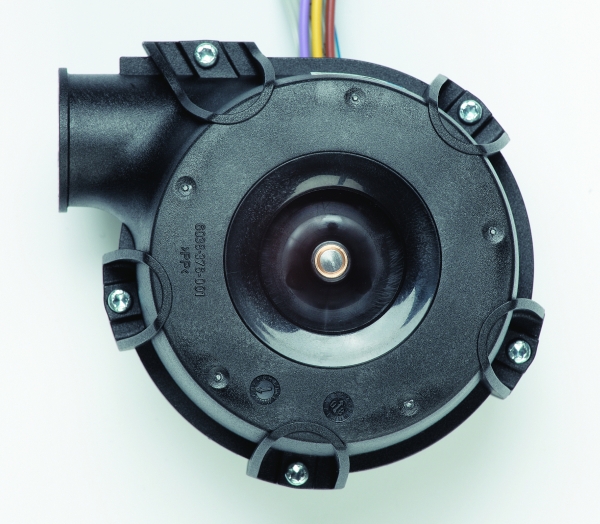

The housing is what gave the Turtle Blower its nickname. The small black plastic case with the five screw bosses and the blower outlet are reminiscent of a small turtle. The task that the apparent reptile fulfils is revealed by its product designation: CPAP centrifugal blower ECI 30.20. The compact blower was developed for medical respiration aids. It supports patients suffering from irregular breathing by ensuring that they have sufficient air supply. As the device is used right next to the patient’s bed, the little turtle has to be mainly capable of two things. Firstly, it has to be very quiet, and secondly it has to respond dynamically and positively to the patient’s respiration requirements. But it can do a lot more than just that.

Staying power

Ten years ago, engineers at ebm-papst in St. Georgen recognised that their expertise in air technology and drive engineering was predestined for use in developing blowers for helping sleep apnoea patients. The early devices were bulky and heavy. That changed in 2003 when the Swedish respiration device specialist Breas decided that it wanted to market a more user-friendly model, following the trend in medical technology of offering more compact devices that were not restricted to a specific point of use. Work started on the measuring rigs and in the development laboratories at St. Georgen: “The market for CPAP blowers was born in our laboratories in 1999, but the starting shot for the Turtle Blower was the joint project with Breas in 2003,” explains Product Manager Claudius Klose. “The ECI 30.20 drive that was developed then was the original model for the drive in the Turtle Blower.” The engineers converted the motor previously used from an external to an internal rotor motor, making a huge step in miniaturization possible. “The Turtle Blower is four times smaller than its predecessor, yet it has a greater power range and weights just half a pound,” summarises Klose. For use in CPAP respiration devices, the blower has to satisfy specific requirements. It supports the body’s respiratory reflexes with a controlled supply of air. Its air flow and pressure must be continually adapted to the patient’s own breathing. The blower drive must therefore be able to adjust its speed with extreme flexibility. The development engineers at St. Georgen designed the blower to be suitably dynamic for a maximum operating point at which a pressure variation of four to 20 millibars is possible within the space of 200 milliseconds.

Quiet, robust and inexpensive

Yet, nobody is awoken by a howling motor. The Turtle Blower’s noise level of 40 dB(A) acoustic pressure makes it rather a quiet companion. This is also the result of its smooth-running design, which generates extremely low levels of vibration. In respiration devices, the blower is given additional damping and is encased in a foam cage within a soundproof box. The air intake and outlet ducts meander like an exhaust system for optimum noise minimisation. The result is that the Breas iSleep device, for example, has a noise level of just 21 d B ( A ) acoustic power – perfect for a good night’s sleep.

The engineers at St. Georgen achieved the smoothness with which the blower runs by using an iron-free motor. Air coils are used instead of stator teeth. This means that the motor has no magnetic resistance, generates less structure-borne noise and has lower power loss. Because the EC technology employed has no brushes (wearing parts), the blower lives up to its nickname in terms of service life: around 20,000 hours, well over two years in “around-the-clock” operation – even in unfavourable conditions. “Dust particles hardly affect the blower. In principle it works like a vacuum cleaner,” explains the Product Manager, stressing the robustness of the centrifugal blower. The EC motor’s hallmark energy efficiency means not only low current consumption. In the case of the Turtle Blower it means above all else improved dynamics. The fact that it is highly competitive is the result of these numerous technical advantages, but also the result of its cost-effectiveness. Its relatively low production costs also makes it economical for the customer.

One for all

While the core area of application of the Turtle Blower today is in respiration devices, its secret has not gone unnoticed in other industries: high pressure and low flow rate. The ideal working level for the CPAP application is also very interesting for other applications.

