The true efficiency of a fan when measured is not equal to the product of the maximum individual efficiency levels of the motor, drive unit, control system and impeller. But why is that?

Correct determination

For a retrofit project, enquiries are made about various fans and the performance data of the fans offered are then compared. It is important to remember that performance specifications based on calculations are generally not realistic. They tend to be far too optimistic because the maximum efficiency levels of the individual components (motor, drive unit, control system and fan impeller) are usually taken from catalogues for calculation purposes.

It cannot however be assumed that each component will actually achieve maximum efficiency under realistic conditions. Multiplying the optimum individual efficiency levels yields a far more favourable total efficiency than is possible at the actual operating point (Fig. 1).

As a result of this error, the values obtained from calculation of the power consumption will be far better than in actual operation. To ensure that realistic values are acquired, ISO 12759:2010 “Fans – Efficiency classification for fans” expressly recommends working with measured values when planning.

As good as it gets

ebm-papst can always be relied on to provide the correct values because what we measure and supply is the minimum configuration of a complete, ready-to-install fan assembly consisting of high-performance impeller, EC motor and control electronics. As these components are optimally matched, it is possible to achieve static total efficiency levels well in excess of 60 %.

These levels have been measured and entered in the Product Selector. Far higher figures quoted by other suppliers are always open to question.

In addition to optimum efficiency, a RadiPac with GreenTech EC motor offers a whole range of advantages over other fans for air handling systems.

Installation – simple and safe

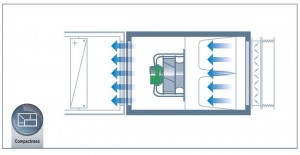

The high-performance impeller is mounted directly on the rotor of the external rotor motor. This saves space and permits balancing of the entire rotating unit in one clamping operation (Fig. 2). The electronics and motor are combined in a single unit (Fig. 3). Thanks to the integrated control electronics there is no need for an external frequency converter, which makes installation easy.

As the motor and electronics in the motor system are perfectly matched and in close proximity to one another, additional electronic filters and shielded cables are also superfluous and no external motor protection circuit breaker is required. Air handling units can be commissioned without the need for any costly adjustment, earthing or shielding work. In other words “Plug & Play” for ventilation technology.

Ecodesign

Minimum efficiency requirements for RadiPac EC centrifugal fans as per the 2015 ecodesign directive

The ecodesign directive for fans (EU 327/2011) specifies minimum efficiency requirements for fans driven by electric motors. The requirements first came into force in 2013 and will become more stringent as of 01.01.2015. They apply to all fans with an input power between 125 W and 500 kW and a drive performance range of 125 W to 500 kW. A specified efficiency level has to be attained based on the type of fan concerned. Calculation of the minimum efficiency values is described in this directive. All GreenTech EC fans in the ebm-papst RadiPac product range now already surpass the requirements applicable as of 2015.

Resource preservation

The GreenTech EC motor helps to preserve resources without any supply risks. The efficiency of the mains-powered permanently excited synchronous motor with electronic commutation (also known as BLDC or PM motor) far surpasses efficiency class IE4 – and manages to do so without using any potentially problematic rare earth magnets.

On account of their design, other permanent magnet motors of the internal rotor type and offering comparable efficiency require rare earth magnets. And so RadiPac is THE compact, efficient, user-friendly, sustainable all-in-one fan solution for air handling units (Fig. 3).

It is impossible to find any documentation about fans on your site (https://mag.ebmpapst.com/en). I have tried to find it here but all I found is tales and sales talk.

Please give me a correct link where I can find technical documentation

Dear Mr Budel,

Thank you for visiting our Website http://www.mag.ebmpapst.com – this is where we publish articles from our magazines.

Technical information on our various products you may find on our regular website http://www.ebmpapst.com. If you’re looking for axial fans, this might be the right Website: http://www.ebmpapst.com/en/products/axial-fans/axial_fans.php

Your mag!-Team