An office complex with a glass facade, a summer’s day with temperatures of 35 °C in the shade, full of people, maximum demand for ventilation and cooling and no maintenance or servicing due for a long time yet – that would be one way of describing the maximum requirements for an air handling system.

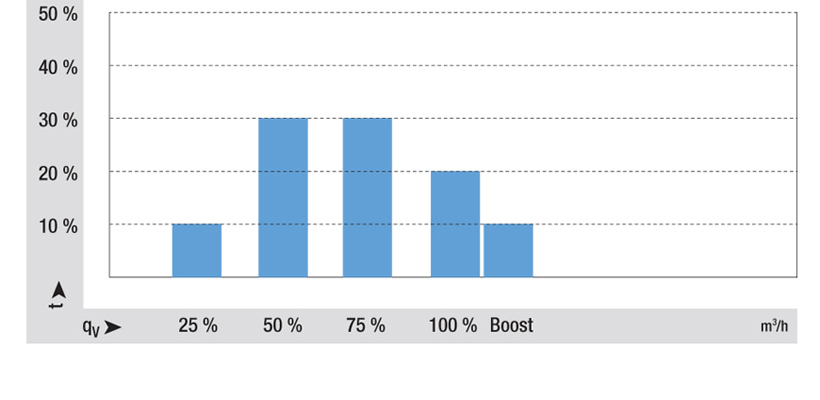

In commercial, municipal and industrial applications, maximum load situations only ever occur on a few days in the course of a working year (Fig. 1).

But the necessary cooling and heating performance and minimum air exchange rates still have to be reliably provided even then. The maximum load situation is thus the crucial factor for dimensioning of the air handling system and fans – but it is not the most important when viewed over the entire operating period!

Operating point and efficiency

An information brochure* issued by the German energy agency dena contains the following recommendation: “In the short term, the time of day, production fluctuations and weather conditions may cause the operating point to change.

