It is particularly important to ensure the best possible storage of information relating to the judicial system, the police and the tax authorities. This applies not just to the encryption and storage of the actual data, but also to the hardware on which they are stored. So it comes as no surprise that reliably air conditioned server rooms are a top priority for the Canton of Zug.

Modernization of their recirculation coolers was a prime concern of André Lötscher, Technical Manager of the Canton of Zug Structural Engineering Department. “For years the belt-driven fans in our cooling units have been constantly running to full capacity,” explains Lötscher. “The V-belts required regular checking and had to be replaced in the event of excessive wear, and we had to react instantly if they tore.”

“Our recirculation coolers satisfy exacting requirements”

André Lötscher, Technical Manager of the Canton of Zug Structural Engineering Department

That is why he urgently wanted to modernize the recirculation coolers and replace the old fans at the same time. Further objectives were better control characteristics and closer monitoring of the system. Lötscher would only consider complete replacement of the units as a last resort: “Our recirculation coolers satisfy exacting requirements in terms of shock resistance for example and cannot simply be replaced by a standard unit. The complete replacement of all units would be pretty expensive and a lot of work.”

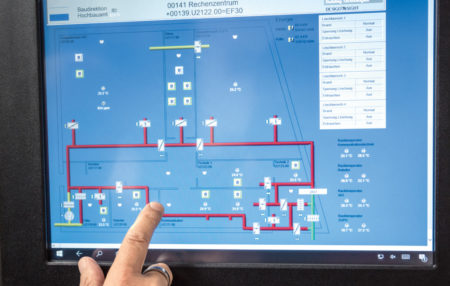

Everything at a glance: Thanks to MODBUS-RTU, the fans are perfectly integrated into the control system.

So Lötscher made a few inquiries and finally obtained the number of Inframatic, a small company near Basel specializing amongst other things in building automation and air conditioning systems for all sorts of rooms. Not long afterwards he called Project Manager Stefan Haydn, who came up with a few ideas straight away. He set a date for a visit to Zug, and brought Daniel Spurgeon, Area Sales Manager at ebm-papst, with him.

“This solution makes it easier for us to coordinate the interaction of all components.”

Stefan Haydn, Inframatic Project Management

AWhen the three of them inspected the premises and the cooling units, it became apparent that the best alternative for the Canton’s data center would be to replace the belt-driven fans with EC fans — this would not only get rid of the old fans but also reduce current consumption.

“In our discussions we also talked about the options available for control and monitoring of the fans,” recalls Stefan Haydn. “The minute I heard that the ebm-papst fans can be actuated and monitored via MODBUS-RTU there was no doubt in my mind that this was the course to follow.”

Precision control

In the weeks that followed, Inframatic first had five recirculation coolers converted. Thanks to the use of RadiFit fans and EC centrifugal blowers with a high power density, the hardware retrofit took no time at all. “The fans from ebm-papst permitted virtually 1 : 1 conversion, completely straightforward,” says André Lötscher. Installation of the RadiFit fans, that were developed for precisely such cases, was particularly easy.

With regard to control, Inframatic had a few clever ideas on how to make operation even more efficient. As the belt-driven fans only had two speed settings prior to upgrading, the temperature was largely regulated by the opening of the cooling registers. The experts completely reversed this less than ideal energy principle in the converted recirculation coolers.

Stefan Haydn from Inframatic explains the fine workings of the system that controls the fans and the flow control valves.

The output is now controlled via two sequences: In the first sequence, the cooling capacity is regulated by the flow control valves and in the second by the fans. This is made possible by the fact that the fans are infinitely adjustable. The speed at which the fans rotate is controlled automatically by temperature sensors that measure the exhaust air. If the air is too warm, the cooling valve is fully opened and the fans rotate from a defined minimum speed up to the maximum speed. If the air is too cold, the fans turn more slowly and the cooling valve is closed. This ensures that the temperature in the server room never exceeds the specified 22 to 23 degrees Celsius.

A further advantage of the fans in the converted recirculation coolers is actuation via MODBUS-RTU. “It absolutely suits our purposes that the fans, along with other components in this application, can be actuated and monitored via MODBUS-RTU,” explains Stefan Haydn. “That makes it easier for us to coordinate the interaction of all components.” In contrast to a 0 – 10 V connection, MODBUS-RTU allows not just control, but also monitoring of the fans. They pass detailed data such as voltage and current draw, as well as alarm messages, to the higher-ranking control system for instance. This in turn transfers the data to the management system, which collects information on all the building services in general. Via the interface with a touch panel the administrative staff of the Canton can thus view individual values and set various parameters.

Simplified maintenance

Well informed thanks to MODBUS-RTU

As compared to actuation by way of a 0 –10 V signal, the incorporation of fans via MODBUS-RTU offers a whole range of advantages. For instance, a fan can not just be actuated via MODBUS-RTU, it also passes information on its operating status to the control system. This includes power consumption, current speed, the number of operating hours and detailed error messages. In addition, MODBUS-RTU makes it possible to connect multiple fans with a single cable, thus reducing the amount of installation work.

„“The more detailed warnings really are a great help,” says Haydn. “They make it easier to see whether a problem is just a passing anomaly or a fault requiring a technician to take a closer look in the server room.” MODBUS-RTU also made control system adaptation and addressing of the fans more simple for Inframatic. “With our EC Control software, customers can check developments and parameter settings quickly and easily,” explains Daniel Spurgeon. “That saves time and is particularly helpful at the outset of a development.” To ensure even greater reliability, critical rooms are equipped with two recirculation coolers. These are operated in a master-slave configuration so that all the fans in the units run at the same speed.

Delighted by the simplicity of the process, Lötscher ordered the conversion of more units immediately after modification of the first five recirculation coolers: Once all the systems in the data center had been modernized, work started on the ventilation system of the police firing range and headquarters and in an adjoining prison building. “When you have seen just how well the conversion works and how economically attractive such measures are, you start to realize there are any number of other opportunities,” says Lötscher. “What’s more, our air conditioning system is now not only more modern, it is also far more energy-efficient.”

Leave a comment