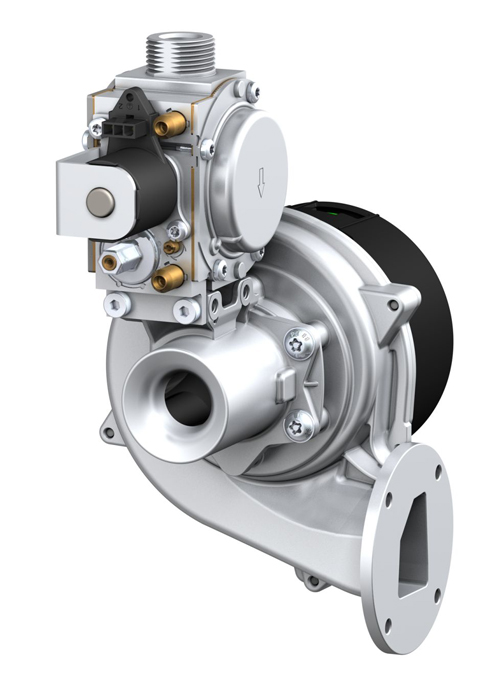

The NRV 77 is a system for gas condensing boilers consisting of the NRG 77 blower, an innovative multi-venturi and E 01 gas valve. In order to co-ordinate these single components optimally with one another, we had to overcome three major hurdles.

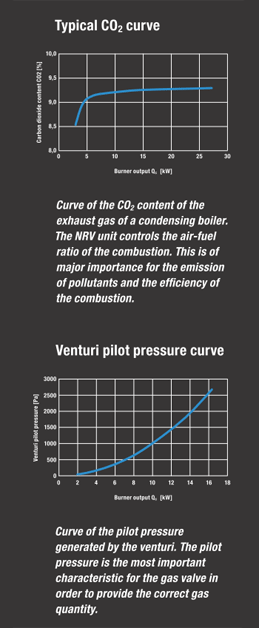

Typical CO2 curve and Venturi pilot pressure curve

The fan covers a power range from 1 to 35 kilowatts. It is operated at speeds up to 11,500 revolutions per minute, yet is significantly smaller than its predecessors. We are working with a smaller impeller diameter in order to satisfy the requirement of our customers for ever smaller heat outputs. This also presents new challenges for the bearing technology, since the friction torques gain greater significance. Therefore, it was important to guarantee the correct balance between viscosity of the grease and the service life of the fan. We safeguarded this by means of numerous endurance and development tests.

EA constant fuel-air mixture across the entire operating range is highly significant for the function of the gas condensing boilers. NRV systems have a large modulation range from one to seven, over which the air-fuel ratio of the combustion has to be controlled. What is called the main injection throttle of the gas valve is an important element here. It is used to configure the desired gas volume flow at full load. It consists of a rotating plastic part, which is fastened in place on a sheet.

The parts have to be flushed with one another to ensure that the entire gas quantity is fed through the main injection throttle and no leaks past the throttle can develop. These leaks would have a negative impact on the smallest attainable partial load of the gas condensing boiler. And this partial load – as many customers require – should be as small as possible. In order to fit the plastic part to the sheet metal better, we temper it. We were also able to further optimise the sheet metal part since we have long-time experience with punches in the Production department in Landshut, Germany. Thus we were able to achieve the goal of creating a largely leakproof main injection throttle that can be moved ideally.

A single venturi cannot cover the large power range of the fan. However, we wanted to find an easy and cost-effective solution for adapting the venturi to the power range desired by the customer. To do so, we created a venturi with an integrated displacement body. The displacement body forms the actual venturi diameter. This diameter can be easily modified, yet it does not worsen the performance. Additionally, the entire venturi can be flexibly attached to the fan in many different mounting positions. This brings flexibility to the customer and fewer design variations for us. We have had this solution patented and call it “multi-venturi”.

The system solution consisting of blower, venturi and valve makes co-ordination easier for developers of gas-fired heaters. Additionally, the perfect interaction of the individual components improves efficiency and reduces costs.

Where can i buy it?

Dear Zhou,

Thank you for your request – We have forwarded it our sales team.

Best regards,

Your mag°-Team