For many hotel owners, air-conditioning systems are often a necessary evil: while they may ensure optimum room temperature, they also use a lot of energy and their noise can prevent guests from getting a peaceful night’s sleep. In hotels for example, the average operating time of fan coils is currently around 80 %, compared to around 40 % in office buildings. The Abasto Hotel in Gernlinden, near Munich, has got to the root of the problem and now uses a new generation of fan coils – to the satisfaction of all parties concerned. Thanks to the highly efficient GreenTech EC fans, rooms can be cooled blissfully quietly to the guest’s preferred temperature using 70 % less energy.

The Abasto Hotel opened in mid-september 2012 around 30 km from Munich, in the district of Gernlinden (figure 1). The 31 modern rooms have been fitted out to the latest standards, and that includes the air-conditioning. for the hotel’s owner, robert rentzsch, who is himself a trained heating installer, the new system fully realises his vision for perfect air-conditioning.

Lower noise and energy consumption with increased comfort

Figure 2: GreenTech EC blowers from ebm-papst in a fan coil unit from Kampmann – invisible to the guest but indispensable for the air-conditioning system.

Both the guest rooms and the “farmhaus” restaurant in the basement are equipped with the latest air-conditioning technology from Kampmann GmbH, based in the German town of Lingen (Ems). Fan coils known as “Venkons” are hidden behind the ventilation slits (figure 2, page 6). The hotel guests cannot see them but they can certainly feel their effects. When the guest checks in at reception, the booking software transmits the starting signal to the Venkon.

By the time the guest goes to unlock the door, the room will have been cooled or heated to room temperature (21 degrees Celsius). If the guest wants the room to be warmer or cooler, they can amend the temperature up to three degrees in either direction via the Ka-Control control device. The unit does not make any noise. Describing an experience that nearly every hotel guest will be familiar with, Rentzsch recalls “I have been in many hotels where the air-conditioning got on my nerves. When you actually have a unit in the room that both heats and cools and is practically inaudible it really makes your stay much more comfortable.”

Figure 3a: The K3G146 energy-saving EC centrifugal blower from ebm-papst ensures a pleasant room temperature while remaining blissfully quiet.

In order to make this feeling of comfort the standard in noise-sensitive applications, Kampmann has developed a system design for its fan coils specially for applications in hotels. In order to fulfil the tough requirements for low noise, the air-conditioning specialist has sought cooperation with its chosen high-performance partner ebm-papst. At the heart of the Venkon is a centrifugal blower, and this is produced by fan manufacturer ebm-papst based in Mulfingen, Germany (Figure 3a).

When Kampmann developed the latest generation of the Venkon, the key factors it looked at were space requirements, noise level and power consumption. ulrich Budde, sales Manager for Kampmann in southern Germany and Austria explains that “The crucial factors for us with the fan coil was that the motors would have a particularly low noise level and that there would be a high level of control in the lower speed range.” Both factors are inextricably linked; hotel air-conditioning systems employ the lower speed range because it offers the lowest noise levels.

Continuously adjustable – for greater satisfaction

Figure 3b: RadiPac centrifugal fans such as the r3G355 used in the Airblock C, with aluminium-welded impeller and energy-saving EC technology have an especially space-saving construction as compared with belt-driven motors.

The lower speed range is also the range with the greatest potential for energy savings. Standard AC motors only offer incremental control, whereas modern GreenTech EC motors are continuously adjustable across the entire speed range. Even at low speeds, the high level of energy efficiency of the EC motors brings benefits, as the motors are supplied with an input of 0-10 V.

The GreenTech EC centrifugal fans are available as single, dual or triple fans with a power of between 40 and 250 W, to suit the room size. In all sizes, they offer energy savings of up to 70 % and noise reduction of up to 5 dB(A). Thanks to the plug-and-play solution, existing units can also be retrofitted without a great deal of work (figure 4).

ebm-papst’s product range includes EC fans in the power range 400 W – 12 kW for ventilation and air-conditioning technology (VACT). The RadiPac range (Figure 3b) with aluminium-welded impellers and integrated control electronics enable a design that saves on space compared to models with belt-driven motors.

The resulting space saving also facilitates installation and start-up. The intelligent control electronics of the GreenTech EC centrifugal fans enable a number of different automation and management tasks to be implemented via MODBus. Major savings can be made on the electrical operating costs thanks to the ability to control the GreenTech EC centrifugal fans based on actual requirements.

