The newly developed oven generation of Swiss premium household appliance manufacturer V-ZUG is a combination of reliable appliances that are easy to operate and modern technology. And it leaves room for major culinary triumphs, because the ovens that have been in the market since February 2019 have significantly larger cooking spaces. Although the device of the Swiss market leader in the white goods market is as compact as its predecessor, even the largest turkey will fit inside.

Andreas Büeler, development engineer at V-ZUG (Photo | V-ZUG)

“To achieve this, we had to reduce the installation space and the height of the device’s operating panel,” said Andreas Büeler, a development engineer at V-ZUG. “This left less space for the stove jacket cooling – the height in particular was much lower,” added his colleague, Pascal Bosshard, who helped develop the ventilation system. The company was presented with a challenge, because the air throughput had to remain the same despite the reduced space. Some models even required higher air throughput, and the ventilation system had to cool as quietly as the previous model.

No simple solution

Relying on a more powerful motor was not the solution because stove jacket cooling systems have several functions. They ensure that the walls and door do not become too warm, cool the lamps inside the oven, and remove moisture from the cooking space in order to produce optimal baking results. Each area must receive sufficient air, but at the same time the motor must be designed specifically for the baking process to ensure the proper climate and temperature inside the oven. To satisfy all these requirements simultaneously, the two engineers reached out for support from ebm-papst. Until that point, the ventilation specialist had only supplied motors. V-ZUG developed the fan impeller and assembled both components in-house. For the first time, the company planned to rely on a complete solution.

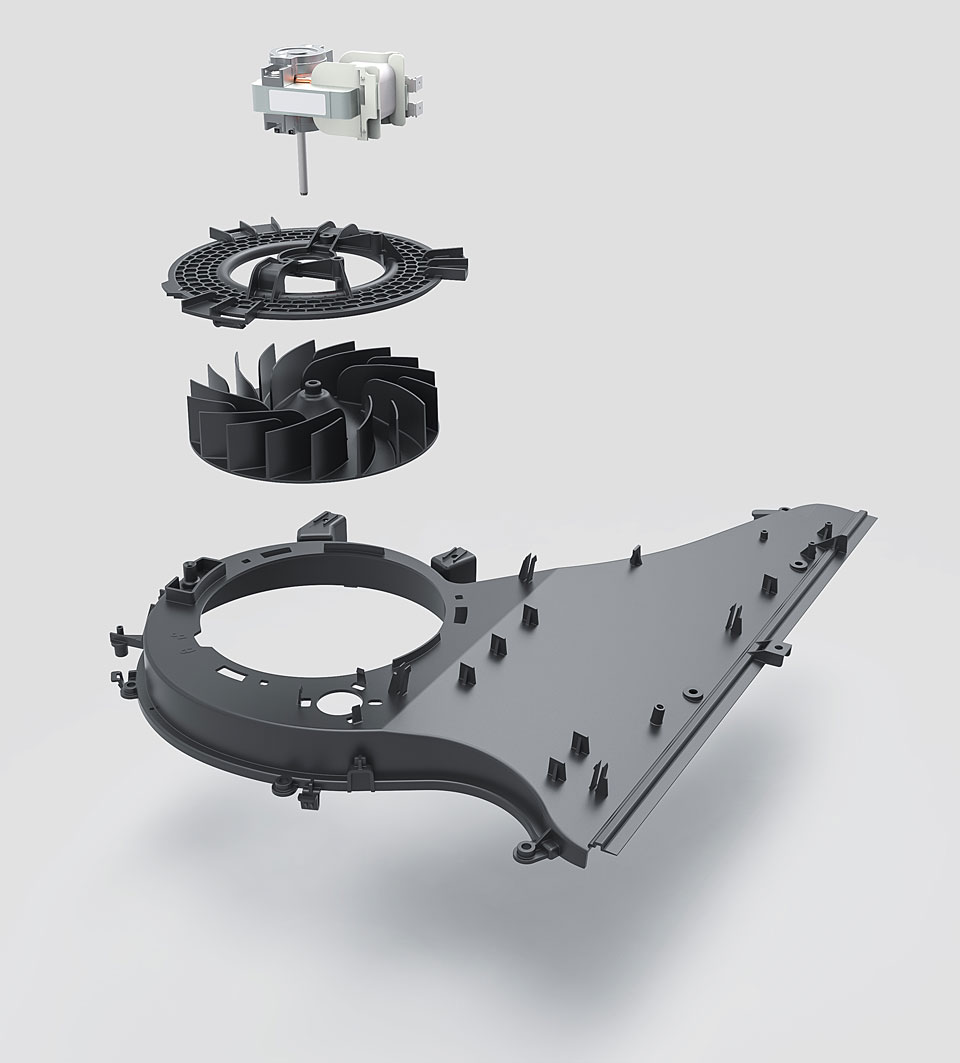

The solution consists of a customer-specific, backwards-curved impeller and a slow-running shaded-pole motor with a motor power of 15 W and custom, flat bearing supports. (Photo | V-ZUG)

“Initially, many variables – such as the impeller diameter and the fan’s blade geometry – were open,” said Bosshard. “ebm-papst helped us get down to the specifics.” After the product analysis, they ran simulations. V-ZUG developed the impeller and housing in collaboration with ebm-papst’s Landshut location. The Swiss engineers joined ebm-papst at the production site in Slovenia to select the motor and optimize the installation height. It took the engineers two years of combined work and many trips back and forth to develop the solution.

The team hits the right note

Pascal Bosshard, development engineer at V-ZUG (Photo | V-ZUG)

V-ZUG and ebm-papst worked in particularly close collaboration starting in spring 2018. “The stove jacket cooling system was basically finished. ebm-papst had developed a combination impeller and motor that met our requirements for size, air pressure, and noise level,” said Büeler. “But we were not happy with the way the ventilation system sounded.” He and his colleague wondered if the high frequency would disturb the company’s sophisticated customers when they used the oven in the kitchen. “The ebm-papst team understood what we wanted and despite the tight deadline, was immediately willing to go another round to optimize the solution,” said Bosshard.

They tested and tested, and finally found the solution. It consists of a customer-specific, backwards-curved impeller and a slow-running shaded-pole motor with a motor power of 15 W and custom, flat bearing supports to minimize installation height. Motor mounts with an aerodynamically optimized inlet ring and snap connectors ensure that the motor can move sufficient air despite its compact size.

“The ebm-papst team understood what we wanted and despite the tight deadline, was immediately willing to go another round to optimize the solution”

Pascal Bosshard, development engineer at V-ZUG

“We are now using a shaded-pole motor that we could only use to sufficiently cool steamers in the past,” explained Büeler. “But the oven now gets up to 70 degrees warmer.” After ebm-papst’s optimizations, it was finally possible to use the motor for heat jacket cooling as well. “It really helped to have ventilation specialists at our side who supported us with their know-how,” said Bosshard in summary. “We had a team with whom we could make the right decisions quickly and arrive at an excellent result.”

Leave a comment