Music fills the background, the appropriately colored lighting softly illuminates the flashy product packaging. The supermarket freezer cabinet hums reliably — after all, the temperature must not exceed minus 18 degrees Celsius. This is how a refrigeration chain must function to deliver on its promise to maintain the food’s quality.

Fresh food is used to produce frozen food. Meat, fish, vegetables and fruit. In order to maintain their quality over a longer period of time, the blast freeze process is used. The food is chilled to below – 18 degrees Celsius in a very short time. In the case of flow freezing, icy air currents with temperatures as low as – 40 degrees Celsius are used.

For refrigeration circuits

Bohn manufactures the components for refrigeration circuits like these for its customers. In Mexico, Bohn is a specialist in the refrigeration technology sector and sells various systems for warehouses and cold-storage rooms, containers and vehicles to food logistics companies. In the process, Bohn is faced with the technical challenge of bringing large rooms down to frost temperature to produce frozen foods. Lots of air has to be chilled quickly.

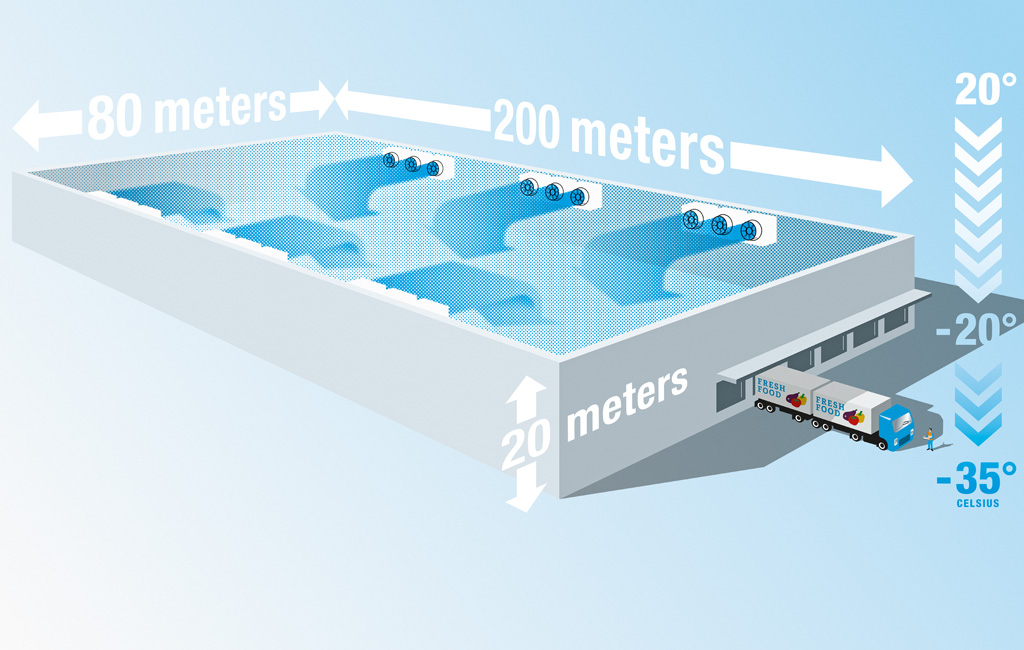

320,000 cubic meters in less than five hours until minus 35 degrees Celsius.

For example, the temperature in a hall measuring 320,000 cubic meters — 200 meters long, 80 meters wide and 20 meters high — must be chilled from + 20 degrees Celsius to – 20 degrees Celsius in less than two hours. The room must be chilled for three more hours until the temperature is – 35 degrees Celsius. Then the room temperature must be maintained. Since 2016, Bohn has equipped its blast freezer evaporators with EC fans from ebm-papst.

Large, efficient and adjustable

The medium pressure axial fan has proven to be the most suitable variant because it is large, efficient, has an extremely high throw and can be controlled. With a diameter of 1,120 mm, it can transport an air volume of up to 50,000 cubic meters per hour at a back pressure of between 200 and 550 Pa.

To move the air in the gigantic warehouse, three evaporators are installed directly under the ceiling on each side of the building. Three fans turn in each evaporator, yielding a total of 18 fans. They are opposite each other in order to reach every corner of the hall and each one has a throw of 40 meters. Temperature sensors control the fan speed in order to keep the temperature stable.

Fresh food packed with vitamins

The food in the supermarket freezer cabinet reveals nothing about this technically sophisticated task and consumers learn about it only indirectly. They can enjoy products full of vitamins, nutrients and aroma.

Leave a comment