Nowadays, data centers are springing up wherever you look. So much waste heat is generated in each of these data centers that around half of the required electrical energy must be used for cooling the hardware alone. Yet the information age has only just “warmed up”; the larger the volume of data is, the higher the required cooling capacity and thus the energy consumption will also be. These facts are accompanied by the desire for higher computational capacity over the same floor space, which results in the fans needing to move more air without increasing in diameter. In today’s precision air-conditioning units, for example, air-duct cross-sections are designed for larger quantities of air, which improves cooling and minimizes flow losses.

Optimized for new requirements

Figure 2: A CRAC unit with a diagonal heat exchanger: The blue areas represent low-speed air flows, while the red areas accordingly represent high-speed air flows.

Precision air-conditioning units are usually deployed in data centers. These units – also referred to as Computer-Room Air-Conditioning (CRAC) units – guarantee a constant temperature and humidity in data centers and network control centers. CRAC units with heat exchangers are used in this case (Fig. 2). The design of the CRAC units significantly influences the choice of suitable fans. In light of the considerably lower back-pressure requirements, these are now also required to work at the optimum operating point to ensure that they can run energy-efficiently and save on operating costs. After all, every watt counts during round-the-clock operation in data centers. To this end, motor and fan specialist ebm-papst Mulfingen has expanded the tried-and-tested RadiCal model series (Fig. 3).

In order to tailor the operating point of the RadiCal fans to the higher air flow desired by the market, the aerodynamics of the impeller were overhauled.

In order to tailor the operating point of the RadiCal fans to the higher air flow desired by the market, the aerodynamics of the impeller were overhauled. Powerful simulation tool Computational Fluid Dynamics (CFD) was a great help in doing so: In conjunction with numeric optimization approaches, this resulted in a number of individual detail improvements that make a real difference overall. As such, the width of the impeller, the size of the intake area, the blade contour and blade thickness were all adapted to the higher air flow and lower head. Like its predecessor, the new impeller is made of glass-fiber-reinforced polypropylene. The outer diameter and installation height have remained the same in spite of the optimization. This enables the limited space available in CRAC units to be utilized to best effect.

Figure 3: The new RadiCal has been tailored to the changed market requirements.

A higher air flow with high efficiency

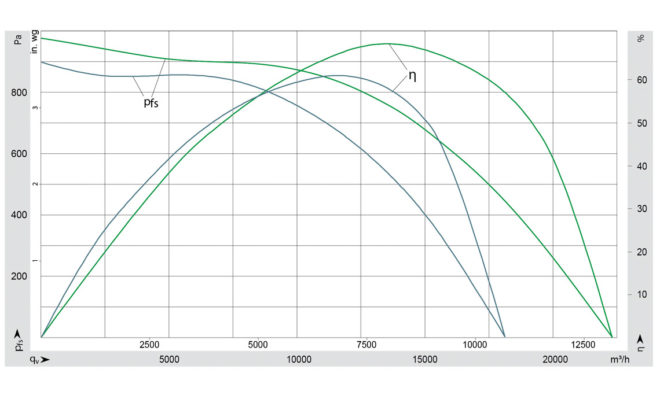

For this particular advanced development, the engineers in Mulfingen set their sights on the aerodynamics, and the results are plain to see: The new RadiCal not only delivers a higher air flow than its predecessor, but also operates more efficiently (Fig. 4). Thanks to the computer-assisted optimization methods used, the new RadiCal impeller is not only considerably better than the predecessor model, but is currently also the best impeller in the world for this application, i.e. for this air performance range and degree of efficiency. Its predecessor achieves its maximum static overall efficiency of 61.5% at an air flow of 12,000 m³/h. The maximum of 68.5% for the RadiCal is achieved at an air flow of 13,000 m³/h. The new RadiCal impeller can lead to efficiency improvements in other applications, too.

The maximum static overall efficiency of 68.5% for the RadiCal is achieved at an air flow of 13,000 m³/h.

The efficiency advantage of the new RadiCal impeller also shows itself in an installed state. In a CRAC unit, three RadiCal fans running in parallel were compared using the previous and new solution. The result was a reduction of more than 10% in the fans’ electrical power consumption. Thanks to lower flow losses in the impeller, lower turbulence and less laminar separation, the fans also have more pleasant noise characteristics.

Figure 4: The new RadiCal (green) not only supplies a higher air flow than its predecessor (blue), but also operates with higher efficiency.

Efficient GreenTech EC technology

The impeller is perfectly tailored to the likewise optimized GreenTech EC motor and is bolted directly onto the motor’s rotor. Due to the aerodynamic shape of the fan impellers and the EC motor integrated into the impeller itself, the centrifugal fans comprise an efficient and space-saving unit (Fig. 5). The power electronics integrated into the GreenTech EC motors enables the speed to be adjusted to meet requirements by means of a 0–10 V control signal or via Modbus RTU. The high level of efficiency is even maintained in partial-load operation.

Figure 5: The width of the impeller, the size of the intake area, the blade angle and blade thickness have all been adapted to the higher air flow.

When using the Modbus RTU interface, numerous operating parameters can also be queried and monitored in ongoing operation alongside the control signals. When needed, the operator can quickly modify operating parameters in order to promptly react to changing requirements. Simultaneously recording operating hours facilitates preventive maintenance for effective minimization of servicing time. Should servicing still be needed, the affected fans are easily identified thanks to the Modbus RTU communication. Fail-safe functionality enables safe operation, even in the event of a bus communication failure; the fans simply continue to run at the currently set speed.

Practical and future-proof

RadiCal centrifugal fans are available for all common line voltages and frequencies. In addition, installation is simple and practical. As such, the installation position of the fans can be varied due to the optional fixing bracket: It is possible to install them with the motor shaft in either a horizontal or vertical orientation. The new RadiCal fans therefore represent a practical and future-proof solution for powerful, energy-efficient CRAC units.

Leave a comment