In many areas, current technology relies on targeted air cooling. In addition, modern DC axial fans score highly in many ways: they are energy efficient, durable, and do not require maintenance. Depending on the version, they can also be integrated into networks. Yet, one disadvantage of many fans is the unpleasant operating noise. With new fan concepts, noise emissions can be substantially reduced depending on the operating point; fans with low noise, which are also less bothersome, are particularly suitable for applications in areas in which people live and work.

Figure 1: In many areas, technology is advancing ever closer to people. In this regard, quiet-running fans can improve the well-being of the environment. (Photo | fotolia.com/3darcastudio)

Many applications require quiet fans with high flow rates. For example, if decentralized ventilation or a solar inverter is installed in a house, the living environment should not be negatively affected by excess noise (Figure 1). The same applies in automation technology, e.g., in frequency converters (Figure 2). For medical applications, a low noise level in the cooling of electronics is important in order to prevent additional disturbance to patients. In many applications – whether one considers refrigerated display cases in supermarkets, IT & telecommunications with switch cabinets, IT servers, or network equipment – technology is moving ever closer to people. Fans from ebm-papst, which cool the air without unnecessary noise, make a substantial contribution to making everyday technology quieter.

Causes of noise

Figure 2: The number of frequency converters is steadily increasing; quiet cooling improves working conditions. (Photo | fotolia.com/Michael)

In general, fan noise can be caused by one of two mechanisms. The first is noise generated directly by air movement and the associated pressure fluctuation (aeroacoustics). The second is noise resulting from the contact or rubbing of solid bodies (impact sound). In addition to these two main mechanisms, noise may arise from the integrated power and control electronics. When designing fans, aerodynamically generated noise poses a particular challenge. Even the smallest changes in blade design or in the struts or housing can have a considerable effect on the noise level. For example, the air flow on the outer and trailing edges of the blades can be interrupted, and the resulting turbulence increases the generation of noise. The air that flows over the struts, which keep the rotor in the housing, also creates turbulence. Pressure fluctuations also result when a blade sweeps over a strut. Impact sound is the second component that contributes significantly to operating noise: for example, these vibrations of the fan structure may be generated by an imbalance of the rotor or an electric or magnetic impulse in the engine, which is similar to a familiar transformer hum. The structure then acts like a loudspeaker. The vibrations are particularly strong if the resonance frequencies in the fan structure are excited. However, beginning at a certain speed, the noise emission of the fan will be dominated by aeroacoustic effects.

Quiet operation can be developed

Figure 3: The in-house testing laboratory and an air performance test rig facilitate the testing of new developments.

To minimize these aeroacoustic effects, the rotating blades are fashioned in a complex manner. The aim of this process of aerodynamic optimization is to achieve low noise emissions with a high efficiency. One way in which this goal is achieved is by aligning blades and struts with each other (e.g., coordinating the geometries of the back edge of the blade and the front edge of the strut). Through continual improvements, fan specialist ebm-papst has obtained optimal results with its latest fan. This fan design was calculated with the help of specific simulation software and was verified in practice at our in-house testing station (Figure 3). Finely balanced rotors with maintenance-free ball bearings minimize vibration and reduce impact sound. Together with a vibration-optimized structure (designed with modern finite-element methods), the smallest possible impulse is achieved. The design engineers responded to the magnetic and electric excitation with optimized magnetic flux in the stator and rotor of the motor, as well as with optimized electrical connections and select electronic components.

Measures in practice

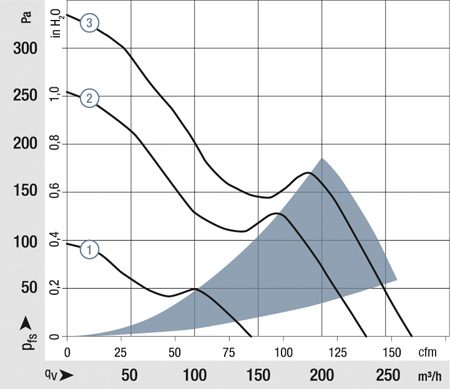

In order to minimize operating noise, the developer must implement a whole series of improvements. For example, let’s take the new S-Panther model (Figure 4). An optimized current and magnetic flux as well as a precisely balanced rotor assembly ensure quiet operation. The aerodynamically designed outer edges of the rotor blades with so-called winglets, which are specially arranged struts (Figure 5), minimize turbulence between the blade and the housing. Together with the newly designed struts, the improvements enable the fan to work 3% more efficiently than its predecessor (Figure 6).

An optimized current and magnetic flux ensure quiet operation.

At ebm-papst, the modern design of fans involves the physical design, the specific drive concept, and control electronics, as well as the selection of materials and the construction of the fan itself. Thanks to injection-molding techniques, plastics allow for a wide variety of designs, that are lightweight, and (depending on the type of plastic used) offer great resistance against corrosion and wear. This is why the 3250J features select plastics that not only ensure a precise contour in injection molding but also provide a high degree of attenuation that is inherent in the material. The housing is made of glass-fiber-reinforced PBT (polybutylene terephthalate), and the impeller is made of glass-fiber-reinforced PA (polyamide). The drive motor is optimally integrated in the impeller, and the stator coils and electronics are also fully cast in plastic. This ensures good protection against water, dust, and salt spray, among other things.

Excellent combination of performance and reduced noise

Although the technical effort involved in designing such a quiet but powerful fan is considerable, it does yield significant advantages in many areas. The 92 × 92 × 38 mm (H × W × D) S-Panther is available for 12, 24, and 48 VDC operating voltage, each with IP68 and IP54 protection (optional). Depending on the variant (7, 24, or 35 W power is available), the fan conveys between 145 and 270 m3/h with an operating noise of only 47 or 63 dB(A). The lifespan is over 85,000 hours (L10, 40 °C) according to the strict in-house test configuration and approximately 150,000 hours according to standard evaluations. Various optional features, such as speed signal output, a go/no-go alarm, or an internal/external temperature sensor are also available, as is PWM control input or analog input. The molded drive and specially sealed bearings provide protection against moisture and salt spray; the high efficiency results in lower electrical energy requirements. Those who value the highest possible air flow rate, and are willing to accept slightly increased noise, will be well served by fans of the S-Force series. Up to 280 m3/h at 73 dB(A) is possible! The pressure increase also improves from 340 up to 700 Pa. This ensures a high air flow rate even with greater air resistance in the unit (e.g., through filters or the compact arrangement of components).

Leave a comment