Sometimes Iain Port can’t help it. He just has to ask other passengers — complete strangers — what they thought of the security gate they just went through. “I usually get irritated looks when I ask,” says Gunnebo Entrance Control’s R&D and Operations Director, laughing. His colleague Nick Elkins also keeps his eyes open for gates around the world. “But I wouldn’t normally approach strangers to ask their opinion about our gates, I would typically just tell the person I’m with that they’re going through a Gunnebo product,” says the company’s Design Engineer New Product Development.

Both of them usually have a lot of opportunities to see their own security gates in action: Gunnebo, based in Göteborg, Sweden, has 5,800 employees spread across 31 countries. In normal times, business trips are commonplace.

Development of safety gates at four locations

The members of the Gunnebo team that has been working for the last couple of years to design a new security entrance gate are situated in various different parts of the global Gunnebo Entrance Control business unit. Port and Elkins work at the British Gunnebo site in Maresfield.

Wanted a new solution for motor control: firmware developers Francisco Kedjagni and Daniele Zanini.(Photo | Mattia Balsamini | Fotogloria)

The firmware developers Francisco Kedjagni and Daniele Zanini are based at the Gunnebo site in Lavis, Italy, and the production team based in China also played an important role. The global ebm-papst network also provided support.

The aim of the collaboration, which, before coronavirus, involved a lot of travel, was to optimize the performance of a Metro Fast Lane barrier (MFL), i.e. automatic ticket control gate, which can be found in many metro stations. Gunnebo usually develops complete gates, but this time the project involved redesigning the core component, the mechanism, which ensures that the swing doors open as quickly as possible when someone wants to get through with a valid ticket and then closes shut equally as quickly before the next person, and that anybody without a valid ticket is stopped and prevented from passing.

Gates must open and close quickly

There are a number of challenges that must be overcome when designing a fast moving barrier. After all, they have to open and close very quickly, and there is a risk that it could make contact with a user whilst moving.

“The problem is the physics: The faster something moves, the more powerfully it can close on someone.”

Iain Port, R&D and Operations Director, Gunnebo Entrance Control

Port explains: “The problem is the physics: The faster something moves, the more powerfully it can close on someone or something and potentially cause injury. But at Gunnebo we are committed to the safety of the user and therefore we need to find a way to move fast but with very low impact forces.” The experts from Gunnebo also have to provide a door that will stop people from pushing through in normal operation but that will also release to allow crowds ‘push through’ in the case of panic, for example, “it must not become a blocking obstacle in an emergency,” says Elkins.

The Gunnebo team got support from Germany to outsmart the physics: market manager Stefan Rötzer and project engineer Dominik Häßler traveled from ebm-papst to Lavis many times. Because, as Francisco Kedjagni explains, “We have a number of existing products with really good performance but for this specific application we decided to work with ebm-papst to develop a new solution because they are experts in motor control and exhibited a real desire to collaborate to find the best solution to this challenge.”

Slim, speedy, and smart drives

But what constitutes the best drive in this case? It needs to be slim and speedy, and also smart. The idea behind it is that, if the motor and transmission don’t require much space, the gate can be made slimmer. “The ebm-papst drive requires a third less space than its competitor product. At the same time, it’s significantly more efficient and, therefore, consumes less energy,” Rötzer explains proudly. “This enables completely new approaches to designing the entire gate and meets the highest environmental standards.”

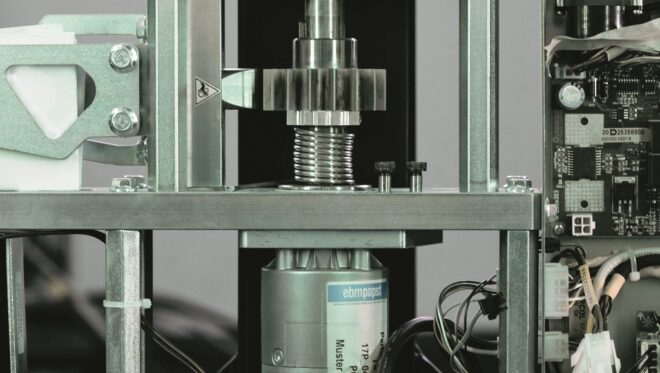

So small and already so smart: the ebm-papst drive requires a third less space than comparable products and knows when to stop moving the doors. (Photo | Mattia Balsamini | Fotogloria)

The smaller motor frees up space in the gate cabinet for other peripheral equipment to be fitted and also makes the overall package appear more slimline and aesthetically pleasing.

To ensure that the impact force from the gate was not too high, the project team not only worked on making it speedy, but also worked on making it smart: with the new drive, the doors complete a 90 degree swivel movement at the blink of an eye. If the doors meet an obstacle, the motor detects the impact immediately through the onboard controller and reacts according to the customer’s preferred option: stop, reverse, or drive with low energy. “A clean bit of engineering work,” praises design engineer Elkins.

Testing for secure passage: countless tests were carried out by design engineer Nick Elkins to find out when the doors give way. (Photo | Mattia Balsamini | Fotogloria)

Tests of the swinging doors with physical effort

He would know. He carried out some of the many tests that Gunnebo used to check the quality of the drive and the interaction of the components: On a sturdy test stand, Elkins engaged his strength to test the push-through system design and evaluate the performance boundaries the swing gates would give. His Italian colleagues used the same physical effort to check the impact force of the gates using different motor / controller / gearbox / firmware combinations. Their laboratory houses complete gates that have been through a rigorous development and test process “and we have seen some very interesting results along the way,” says firmware developer Daniele Zanini.

“It was an exceptionally smooth process. It’s not usually so easy to get the drawings or the CAD models you need, for example.”

Nick Elkins, Design Engineer New Product Development

The collaborative work on the MFL was not boring, even outside the laboratory: There was some time to relax together in the beautiful local surroundings at the end of long days of testing, enjoying the local restaurants in Lavis.

Daniele Zanini was to find out how the motor, controller, gearbox, and firmware complement each other perfectly. (Photo | Mattia Balsamini | Fotogloria)

But, with the utmost respect, the men from Gunnebo were convinced by something else: “Working together we agreed on the best implementation of the drive control system and then spent a long time developing and refining it. There were many challenges to overcome throughout the process. But with support from Dominik and Stefan we achieved our main aim of having a low impact force, and a super fast and smooth motion,” says Zanini. Elkins agrees with him: “It was an exceptionally smooth process. It’s not usually so easy to get the drawings or the CAD models you need, for example.”

The optimized Gunnebo gate is due to be launched soon. So if someone asks you what you think of a security gate in future, just praise the speed and movement of the wings: it could be Iain Port, who would be very pleased.

A very interesting application of Planetary Gearmotors