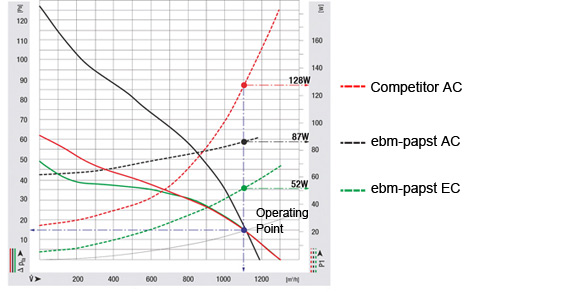

Figure 4: At the example operating point of 1100 m³/h, the green characteristic curve shows the clear energy saving of up to 60 % made by the K3G146 GreenTech EC blower (52 W power consumption) in comparison to standard AC centrifugal fans (black characteristic curve: 87 W power consumption, red characteristic curve: 128 W power consumption).

Benefits of a decentralised system

The hotel’s owner, Robert Rentzsch, explains that “for me, the energy-efficient EC motors were a crucial determining factor, because i had designed the entire building with a view to keeping the operating costs as low as possible.” The hotel owner has installed 40 Venkons in the Abasto Hotel: 31 in the guest rooms and nine in the restaurant. Heat is provided via a heat pump with 45 °C flow temperature, and cooling is provided using ground water. The highlight of the system is that heating and cooling takes place actually inside the room itself; the ventilation unit under the roof merely provides fresh air and recovers 81 % of the heat from the air extracted from the room.

Figure 5: in ventilation and air-conditioning systems such as this Airblock C system from Kampmann, r3G355 fans with GreenTech EC technology from ebm-papst reliably supply fresh air.

Standard centralised units heat and cool the air centrally and then distribute the air around the building via air ducts. The Air-block C ventilation unit (figure 5) manufactured by Kampmann using GreenTech EC fans now only supplies the fresh air – the decentralised Venkons inside the hotel rooms are operated individually. The unit is therefore very compact and the supply air ducts can also be made smaller. As a result, transport losses are also greatly reduced.

For Robert Rentzsch, the factor of whether a system is decentralised or not is in itself no insignificant matter: “For heating installers, space is always a major issue.” This is because entralised systems necessitate ducts with large cross-sectional areas. Rentzsch has managed to install the system with just 30 centimetres of intermediate ceiling at the Abasto Hotel. With a centralised system he would have required up to 80 centimetres – dead space that would only have increased costs. “I was convinced straight away that we should be heating and cooling the air where it is actually going to be used”, says Rentzsch.

The operating costs at a glance

“I believe that the concept we have here is the best possible solution for hotel applications”, claims Ulrich Budde with conviction. He is also pleased about the increased level of controllability. If the air quality is OK, the system simply provides heat or cooling as required; if the temperature is OK, the system simply provides ventilation. However, it is not always easy to communicate the best solution. Although at Abasto Hotel the investor is also the user, and therefore close attention was paid to the operating costs. “As a general rule, investors look above all at the investment costs and the minimum legal equirements”, says Budde, explaining the market situation. A key factor is the life cycle costs over the

entire service life.

The minimum requirements are also becoming more stringent: the European union’s Energy-related Products Directive demands a much higher level of energy efficiency. Air-conditioning devices with GreenTech EC technology help with compliance as they already go significantly beyond the requirements. What is more, buildings equipped with high-quality technology with a long service life fare much better on the real estate market. Finally, guests are much happier when they can stay in a hotel room with blissfully quiet air-conditioning technology; they will be more likely to come back for another stay and will spread the word.

Conclusion

The successful use of GreenTech EC technology in this hotel application clearly illustrates just how much this technology has to offer hotel owners in comparison to a standard air-conditioning system with AC motor and incrementally controlled winding. Firstly they benefit from the reduction in noise thanks to the EC motor, which is up to five decibels quieter – for the human ear this equates to a reduction in the overall noise impression of almost half. Secondly, they can reduce energy consumption by up to 70 % thanks to the high-performance, continuously adjustable control functionality across the entire range. Hotel owners save on energy costs, architects and building planners benefit from a future-proof solution and guests can finally have a more peaceful night’s sleep.

Kampmann GmbH

This company headquartered in the town of Lingen an der Ems in the region of lower saxony (Germany) develops, produces and sells systems for heating, cooling and ventilation, always employing state-of-the-art technology for its products. The technology leader employs around 700 employees in 15 branches. The collaboration with the fan manufacturer ebm-papst has been going strong for more than 30 years.

Hotel Abasto

The hotel to the west of Munich was opened in September 2012 and offers 31 rooms for guests as well as its “Farmhaus” restaurant.

www.abasto-hotel.de

Leave a comment