Apeldoorn, Holland, in the not-too-distant future: A heating technician sets out for an apartment building in the city center, where he is to service the water heater. But his assignment isn’t from the building’s owner. It’s from the heater in the cellar, which reported the problem by itself via Internet. The technician was already able to make a diagnosis on the computer and bring along the required replacement part.

If it were up to Ton van Maaren, this would soon be an everyday scenario. “We’ve established the technical foundation and the first projects are already in progress,” says van Maaren, senior product manager at Remeha, a heating company from Apeldoorn, Holland. Anyone listening to him can quickly tell that he knows exactly how the boiler market works. After all, he has been with Remeha for 33 years. When he started there, the company was still small. Since then, Remeha has become part of the BDR Thermea Group, which has operations worldwide.

Saturated markets

Remeha: From mid-sized company to global player

When the businessman Gerard van Reekum founded “van Reekum’s Metaal Handel” in Apeldoorn, Holland, in 1935, most households still heated with coal-burning stoves. At that time, the young company supplied steel pipes and fixtures to the heating industry. When central heating became popular, Remeha developed its first water heaters in the 1940s. In the following decades, the company continued to develop its expertise in this field. Since 2009, together with brands such as De Dietrich, Baxi and Brötje, Remeha has belonged to the BDR Thermea Group B.v., which is headquartered in Apeldoorn and has a total of 6,400 employees.

At the beginning of van Maaren’s career in 1983, condensing boilers were still relatively new. “Nowadays 99.9 percent of the boilers sold in Holland are equipped with condensing technology. The trend is similar in other European countries. So the market is nearly saturated and is barely growing anymore,” says van Maaren. If Remeha wants to gain market share, it has to offer more than just efficient and clean combustion. “A lot of the development work is no longer related to combustion technology, it’s about aspects like easy installation and maintenance, user-friendliness and, most importantly, digitalization. Smart devices that can communicate are becoming more and more important.”

Devices that decide on their own whether they need servicing and for which remote diagnosis with a computer is possible could soon be part of the standard repertoire for boilers. But as van Maaren emphasizes, that’s up to the manufacturers. “When it comes to innovation, the boiler market is actually pretty sluggish. We manufacturers have to show the market what’s technically possible and worthwhile. We can’t allow ourselves to wait until the market asks for it.” So Remeha’s new boilers are Internet-capable and ready for the digital future.

Power on the wall

In the company showroom, the product manager shows Remeha’s latest product, the Quinta ACE. The boiler, which measures only 100 x 60 x 60 centimeters, has an output of up to 161.5 kilowatts and hangs on the wall to save space. The unit has been on the Dutch market since the beginning of 2016. It supplies heat for apartment buildings, schools, hospitals or offices and industrial buildings. “Previously there were only floor-mounted units in this output class since they were too big and heavy to mount on walls. They need a lot more space and also take much more effort to install,” says van Maaren.

“We supply complete modular systems. The installer only has to hang up the boilers and screw the prefabricated parts together.”

Ton van Maaren, Senior-Produktmanager Remeha

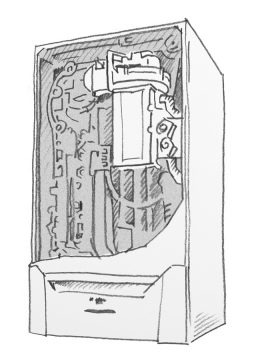

Since the boilers hang at chest level, installers no longer need to crawl on the floor during installation and maintenance. And fewer interfaces means there is little effort required for installation.If higher output is needed, up to eight boilers can be cascaded to reach a total output of 1,292 kilowatts. “We supply complete modular systems for that. The installer only has to hang up the boilers and screw the prefabricated parts together.” What sounds so simple had a very busy background story. More than four years of development work went into the high-powered boiler. “The challenge was to fit all of the components into a limited space,” says van Maaren, adding “For that we needed dependable development partners.”

Compact all-in-one solution

The gas-air unit from ebm-papst

The right gas-air ratio is crucial to optimum energy yield, so the blower, venturi, valve and combustion controller have to be perfectly matched. The venturi provides the correct gas-air ratio. The blower draws in this mixture for combustion in the burner. The valve regulates the gas quantity depending on the vacuum produced by the blower in the venturi. And the combustion controller is responsible for controlling the system as a whole. It sits directly on the blower, so it gets cooled and needs no elaborate wiring, saving space and installation time.

The boiler’s modular construction enables its compact design. “As in the automotive industry, for some time now we’ve been taking the approach of installing system solutions. That improves the quality,” says van Maaren. As proof he points to a condensing boiler in the showroom, the Tzerra, designed for use in private households. “In this unit, for the first time we used a preassembled gas-air module with a combustion controller from ebm-papst that was specifically developed for it.

Perfect interplay among these components is crucial for optimum combustion.” While the Tzerra had an output of 28-40 kilowatts, the Quinta ACE with its 161.5 kilowatts was a step into a new dimension. ebm-papst developed a new all-in-one solution; in addition to the venturi, valve, blower and combustion controller, even the burner is integrated. Such a complex system from a single source is unique on the market so far,” emphasizes van Maaren as he heads for the manufacturing facility.

Quick installation

There another advantage of the modular construction becomes apparent quickly. All the workers there have to do is place the gas-air unit in the boiler, tighten a few screws and connect the cables. After that only a few more steps need to be performed before shipment. Since its launch at the beginning of 2016, hundreds of Quinta ACEs have been installed in Holland. “For a new boiler in this output class, that are very impressive volumes.

Soon they’ll also be on the market in other European countries,” says van Maaren on the way back to his office. There he attends to the next project. “We’re in the process of adapting the gas-air unit for higher output classes. They’re still too heavy for the wall. But who knows what the future will bring.”

Leave a comment