Permanently excited electric motors rely on permanent magnets due to their function. Especially strong magnets can be produced in the sintering process from compounds with rare earth materials, such as samarium cobalt or neodymium iron boron. After the artificial scarcity of these materials and the resulting drastic rise in costs, the prices have been falling recently. However, since now as before China controls a large part of the quantity supplied, the user must continue to reckon with extreme price fluctuations. Likewise, availability is not guaranteed.

Also in future, the costs for rare earth magnets will be very difficult for the manufacturers of electric motors to calculate. Therefore permanent-magnet excited electric motors, which are particularly energy-efficient, are often regarded as expensive in user circles. It is not necessary, however, that each electric drive operating with high efficiency also really depends on strong rare earth magnets. EC motors with an external rotor design, for example, which are used in energy-saving fans, run with “simple” and cost-effective and anywhere available ferrite magnets, and they work at efficiencies of over 90 % in some cases.

What is an EC motor?

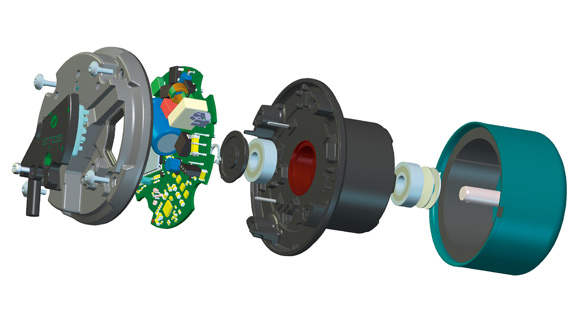

Since the terms in drive technology are not necessarily always used with clear and unambiguous definitions, it makes sense first to clarify which motors are actually meant in conjunction with the rare earth discussion. Whether a brushless DC motor (BLDC), a brushless permanent-magnet (BLPM) motor or an electronically commulated (EC) motor, always means a permanently excited synchronous motor, which is operated with power electronics – mains-powered or with a DC power supply. The so-called BLDC/BLPM motors are usually operated with square-wave currents (block commutation). The EC motors can be operated with square-wave currents as well as with sinusoidal currents (sinusoidal commutation). Doing the latter the drive achieves a significant noise reduction over square-wave currents. The design with sinusoidal currents corresponds to the classic synchronous motor. The basic function of the EC motor is easy to understand (Figure 1):

Figure 1: Exploded drawing of the permanently excited synchronous motor, also called brushless direct current motor or EC motor.

The rotor, which has permanent magnets, rotates synchronously with the rotary field of the stator. Unlike the mains-powered asynchronous motor, the rotor speed is not automatically coupled to the frequency of the supply voltage, but it is determined by the commutation electronics. Therefore operation of the EC motor always requires additional electronics. This determines the angular speed of the stator rotating field, at which the rotor synchronously rotates. The correlations between voltage and speed and between current and torque are largely linear. Consequently, with respect to its torque-speed characteristic, the motor acts like a DC shunt motor.

To detect the rotor position, either rotor position sensors are integrated in the motor, or the commutation electronics measure the rotor position without sensors via the parameters field EMF and motor currents. The no-load speed depends on the applied voltage and the number of windings of the stator winding. Therefore in the limits which are defined by the physical parameters (such as output power, torque, temperature rise etc.), nearly arbitrary operating speeds can be implemented slip-free (synchronous with the stator rotating field), which can even lie above the power frequency, unlike the mains-powered asynchronous motor. For example, if a fan is operated with an EC motor, the speed can always be adapted to the requirements of the ventilation system or the process. In partial-load operation, therefore, the energy consumption can be significantly reduced, because the required input power of a fan changes according to the speed to the power of 3.

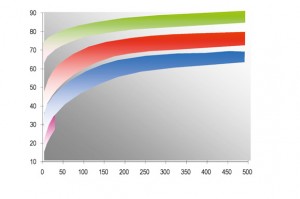

Aside from this, EC motors feature a significantly higher efficiency (Figure 2) than mains-powered AC motors both in partial-load operation and at full load, and they usually do this with a smaller size. One reason is that EC motors do not require a magnetising current, so that current heat losses of the rotor disappear. Another reason is the possibility to implement a special winding arrangement with a low end winding (single-tooth winding / concentrated winding, which reduce the winding losses). Even if the rare earth magnet discussion does not favour these motors, they are simply the best choice in terms of energy efficiency.

Dynamic requirements determine the choice of magnets

With EC motors you are not always forced to rely on the strong rare earth magnets, because their excellent magnetic quality is really needed only for highly dynamic servo drives, such as those used in robotics. On the one hand, compact dimensions are required; on the other hand, however, the lowest possible rotor mass is required to minimise the moment of inertia. These requirements are attainable only with highly remanent and highly-coercive rare earth magnets. Therefore, manufacturers of such servo drives primarily concentrate on reducing the required magnet mass and height by means of complex optimisations; and they have already achieved very remarkable savings here. Motor and fan specialist ebm-papst Mulfingen is not even faced by this problem with its fans, which are equipped with energy-efficient GreenTech EC motors. Despite the high efficiency, these drives run without rare earth magnets. The external-rotor motor principle provides the key for this:

The rotor is on the outside

Figure 3: Cutaway drawing of centrifugal fan with external rotor motor – the rotor rotates not in, but about the stator.

At this kind of motor, the still-standing part, the stator, is located on the inside and is surrounded by the rotating part, the rotor (Figure 3). The externally positioned rotor rotates about the internal stator. Conditioned by this arrangement, the external rotor motor can achieve a higher torque (magnet volume, air gap surface, radius) than the internal rotor motor of the same package length, the same magnet system and the same magnet thickness (reduced magnet volume, reduced air gap surface, smaller radius).

By cleverly using the design parameters in the fan and blower area, an external rotor motor using hard ferrite magnets can attain torques and efficiencies which the internal rotor motor can achieve only with rare earth magnets (because of the limited volume and mass). Unlike servo drives, fans do not require high dynamics. Quite the opposite is required: a certain moment of inertia is desirable for the fans to have smooth starting and acceleration behaviour. Without restrictions rare earth magnets can be given up and ferrite magnets can be used, which are not only significantly more cost-effective, but also have stable market prices due to their availability.

The motor design with an external rotor is advantageous for fans in another regard as well. This way, the axial or centrifugal impellers can be mounted on the rotating rotor, thus directly on the “housing” of the motor (Figure 4). Compact dimensions, especially in an axial direction, are the consequence and cooling is made simpler as the moved air of the fan is also cooling the motor housing.

The design with sinusoidal commutation also provides for particularly low-noise operation. The energy-efficient GreenTech EC fans are therefore completely independent of the market trend of rare earth magnets.

Leave a comment