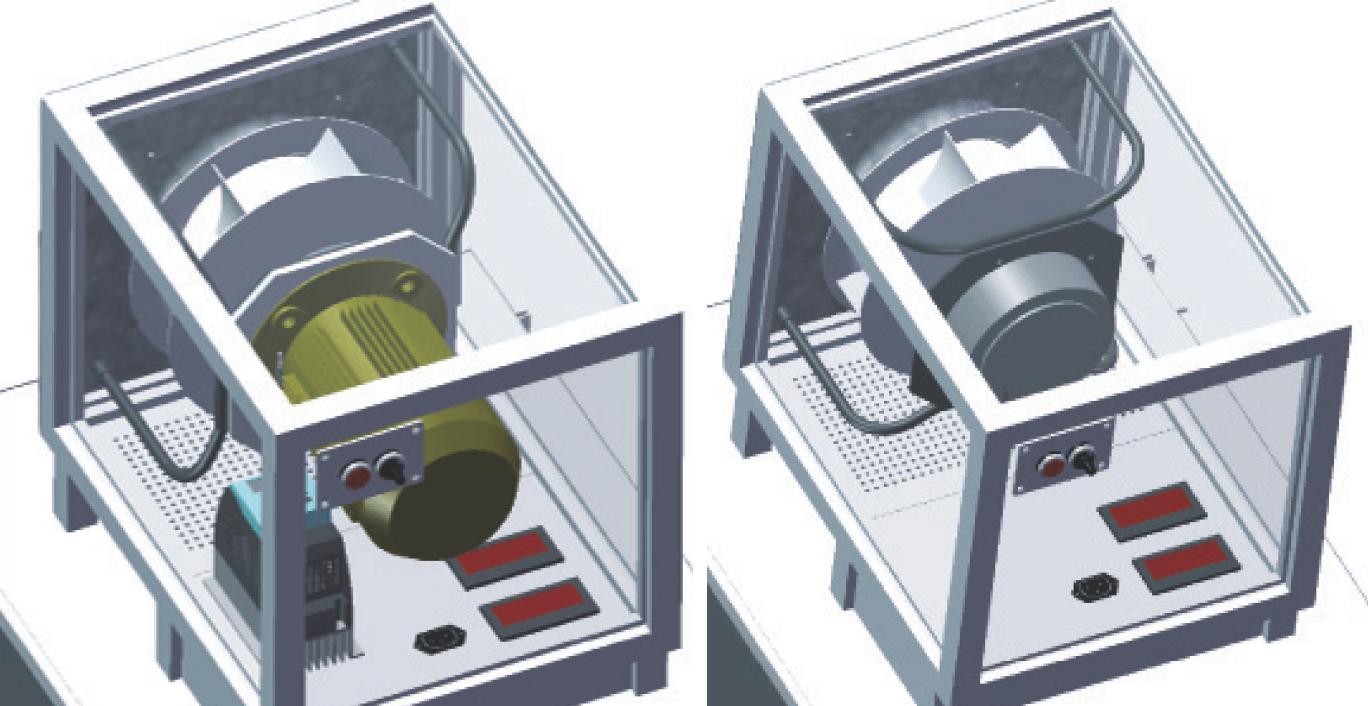

Fig. 3a, b, c: As compared to an AC standard motor with converter and the same power rating, the GreenTech EC motor is roughly 28 % more efficient for the load profile under consideration

Over the medium term, changes may come about due to seasonal influences or the degree of manufacturing capacity utilisation and in the long term as a result of increasing filter resistance etc.

Over the medium term, changes may come about due to seasonal influences or the degree of manufacturing capacity utilisation and in the long term as a result of increasing filter resistance etc.

Under such circumstances it would be wrong to set the design operating point (least favourable conditions and maximum performance requirement) at the point with the best efficiency level.

It is better to have the operating point for the most frequent operating situation set here. The ideal solution is to perform optimisation on the basis of the expected load and select the characteristic curve with the lowest annual energy costs.”

So the key is to have a technology which provides more or less infinitely variable adaptation of the air flow to the actual requirement. This ability is already integrated into the RadiPac for operation in air handling units. Its capacity for adjustment over a broad speed range ensures excellent efficiency and helps to cut operating costs. This is illustrated by comparing an AC fan with frequency converter to a GreenTech EC fan (Fig. 2).

For the load profile shown (Fig. 3a, b, c), the efficiency of the EC fan is around 28 % higher. In addition to reduced power consumption, other benefits include far lower assembly and installation costs, less weight and a space-saving design.

Correct values in partial load operation

Partial load is thus of considerable importance when planning and operating air handling systems with a view to keeping running costs to a minimum. RadiPac EC centrifugal fans provide an ideal solution.

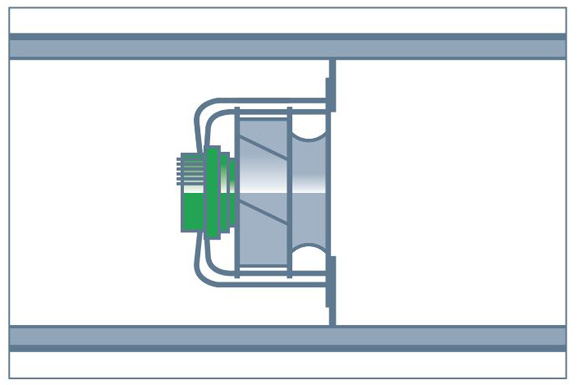

Fig. 2: System comparison between an IEC-E2 motor with frequency converter, sine filter and protective circuitry and a GreenTech EC motor from ebm-papst

