Phillipp and Lennart Momeyer don’t know the exact year their family started farming. It was a long time ago. “Far before our time,” they laugh. Now in the third generation, the Momeyers run a pig farm here in the Lüneburg Heath, with space to feed approximately 3,000 pigs. Business is going well but the family saw that there was potential for improvement in the operation of the barn.

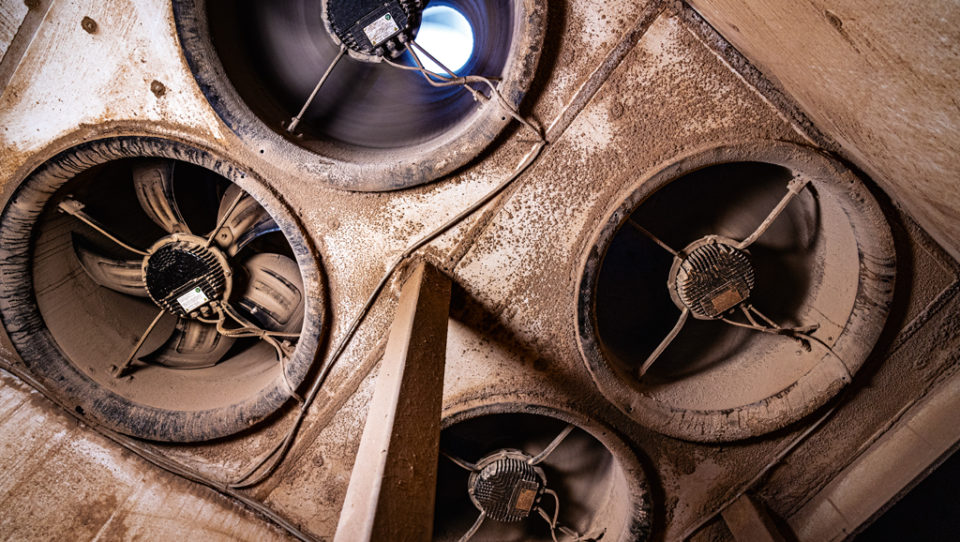

“We have been documenting our electricity consumption for three years now,” explains Phillipp Momeyer. “Here we discovered that the energy costs of our ventilation were simply too high.” When it came to the ventilation, Momeyer was relying on four axial fans, running continuously with switch-on and switch-off functionality. “We wanted to change over to EC technology because it saves energy and can be controlled better.”

In agriculture, the requirements are strict when it comes to outgoing stale air from the barn. Here one thing counts above all: speed. “With the new ventilation system, it was important that we still complied with our minimum stale air speed for the necessary approvals,” explains Momeyer. To implement this technically, the brothers looked for an expert partner. This they found in Heinrich Dönselmann-Theile. The qualified electrician runs the company HDT Anlagenbau in Diepholz. “Many electricians think that all it takes to sort the climate in the barn is to order a controller,” says Heinrich Dönselmann-Theile. “But it involves more.”

Agricultural expertise

Dönselmann-Theile has gained a lot of experience over the years. Now in the second generation together with his sons, he focuses on the topic of barn climate. With his employees, he creates tailored solutions for his customers and builds systems which are state of the art. “At the Momeyer’s, we divided the fans into three groups, each with four fans: two groups for the outgoing stale air and one for the air supply. The four size 900 models for the air supply are also located in a heat exchanger which heats the air supplied, ensuring that the animals don’t get cold in the winter from the ventilation.”

Another key feature of the system is that in order to save energy, the fans only run at 80 percent power. It is only during extreme weather, for example when it is over 38 degrees outside, that the software activates the remaining 20 percent. “We were only able to adapt the software in this way because the characteristics of the fans are perfect for it,” says Dönselmann-Theile.

Reservations against EC technology

Aggressive barn air is not only a problem for animals, but also attacks devices such as fans. In agriculture, there are reservations against EC fans because their electronics are installed on the devices themselves. Skeptics fear that the fans will then break quickly because of this — but this is not the case with the Momeyers. They trust HDT and HDT trusts ebm-papst. “When it comes to the seals and robustness of the fans, we don’t have any concerns at all,” says Phillipp Momeyer.

Wolf-Jürgen Weber, Regional Head of Sales at ebm-papst, explains: “In comparison to competitors’ products, our fans cope better with the challenges arising from use in a barn. In order to make our products more corrosion resistant, for example, we use certain coatings and take further special measures to protect the fans against corrosion.”

“When it comes to the seals and robustness of the fans, we don’t have any concerns at all.”

Phillipp Momeyer

Retrofit saves money

The results of the retrofit to the ventilation system have exceeded everyone’s expectations. “We originally anticipated cost savings of around 35 percent. After six months, we are already at savings of over 50 percent,” says Phillipp Momeyer, who meticulously recorded the power consumption. “We would never have expected such savings ourselves,” says barn climate expert Dönselmann-Theile. “But it shows that we are on the right path with our control strategy and the EC fans from ebm-papst.”

Sources: Landwirtschaftskammer Österreich, agrar heute, Destatis, Zeit Online

Leave a comment