Better air in classrooms and less expense for federal and municipal governments: Versatile ventilation systems from GLT Grohmann Lüftungstechnik make everyone happy.

Currently, the German federal government and cash-strapped municipalities are looking for ways to save money. Ideally, this should be done without cutting services or failing to comply with directives from Brussels. The German Energy Savings Ordinance and EU energy efficiency directive require energy-efficient upgrades of public buildings such as schools and kindergarten. These projects could be an example of how the public sector can save money and increase quality of life at the same time. After all, the German federal government spent some 650 million euro for heat energy in 2007. State-of-the-art, highly versatile air-conditioning and ventilation systems provide enormous savings here — while simultaneously improving room air quality. Grohmann Lüftungstechnik GmbH (GLT) of Forchtenberg, Germany offers practical fresh-air solutions with heat recovery that can be adapted to a wide variety of structural situations in a highly versatile manner.

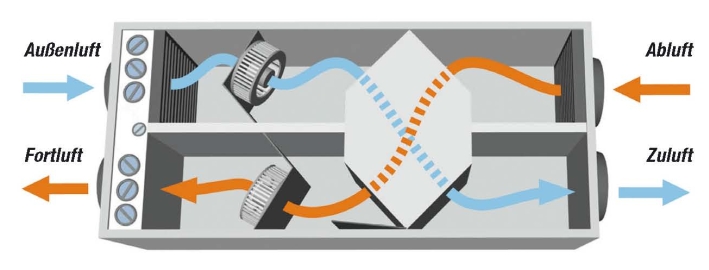

The SLG series school ventilation systems work in a demand-oriented manner, adapting to the requirements. The ventilation is matched to the current use of the room, depending on the number of occupants and how they are using it. This is ensured by an integrated CO2 sensor. If the system runs at the lowest setting, only the minimum base air exchange required for hygienic purposes is guaranteed. If the room air quality decreases, this signals an increasing CO2 value and the system increases the air volume automatically. The central unit guarantees excellent reuse of the exhaust waste heat, as it works with a heat recovery percentage of up to 90 percent.

If the outside air temperatures are very low, either an air mixture valve or an integrated hot-water heat register takes over the necessary heating of the fresh air. If the heat exchanger of the ventilation unit is located within the feed and return of a heating system, even more savings are possible: “The great advantage is that depending on the design of the classrooms, we do not have to use radiators in some instances,” emphasises Erwin Grohmann, the company’s owner. Moreover, the systems manufactured in Forchtenberg, Germany, guarantee that the children learn and play with clear heads, even if the outside air quality is relatively poor. Filter systems of various performance classes ensure healthy room climate even near heavily travelled streets.

The SLG school ventilation device from Grohmann with the two EC centrifugal fans and the heat exchanger

In the school ventilation systems, two EC centrifugal fans from ebm-papst Mulfingen provide the necessary intake and exhaust air flows — in energy-efficient operation. Even today, the fan motors exceed the requirements of the minimum efficiency classes that are planned to take effect in January 2011. They work with high efficiency of up to 90 percent and thus consume much less energy than the previously used AC motors at the same air performance. However, these potential energy savings are realised not only when operated under full load, but also primarily when operated under partial load. Where ventilation systems previously hummed so loudly that they made it difficult to concentrate in class, EC centrifugal fans eliminate this excuse for bad grades. they make no motor noise whatsoever, thus sparing the nerves of students and teachers alike.

Government coffers benefit from not only the energy savings, but also other advantages of these plug fans. The previously common belt drive between the motor and fan is omitted. The electronically commutated external rotor motor is integrated directly in the lightweight aluminium impeller, which drastically reduces the installation dimensions and the weight of the device.

This makes it substantially easier to fit the devices, already saving labour hours during installation. in addition, the system thus has fewer wear parts. For these reasons, and because of the materials used, the fans attain a service life of over 40,000 operating hours, which corresponds to running non-stop at maximum load and heat for four-and-a-half years.

However, school ventilation systems usually run in partial-load operation and at lower ambient temperatures. “Lower service costs means that government budgets save twice over the long term,” emphasises Grohmann. However, Grohmann failed to mention a great disadvantage of his system: In future, the children’s hope for a day off from school due to bad ventilation will be in vain.

Leave a comment