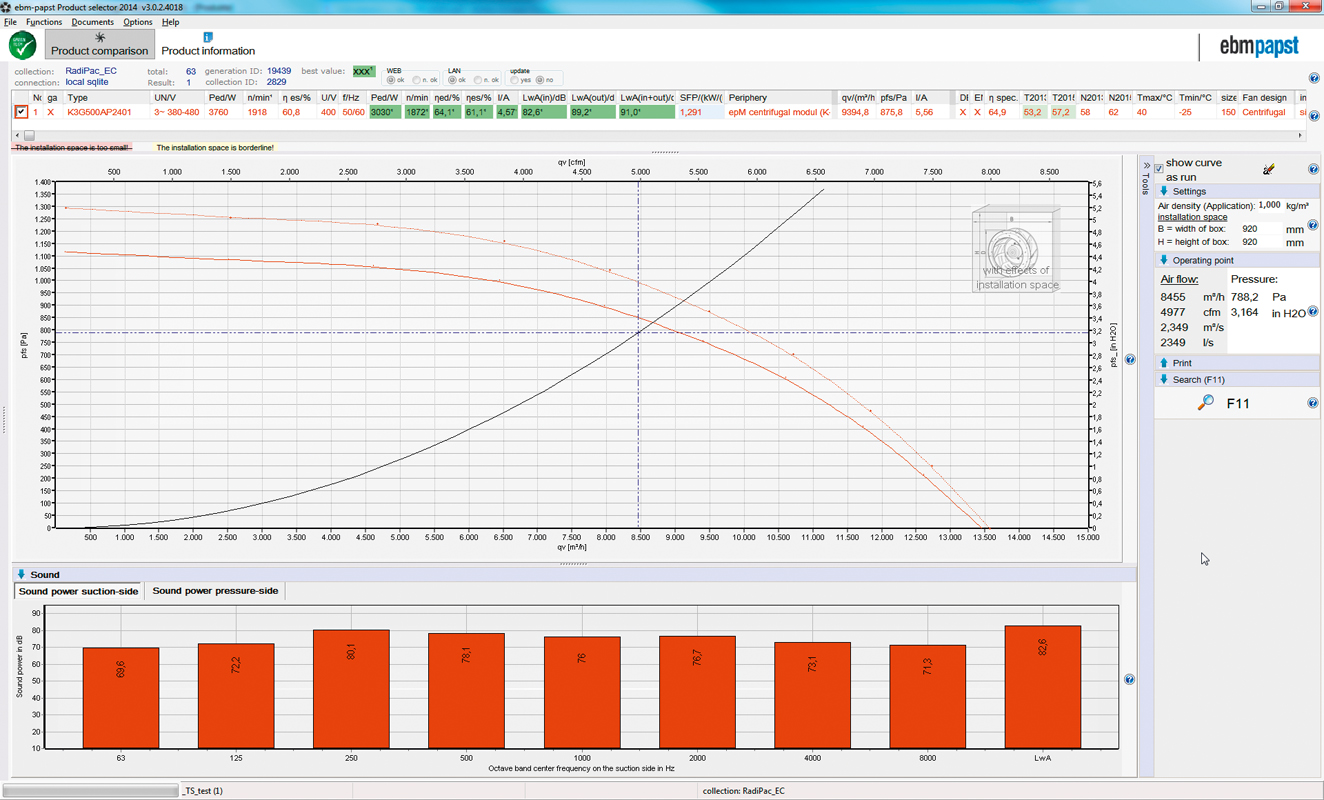

The certified Product Selector makes it possible to realistically simulate these operating conditions because its database contains the measured performance data of the fan. Absolute planning reliability is thus guaranteed.

Authentic operating conditions

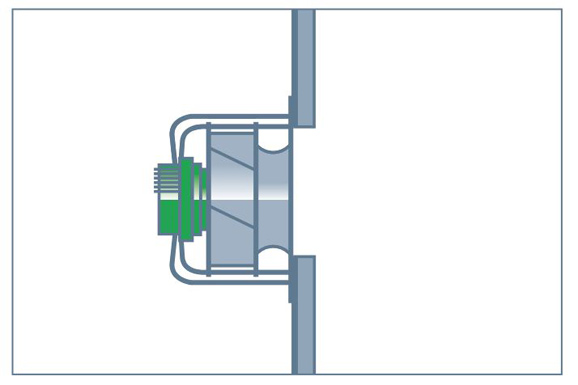

Category A measurements with free inlet and free outlet are definitive for the data given in the product catalogues and Product Selector and permit direct fan comparisons (Fig. 4a). The fans in an air handling unit operate in more or less confined spaces. This leads to a reduction in air performance which has to be taken into consideration when selecting the right fan (Fig. 4b).

ebm-papst’s documented values are based on customer requirements and the possible operating conditions involved. When choosing fans, the Product Selector makes it possible to incorporate various factors of influence, including the location of the air handling system or the available fan installation space.

Fig. 4c: In the Product Selector the “installation situation” can be represented by selecting the size of the air handling units

This permits a reliable assessment of energy efficiency, as well as operating and life cycle costs, because here again a whole range of correct values provide the foundation. The realistic consumption and performance figures supplied by ebm-papst help to ensure that the forecast performance values are actually achieved in practice (Fig. 4c). Selection of the correct fan is thus guaranteed.

*dena guide “Ventilation Technology for Industry and Commerce”

Leave a comment