Mobile internet, cloud computing and ever more industrial networking have led to a massive increase in the volume of data being processed in data centers. Cooling is the key to efficient operation. Energy consumption is the main cost factor – and the cooling system is a crucial aspect. At present it accounts for around 37 per cent of the energy costs on average – and the figure is even higher with older systems.

Energy costs: the key to economical operation

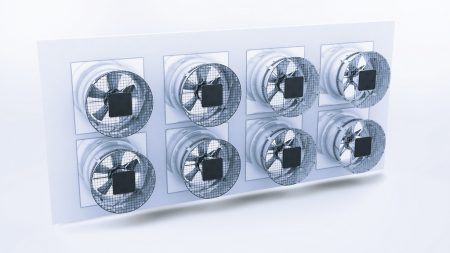

All efforts to cut operating costs therefore hinge on this item. Efficient cooling concepts these days are often based on free cooling and many do not require the use of compression refrigeration systems. Modern installations use the outside air, often in combination with adiabatic cooling (evaporative cooling), to provide appropriate air conditioning for data centers. Such cooling concepts do however require a large volume of air. Use is increasingly being made of so-called FanGrids – a system of centrifugal or axial fans operating in parallel – to satisfy the demand for a higher air performance (Figures 1a and 1b).

Air flow routing

A distinction is made between indirect and direct free cooling systems. Indirect free cooling employs two separate cooling circuits. The cool outside air is not routed directly into the data center but is rather used to cool the circulating air flow in the data center by way of a heat exchanger. By contrast, a direct free cooling system draws in the cold outside air, filters it and routes it directly into the data center. Additional outside air filters are required with this method to ensure air quality and purity. The principle employed ultimately depends on the requirements, location and size of the data center concerned.

Customized FanGrids

ebm-papst helps customers to design an ideal FanGrid with the support of the company’s Product Selector software FanScout (patent pending). The most economical system is worked out on the basis of parameters such as the installation space available, the required operating points and the desired level of redundancy. The software also takes the lifecycle costs into account, in other words the purchase price and operating costs over a defined period.

Figure 2: The blue dots symbolize various operating points. The size of the dot reflects the number of operating hours at this operating point.

In the past, the operating point with the highest air flow (maximum operating point) often formed the basis for FanGrid design. This is however seldom attained – usually only if the data center is operating to full capacity with high outside temperatures in summer. Most of the time a data center cooling system runs at part load. For this reason the design software from ebm-papst allows up to five different operating statuses (operating points) to be specified. The applicable operating time in hours per year is stored for each of these operating statuses. This produces weighted operating points which reflect operation for the year as a whole.

Figure 3: If the annual energy consumption of the FanGrid is calculated on the basis of weighted operating points as opposed to the maximum operating point, the real energy consumption will be 20,000 kWh lower, as shown by the calculation example for a FanGrid with four RadiPac centrifugal fans.

An example is shown in Figure 2. Realistic figures for the expected operating costs can be calculated from these points. For this purpose, the software configures all the possible FanGrid combinations (type, size and number of fans) and works out the most energy-efficient alternative. When viewed over the course of the year it is quite possible that the combination with the greatest efficiency at the maximum operating point does not necessarily produce the best consumption figures on the basis of the weighted operating points.

The weighted operating points enable energy consumption to be calculated far more accurately. By way of example, Figure 3 shows the energy consumption calculation for a FanGrid with four RadiPac fans. The left bar represents energy consumption calculated on the basis of the maximum operating point (approx. 70,000 kWh). The right bar (approx. 50,000 kWh) shows the actual annual energy consumption of the FanGrid calculated using realistically weighted operating points.

All the latest technology

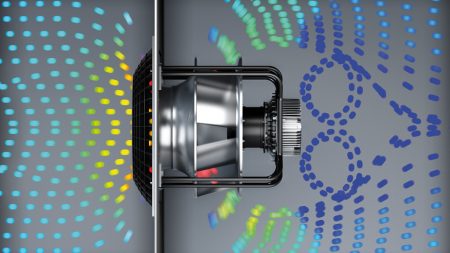

Figure 4: With the new RadiPac, particular attention was paid to the air intake in the impeller, the positioning of the external rotor motor in the impeller and the blade profile of the impellers.

Such savings can be achieved through the use of EC fans in FanGrids. These are highly efficient and can always be regulated to the required operating point. The new RadiPac EC centrifugal fan for ventilation technology has been on the market since October 2015 (Figure 4). These fans are not just 13 per cent more efficient than their predecessors, the noise level has also been cut by more than 3 dB (A). Optimized outflow characteristics ensure the best possible flow control even when there is not much room available (Figure 5, see page 34). The new RadiPac in FanGrids is thus the ideal space-saving solution for efficient operation in data centers.

Figure 5: The new RadiPac EC centrifugal fan is not just 13 per cent more efficient than its predecessor, but also 3 dB (A) quieter. Optimized outflow characteristics ensure the best possible flow control even when there is not much room available.

Installation losses are another factor which tends to be overlooked in practice. If fans are installed too close together, they will influence one another. As a general rule, the greater the volume of air to be conveyed, the further apart the fans should be. ebm-papst’s design software automatically allows for possible installation losses. FanGrids often feature built-in redundancy. If one fan fails, the speed of the others is automatically increased to provide the best possible compensation for the loss of air performance. This does however have the following consequence: On account of the fan failure, some of the air produces so-called backflow. The associated losses depend on the operating point and must be taken into account at the design stage.

To sum up

ebm-papst FanScout: Completely reliable and, above all, precise data as the software is based on true measured values. Not only is the performance of the individual fan components measured but also that of the fan as a complete system – as confirmed by TÜV SÜD.

ebm-papst starts by taking a look at the specific situation, including the installation space available, the operating points and the required level of redundancy, to ensure that the free cooling concept works with an optimum FanGrid design. Bearing in mind the lifecycle costs, the most appropriate system is then defined in terms of the type, size and number of fans to be used. Spacing and arrangement are further important factors when designing FanGrids. As a rule of thumb: The greater the air volume, the larger the space between the fans. Only then will the desired performance and efficiency be obtained.

The Product Selector software FanScout permits the weighting of different operating points. Consequently the system design is not based on the maximum operating point as is often the case, but rather geared to individual customer requirements. In connection with the weighted operating points it is also possible to simulate various operating scenarios such as a constant air flow or constant pressure – making FanGrid design more efficient and cutting operating costs. Offering sophisticated EC technology and a wealth of expertise, ebm-papst can help customers find the optimum solution for their cooling concept.

Leave a comment