Enjoying comfortable warmth in a home with central heating with a clear conscience, despite the ever-rising natural gas prices and emissions. Remeha wants to make this dream come true for even more end customers. Remeha has taken up the cause of cost-effective, groundbreaking technology and has been specialising for over 30 years as one of the leading suppliers in the field of gas condensing boilers. For that reason, in 2012 the heating specialist will bring to market a cost-effective, compact condensing boiler for private households: the device is called Tzerra. The new boiler should be attractive above all for customers in countries where, to date, conventional heating systems have been more likely to be implemented for cost reasons. Tzerra is particularly space-saving, ultralight with only 17 kilograms and represents a new technical development.

The core point of the innovation is the design’s use of a modular system. The entire device consists of only four modules, which are assembled at Remeha: a housing and frame, a heat exchanger and burner, a gas-air unit with a burner controller and hydraulic components with a recirculating pump. For the development and construction of the gas-air unit, Remeha charged ebm-papst with the task of combining all the parts in a single, ready-to-install set.

In Landshut, the entire gas-air module is designed, developed and built as a unit for the first time for the Tzerra boiler. According to the requirements specification, it is to assume total control of the boiler and deliver the air-gas mixture to the burner. The solution includes the following parts: mixing adapter, blower, gas-air ratio controller – what is called the venturi nozzle – gas valve, intake noise filter, boiler control system, safety component and ignition transformer.

As an innovation, ebm-papst designed the gas-air module as a compact, integrated complete system, which includes the blower, gas valve, burner controller, mixing adapter and the electronics for the burner controller and blower combined on one board. “The objective was to save space, while simultaneously developing a simplified plug-and-play method for assembly and maintenance,” explains Gerhard Selmer, Key Account Manager for Remeha in Landshut. “Both help reduce the costs for the device significantly.” The complete system ensures that the components are optimally matched to each other and therefore work efficiently. This co-operation means improved efficiency for Remeha as well: Since everything comes from single sources, the administrative effort is reduced.

During its two-year work, the Landshut development team was able to draw from its long-time experience in blower and control technology – as well as burner controls. These are responsible for controlling the centrifugal blower used – an NRG 118 – and by actively controlling the gas valve, it makes sure the gas being supplied is burned in a controlled fashion. The burner controller uses a communication interface developed jointly by ebm-papst and the Dutch subsidiary Argus Vision to transmit the speed to the blower directly and digitally. This enables the blower to assume the accurate speed control itself and thereby react even faster to changes in the ambient parameters. Maintenance and repairs are also simplified, since the blower’s operating data, such as speed, motor current, operating time or ambient temperature, can now be transmitted via the interface. On the one hand, these parameters allow potential problems to be discovered in advance and corresponding warnings to be issued in the control display. On the other hand, this information significantly eases troubleshooting when a repair is needed, which also results in reduced downtime.

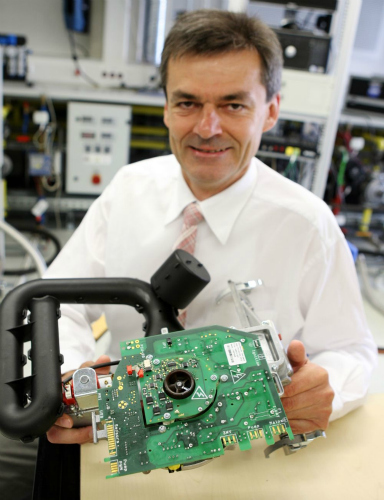

Hans-Joachim Klink, Design Manager at ebm-papst Landshut, and Gerhard Selmer (from left) during the weekly videoconference with the Remeha team

To be able to offer such system solutions, at the beginning of the year ebm-papst had expanded its product range by adding a gas valve, which has now benefited the Tzerra’s development. This gas manifold with the patented coaxial safety valve is integrated into the gas-air unit in a space-saving manner. The requirements placed on the aluminium die-cast part of the housing with mixing adapter were also stringent. Here, particularly the narrow flatness tolerance that is mandatory for gas-tightness is something that can be reliably achieved at the specified dimensions only with a lot of specialised experience.

For the first time, the controls for blower and burner controller are combined in a single printed circuit board for the Tzerra. As a long-time partner, Argus Vision contributed its expertise in automatic gas stokers for this centrepiece. But that isn’t all. Landshut specially built a new production line for series production of the entire unit. Each individual unit is inspected at the end to make sure it functions. Landshut developed special testing technology and built automatic testing devices for this, as Remeha expects a maintenance-free minimum service life of 15 years.

To fulfil this requirement, ebm-papst already conducted test runs and measurements using all specifications during the development phase. These included, for example, service life tests in climate chambers, tests with various gas types and operating modes as well as tests for vibration and shock resistance and noise level.

Remeha expects the Tzerra condensing boiler – cost-effective to purchase and operate – to attract wide interest in private households as an environmentally friendly alternative to conventional thermal power devices. Comfortable heat with a low impact on the wallet and environment – winter can come!

Condensing boiler technology

With the condensing heating concept, the efficiency is significantly higher than with conventional heating systems, because it additionally uses the heat of the exhaust gases generated. Condensing boilers operate with large heat exchangers, through which the water vapour condenses inside the device. The condensation heat is fed back to the heating circuit; as a result, it increases the “standard efficiency” to 109 percent and thus reduces the heating costs by up to 30 percent. An essential aspect is the lower environmental impact: The proportion of carbon monoxide (CO) is about a fifth lower and

the proportion of nitrogen oxides (NOX) about a third lower with condensing boilers than with older heating units.

Leave a comment