For example, the standard versions of the blower can also be found in hot air soldering devices and in smoke extraction systems. Take the TITANUS® product family of the company Wagner Group GmbH, the pioneering and globally leading supplier of innovative complete solutions in fire protection. Here, the standard Turtle Blower ensures that air is constantly extracted from the monitored area and conveyed to the detector unit via a pipe system that may be up to 560 metres long. The continual suction power required for this sensitive task is reliably provided by the high pressure of the blower. Because the blower is extremely robust, this smoke detector system is especially well suited for problem areas where there is a high incidence of dust or even radiation. The system is practically noiseless, as the detector in which the quiet turtle works is located outside the monitored rooms. Therefore this system is well suited to detect smoke early, for example in hospital wards or in hotel rooms.

A new orientation

A new orientation

The company Truma Gerätetechnik GmbH & Co. KG in Putzbrunn near Munich was also alerted to the high-performance Turtle Blower. The market leader in the field of liquid gas heating systems for leisure vehicles and boats has developed a fuel cell that can be operated with a conventional propane gas bottle. Because the cell uses hydrogen as fuel, the propane gas first has to be converted in a so-called reformer. The portable VeGa fuel cell system simultaneously employs the blower for two different tasks.

In the reformer, the Turtle Blower supplies the catalytic burners which provide the required temperature for the reforming process. In the fuel cell, the blower conveys the oxygen from the ambient air to the cathode, also under high pressure. The Turtle Blower performs both tasks controlled by valves. Although the standard CPAP centrifugal blower already generates a high pressure with 20 millibars, the engineers at St. Georgen had to modify the coils of the drive motor for Truma, as a higher operating point was needed. The blower now generates an operating pressure of up to 45 millibars in this application. And that is not the only thing that makes it a truly powerful universal genius.

CPAP centrifugal blower ECI 30.20:

- Diameter: 68.5 mm small

- Weight: 250 g light

- Noise level: 40 dB(A) quiet

- Service life: 20,000 hours long

- Performance: 4 to 20 mbar in 200 msec fast

The universal genius generates adequate pressure for these applications:

Sleep apnoea

Sleep apnoea

In this illness, apnoea occurs while the patient is sleeping. The body then suffers from lack of oxygen and generates arousal reactions. These are not noticed by the patient. The consequence of the restless sleep is great daytime fatigue and sometimes severe secondary illnesses such as heart attacks, strokes and depression.

Continuous Positive Airway Pressure is a form of medical respiration employed in both clinical and domestic applications that dynamically supports weak breathing by the patient. It guarantees sufficient respiration volume by continuously monitoring the respiration flow demanded and supplementing this as necessary. Breathing depth, frequency and air throughput are determined by the patient himself. CPAP is primarily used for treating sleep apnoea.

Fuel cells

Fuel cells

Fuel cells convert energy stored in chemical substances directly into electrical current. This contrasts with combustion engines, in which the chemical energy is first converted into thermal energy. The fuel cell has a greater potential efficiency and when operated with hydrogen is also emissions-free, as water is the only waste product created from the reaction.

Reformer

Most fuel cells work using hydrogen. This may be industrially manufactured, supplied in a tank, or it may be generated locally by reformation of a primary raw material such as propane gas. Here, the raw material is converted into a hydrogen-rich gas in a catalytic converter under high temperatures.

Smoke extraction systems

Smoke extraction systems

This active system for fire detection continually takes samples of air from the monitored rooms and conveys these through a pipe system to a detector unit. There, optical measuring chambers analyse the proportion of smoke particles. Physical filters and a fire pattern detection algorithm stored in the software provide a high level of protection against false alarms. In contrast to decentralized fire detectors, smoke extraction systems are more maintenance-friendly and can also be installed almost invisibly.

Hot air soldering

In contrast to soldering with irons, the soldering joints are not heated by direct contact with the hot tool. rather it is heated by a flow of hot air to a temperature greater than its melting point.

Where do I get this turtle blower for my CPAP project?

Dear Neil Gaede,

You can get this blower via our subsidiary in the US (you are from the USA – correct?).

Or you can contact directly ebm-papst in St.Georgen, Germany.

Thanks for your comment!

Best regards,

Your mag°-Team

Hello Team,

Where Can i get the Blower technical specification data sheet ?

Regards

Umesh

Dear Umesh,

Thank you for your interest. I’ve forwarded your request and they will get back to you soon.

Best regards,

Your mag° Team

Hi

How can I receive the blower specification, blower sample and driver? We have several new equipment designs in development

Thank you

MK

Dear Mike,

Thank you for your interest. I’ve forwarded your request and they will get back to you soon.

Best regards,

Your mag° Team

Dears,

Would you send me more details about the blower and its driver?

Thank you.

Dear Mustafa,

Thank you for your interest. I have forwarded your email to our sales team, they will contact you directly.

Your mag°Team

Dear Sir, Madam, are you still making these blowers? I have a respirator project and would be interested in this unit or an equivalent. Many thanks,

David

Dear David,

Thank you for your request which I have forwarded to my colleagues in sales, they will contact you.

In the meantime, maybe this new product might be of interest for you: http://ebmpapst.com/rv45

Best regards, Katrin