The world eats out. More and more people are not cooking at home, but rather eating on the go and preferably at all times of day. When filling up the car, shopping or at a bar after work. The classic restaurant is no longer the first destination, for things have to move fast – and taste great nevertheless.

The food industry has reacted: a broad spectrum of frozen products makes it possible for stores to offer an extensive menu even without a chef. The trend is clearly toward front (“on-stage”) cooking: customers want to see how their food is prepared. This presumes that an appropriate and easy-to-operate device with a pre-programmed baking program is available, because pizza is supposed to be nice and crispy.

The consequence: on the shop counter, where there isn’t much space, kitchen appliances have to be as compact as possible and work as quickly as possible, for preparation shouldn’t take more than a minute or two. The next customer doesn’t want to stand in line for long. Therefore, what’s needed is a lot of power in a small space. Compact high-performance ovens are just the thing here.

Expertise from baking lines

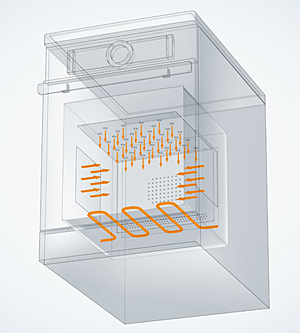

Fig. 1: Efficient combination: compact hot-air-impingement ovens unite convection, radiation, and microwave technology. This keeps preparation times as short as possible.

Manufacturers rely on so-called hot-air-impingement ovens, which combine convection, radiation, and microwave technology. Hot air is blown through nozzles onto the baked goods at high pressure of up to 4,000 Pascal (Figure 1). Temperatures of up to 450 degrees are thus possible and the pizza is nice and crispy in no time at all. Dishes can be prepared up to 15 times faster than with traditional ovens.

The technology is not new. In the food processing sector, it has long since been tested on long baking lines – however, there the space for the blowers that move the hot air plays a subordinate role. The situation is different for high-performance ovens for front cooking: so that they fit on the shop counter, the space for the technical components is quite limited. Here, AC technology cannot achieve a power density comparable to the EC fan.

But in the food processing sector, EC technology offers potential for process optimization thanks not only to its enormous power potential with greater energy efficiency, but also with respect to its possibilities for networking.

Great performance in a compact package

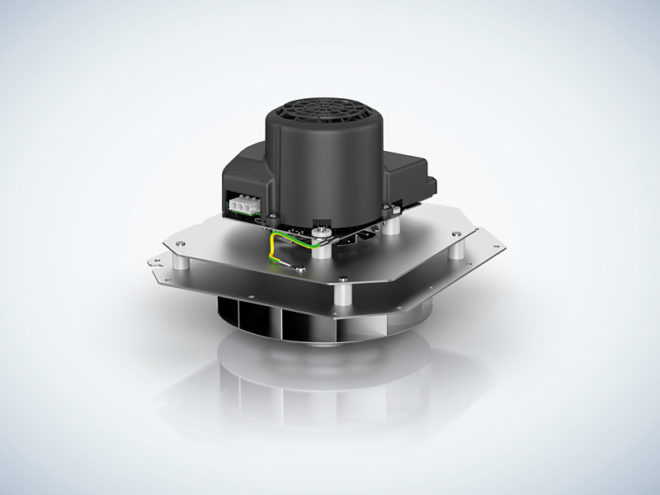

Blowers with EC technology have the advantage that they require little space yet nevertheless provide great power. Their compact size is possible because the electronics are arranged flexibly around the EC motor and also because the motor requires no variable frequency drive (Figure 2). Therefore, blowers with EC technology are predestined for compact high-performance ovens (Figure 3).

The VBS 170 centrifugal blower (formerly the R170) with EC motor from ebm-papst was adapted especially for use in such applications. Its speed of more than 3000 rpm and its backward-curved blades ensure great aerodynamic efficiency with low energy consumption. This makes high pressures with high air flow possible.

The advantages are best displayed when the design of the EC blower is attuned to the flow design. That’s why, on request, ebm-papst engineers work closely with manufacturers, even during the design phase. Since ball bearings are used for the blowers, there various ways to install them. A sleeve bearing wouldn’t work since it can’t always accommodate forces in an axial direction. Heavy, hanging or horizontal impellers would quickly wear down the bearing.

Another advantage of EC blowers is their dynamics: they accelerate very quickly to the desired nominal speed. No valuable seconds are lost when they are heating up. 16 hours of continuous operation is not a rarity with these compact high-performance ovens. For a high level of availability and correspondingly high sales of ready-to-eat foods, robust technology is indispensable. Here too, EC technology scores points with its long service life and low wear.

All advantages at a glance

The VBS 170 blower solution from ebm-papst is optimally attuned for use in high-speed ovens:

- The EC technology unites a lot of power with a small space, which makes compact devices possible.

- The centrifugal fan impeller is made of stainless steel, so it fulfills the hygiene requirements of gastronomy.

- The motor is vibration-damped on a special mounting plate and fastened so that it is thermally decoupled.

- The noise emissions are low thanks to the design of the blower.

- Long service life even with constant use due to robust EC technology.

- EC systems can be networked easily, entirely in the service of GreenIntelligence.

Technical data

The most important facts and figures about the VBS 170 blower solution:

- Maximum power consumption: 300 W

- Nominal voltage: 230 V AC 50/60 (additional voltage ranges on request)

Heat-resistant, quiet, and hygienic

Due to their compact designs, the blower and heat source are close together in these ovens. However, the high temperatures cannot harm the technology: ebm-papst engineers have relied here on their many years’ experience in the heating technology sector and decoupled the fan and motor (Figure 4). These are on two levels that are separated by thermal decoupling elements. If necessary, an additional cooling impeller reduces the thermal load on the motor’s electromechanical components.

Fig. 4: The fan and motor unit are decoupled from one another. This means the blower is well-suited for use in the high-temperature range. The decoupling elements also reduce noise emissions that contribute to structure-borne sound.

This design principle also results in lower noise emissions. Because the ovens are frequently in the sales area, volume is a decisive factor. Customers shouldn’t be disturbed by noise. Thanks to the decoupling, the mounting plates are spring-mounted, there are few vibrations, and structure-borne sound is correspondingly low. In addition contributing to the aero-acoustics, this means that noise is kept under control.

The fan’s wheel is made of stainless steel, which does not rust in the humid-hot work environment. ebm-papst blowers therefore fulfill another important prerequisite in the gastronomy sector: compliance with hygiene regulations.

Ready for the future

Digitalization has long since arrived in the professional kitchen sector: many devices are already Internet-capable and therefore networked. Precisely for larger franchise companies, this is a big advantage, since they can program new cooking programs centrally onto hundreds of high-speed ovens and delete old programs.

But that is not the only benefit of connectivity! ebm-papst’s EC technology can also be incorporated easily into existing communication structures, entirely in the service of GreenIntelligence. An important prerequisite if in the future topics such as the recording and evaluation of operating states in general or predictive maintenance are supposed to become reality.

Leave a comment