Choosing the best fan solution for a particular application is crucial to the performance and efficiency of the system as a whole. If the fan selected is not powerful enough it will not provide the required volume of air. If it is over-dimensioned, the fan will use an unnecessary amount of energy. The FanScout from ebm-papst helps planners and users find just the right fan for the specific application involved.

Figure 1: The FanScout selection program from ebm-papst enables the most economical fan combination to be identified, including FanGrids.

Choosing the wrong fan for a computing center can prove to be a costly business, as cooling accounts for around 37 per cent of the energy costs in such cases. It is therefore imperative to ensure that fans operated in parallel, so-called FanGrids, are of optimum design (Fig. 1, page 6). The parallel operation of multiple small fans has huge advantages over large individual fans in ventilation technology. The more uniform flow through the heat exchangers or filters leads to better heat transfer performance and more efficient filtering of the air (Fig. 2). In addition, several small fans require much less space, which reduces the costs of the system.

Real measured values as a basis

Figure 2: Air flow through a heat exchanger with a FanGrid solution (top) and an individual fan solution (bottom). The latter exhibits non-uniform flow through the heat exchanger and thus poorer heat transfer values.

To avoid the negative consequences of using inappropriate products, ebm-papst has created reliable fan selection software known as the ebm-papst FanScout. This provides air conditioning and ventilation system planners and manufacturers with a quick and easy means of finding the ideal product for a particular application. The software takes up to five different operating points into consideration and works with real measured values. The discrepancy between the calculated operating data and the actual measured data is so slight that the TÜV SÜD certification body has confirmed the top accuracy rating of the software. This means users receive absolutely reliable and above all extremely precise data. The program does not simply measure the performance of the individual fan components, but rather assesses the fan system as a whole, made up of the fan impeller, EC drive motor and integrated control electronics, based on the “Wire-to-Air” principle (from electrical hookup to the available air performance).

High-precision selection procedure

The selection process outlined below shows just how easy it is to design a FanGrid, for example, using the FanScout. Following initial consultations, ebm-papst first narrows down the number of potentially suitable fans and produces a so-called FanScout collection. Users can already pick out fans at this stage with the help of the actual software. Up to five different operating points can be entered. The operating times at each of these operating points viewed over the course of the year yield the usage profile which then serves as a basis for calculation. This method provides a reliable indication of the annual energy consumption and thus of the expected operating costs. Such an approach is far more accurate than the commonly employed method of performing calculation on the basis of the rarely attained maximum operating point.

Redundancy provides operational reliability

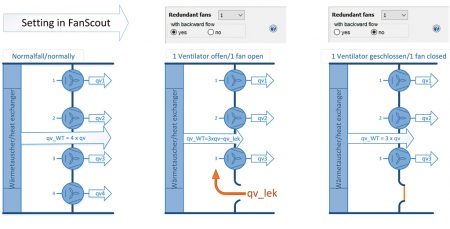

Figure 3: Three FanGrid operating situations: Normal operation with all fans, redundant operation (here n+1) with backward flow and redundant operation (here n+1) without backward flow.

FanGrids for air handling systems are designed with some level of redundancy to guarantee the required air can be delivered to the building at all times.This parameter specifies how many fans can be switched off without dropping below the required air flow. Two important aspects have to be considered. Firstly, the reserve capacity of the remaining fans must be sufficient to make up the amount of air not being supplied by the non-functioning fans. Secondly, it must also be possible to provide compensation for the amount of air flowing back through the stationary fans. A distinction is made between the version with a back-flow flap, in other words with no backward flow, and the version without a back-flow flap. This is also presented in the FanScout (Fig. 3).

The space available for installation can also be specified. This option is particularly useful in cases where the installation space for the fans is extremely restricted, as the function takes into account the pressure losses which arise if fans are fitted too close to walls or other fans. A further option then makes it possible to narrow down the fan type required and the total number of fans to be fitted.

Detailed information on possible options

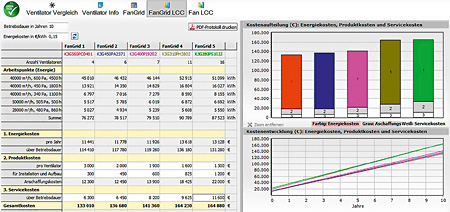

Figure 4: The results list provides an overview of various FanGrid combinations and their energy consumption.

The FanScout calculates various possible FanGrid combinations on the basis of the parameters entered and lists them according to their energy efficiency (Fig. 4, page 7). In addition to energy consumption, the results table provides information on the recommended fan type, the number of fans operating in parallel and the speed factor. This factor indicates the difference between the operating speed of the selected fans and the nominal speed of the fans and is thus a measure of the “reserve capacity” of the chosen alternative.

Figure 5: The sound power of the individual fans can be shown for either the intake or the outlet side.

Air performance, power consumption and efficiency are presented in map form for each fan combination. The specified operating points are also entered in the maps and the operating time share of each is indicated by the size of the points. In addition, the FanScout provides information on noise for the possible fan combinations (Fig. 5). It shows the sound power of a fan – either on the intake or the outlet side – for each operating point. This feature is particularly useful if a FanGrid is to be used in noise-sensitive environments such as offices or residential areas.

Lifecycle costs in focus

To add further weight to the assessment of the various options for the user, the FanScout offers a function for determining the lifecycle costs of the combination under consideration (Fig. 6).

Figure 6: Calculation of the lifecycle costs provides a solid foundation for investment decisions.

This involves multiplying the power consumption of the fans at the respective operating points by the operating time and the electricity costs and adding up the total. The result represents the pure operating costs of the installation over a specified period. If the costs for purchase, installation and service are also entered, the overall costs of the FanGrid over time will be displayed. This provides the user with a realistic cost assessment and forms a reliable basis for investment decisions.

Muy interesante.