Modern buildings require less and less heating energy. For more efficient operation and depending on the building size, heating systems can be designed smaller than ever before. When outdoor temperatures change or extra service water requires heating, higher power is temporarily necessary. In these cases, gas heating system deliver fast energy input with few environmental consequences. To ensure ideal combustion with top consumption and contaminant values in all possible scenarios, a gas blower with as wide a power range as possible is the best solution. Power modulation allows boiler manufacturers to cover a broad application spectrum with only one blower model. And end users have greater comfort because a more efficient device whose high modulation level delivers lower heating and cooling losses covers their higher performance requirements. Both save time and money, reducing their carbon footprints for building heating.

Figure 1: The new VG 100 gas blower functions with a modulation of over 1:10 in the 3-50 kW range.

Today, heating systems must adapt to the available space in buildings. Especially in the smaller power range, end users are no longer willing to devote an entire room to the heating system. Condensing hot water heater and gas boiler manufacturers have responded to customer needs with models that provide high comfort with minimum dimensions – and are environmentally friendly as well. Individual variety has only one disadvantage: the gas blower requirements. Manufacturers either rely on a wide spectrum of gas blowers to cover the heating power range – one for each of the many hot water heater concepts – or forgo the opportunity for hot water heater optimization and make do with one or two gas blowers. With a new gas blower that can adapt to a wide range of installation scenarios and heating outputs more easily, hot water heater manufacturers can cut costs significantly.

Variable, compact design

As an environmentally friendly fuel variant that does not require space for its fuel supply, natural gas is in demand the world over. To adjust to the multi-faceted requirements of today’s modern buildings, ebm-papst Landshut is offering a newly developed premix gas blower for instantaneous water heaters. The VG 100 blower is the first of a new blower generation. It covers a power range of 1.5-150 kW (Fig. 1). It functions with a modulation of more than 1:10 in the 3-50 kW range and in comparison to the previous model, has other benefits such as around 5% more efficiency. This gas blower is predestined for use in modern, efficient warmth generation.

Figure 2: The modular system makes it easier to realize customer-specific solutions on the housing side.

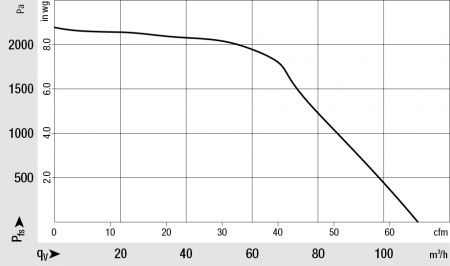

The new blower’s side part is made from sheet instead of the usual die cast aluminum. The new solution enables optimal plug positioning according to the customers’ requirements. The venturi element and side part are separate in order to easily realize customer-specific solutions on the building side (Fig. 2). And the aerodynamics were improved in the process, resulting in a more compact blower that provides significantly more options for integration into instantaneous water heaters. Despite its smaller dimensions, the new blower achieves a higher delivery rate than its predecessor (Fig. 3).

Compact, high performance motor

Figure 3: Aerodynamic and motor-related optimization improve the delivery rate despite compact dimensions.

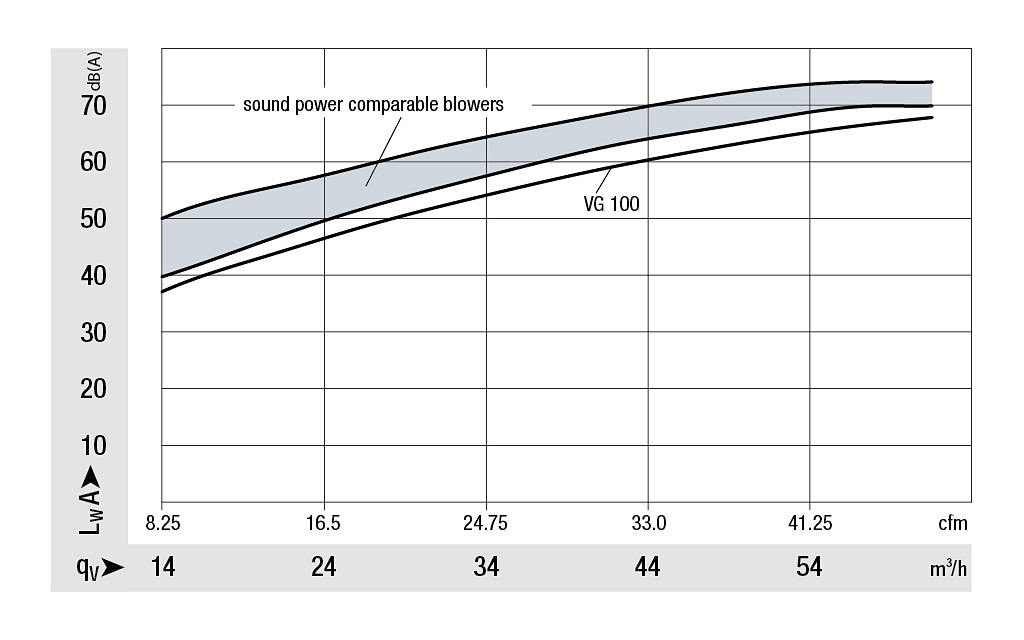

At the same time, a new motor has been developed for the blower platform. The development improves efficiency and reduces the amount of material used at the same time. The motor with zero maintenance ball bearings provides increased power for air delivery adapted to the higher power range – packed into more compact dimensions. New solenoid material and improved stator geometry also make their contributions to performance. Another focus of the development work was noise reduction. In addition to reducing the airborne sound, the developers focused on reducing the vibrations (structure-borne sound) using state-of-the-art development tools.

Figure 4: Noise output is significantly lower than in comparable blowers. This saves extra noise insulation in the hot water heater.

They optimized isolation from vibration and improved the motor’s reaction to vibration in general. As a result, the new blower’s sound power is significantly lower than that of its predecessor (Fig. 4). End consumers are now even more likely to respond positively to a gas-condensing heating system. The electronics were also completely revised and the blower has optional bus interfaces for easy integration into digital systems. In this way, operating states such as power, service state, temperatures, operating voltage and other data that are saved in the blower’s control system can be opened to enable preventive maintenance or (remote) troubleshooting and integration into the hot water heater controls. The new version requires much less (PCB) material. By using the cooling concept proven in other products, the electronics are located in the cooling airflow to increase the blower’s service life and reliability. A motor protection cap connected to the housing encloses all drive components. The stable motor cover design decouples the blower from the motor for lower noise levels and can withstand any rough handling in the downstream assembly process.

Conclusion

As the first representative of a new generation of efficient gas blowers, VG 100 features high modulation rates and extremely compact dimensions. It reduces gas blower variance. With significantly improved efficiency and reduced noise emission, the gas blower is the answer to the requirements of today’s gas-condensing technology market in the power range of up to 50 kW.

Leave a comment