Formula One can be a hot business, for the drivers in the racing cars, for the audience in the sun-bleached stands, and also for the engineers who work in the team garage to prepare the cars for qualifying and racing. Paddy Lowe, Executive Director (Technical) at Mercedes-AMG Petronas Motorsport, knows all about that: “At circuits in hot climates such as Malaysia, temperatures in the garage can reach 40 degrees Celsius – and that’s compounded with almost unbearably high humidity.

In this environment it’s a real challenge for the team and drivers to maintain concentration and maintain peak performance over the four-day race weekend.” So it’s a good thing that Mercedes-AMG Petronas Motorsport has ebm papst, the cooling experts, as a Team Partner. “When we were discussing how to shape our cooperation, garage cooling quickly became a priority issue,” says Gareth Jones, Managing Director of ebm-papst Automotive & Drives (UK) Ltd. So ebm-papst, together with a long-time partner, took a close look at the problem and developed a system for cooling the team garage at circuits which have high ambient temperatures and no air conditioning system.

Flexible system

There was a wide range of requirements which needed to be considered. The solution needed to be portable, resistant to water and dust, easy to install and remove and most importantly, provide a noticeable cooling effect to the team. “To reduce the weight, we decided in favor of a water-cooled air conditioner, which is considerably lighter and smaller than an air-cooled unit,” explains Gareth Jones. While an air-cooled system would have weighed several thousand kilograms, the water-cooled unit only weighs in at 350 kilograms – and it’s very compact: 1.30 meters wide, 2.10 meters high and 90 centimeters deep.

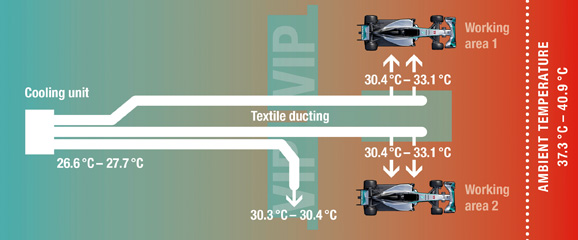

An additional challenge arose from the different layouts of the garages at the different Formula One circuits around the world. The team from Mercedes-AMG Petronas Motorsport divides the space into various areas such as bodywork, gearbox, wings, engineering, IT and tires as well as the working area for the two race cars. Two of the system’s air outlets cool the working area immediately adjacent to the cars at the front of the garage while an additional outlet ensures cool temperatures in the guest viewing area to the rear of the cars. However, the cooling unit itself needs to be located in the rear part of the garage to avoid taking up too much space.

Textile ducts transport the cool air from the cooling unit over up to 25 meters into the area where the engineers work at the cars and into the guest viewing area.

Therefore, ebm-papst selected textile ducts for air transfer throughout the garage. The ducting is very light but durable, compact for easy transport, and can be easily adapted to the size and layout of the garage. Depending on the garage, the air may be transported over as far as 25 meters from the rear part of the garage to the desired area. To ensure strong air flow at the end of such long channels, there is an efficient, high-performance RadiPac EC centrifugal fan installed in the cooling unit.

Endurance test in Malaysia

Before using it during an official race, ebm-papst tested the garage cooling under demanding climatical conditions.

The garage cooling system passed its first live test at the Italian Grand Prix in early September 2014. “Everything worked as we’d hoped and the system achieved the desired cooling effect without difficulty,” says Jones. For the next step, Mercedes-AMG Petronas Motorsport used a pit lane garage at the Sepang International Circuit in Malaysia for three days in February. However, the system failed to achieve the desired results. “The ambient temperature in Malaysia was considerably higher than in Italy, so at first we weren’t able to generate a perceptibly cool air current in the desired areas.

That wasn’t because of the cooling system’s performance; the air transfer was the problem,” explains Jones. He had parts of the textile air duct system transported to Britain and tailored them to deliver considerably stronger air flow at the critical areas of the garage. ebm-papst also changed the orientation of the air outlets. “Instead of trying to cool the air throughout the entire front area, we designed diffusers to direct the cool air where the engineers work,” says Jones.

Using the modified components, his associates at ebm-papst in Malaysia performed the next test in a factory building with an improved and satisfactory result: the cooling system reduced the temperature at the critical areas by almost 12 degrees Celsius — from hot and sweaty to comfortable.

“The comfortable temperatures in the garage were a huge help and enabled the team to perform to the best of our ability.”

Paddy Lowe, Executive Director (Technical) at Mercedes-AMG Petronas Motorsport

The system survived its baptism of fire in practical use at the Malaysian Grand Prix in late March. “We were really looking forward to having the ebm-papst cooling system operational in our garage in Malaysia. During the race weekend, the pace of work is extremely hectic, and it can be a really tough challenge for the drivers, engineers and mechanics in the particularly high heat and humidity locations. It was a huge help to us that the temperature in the garage was comfortable, enabling the team to perform to the best of our ability.” emphasises Paddy Lowe. During the race weekend, the system brought the temperatures in the critical areas down by up to nine degrees Celsius.

Because it’s working with water the cooling unit does not take up much space and can be easily transported.

Now the Formula One team will use the garage cooling system at all race circuits in Asia where temperatures are high and where no air conditioning exists in the pit lane garages. Using its global network of subsidiaries, ebm-papst manages the storage and logistics between the races — an additional facet of the partnership with the team. Gareth Jones is pleased that he and his colleagues were able to improve working conditions considerably for the engineers at the racetrack. “I always promised the team at Mercedes-AMG Petronas Motorsport: ‘We’re going to officially make you the coolest team in Formula One,’” he says with a laugh.

This is very complicated, good work from the engineers. Thank for sharing to us this article.

It is just like all the rest with Mercedes AMG Petronas : AWESOME