At ebm-papst, the focus of attention is on making top quality fans. Documented performance data and the correct choice of fan are only part of the story. It is also crucial to ensure that the fan is constructed in such a way that it actually attains the specified performance level in operation, regardless of the production date.

A certain amount of tolerance is inevitable with any technical product, for example on account of dimensional deviations in components and assemblies (e.g. enamelled wire diameters or electronic components). Tolerance limits can be set and action can be taken to ensure that these are not exceeded. This is the job of a company’s Quality Assurance department.

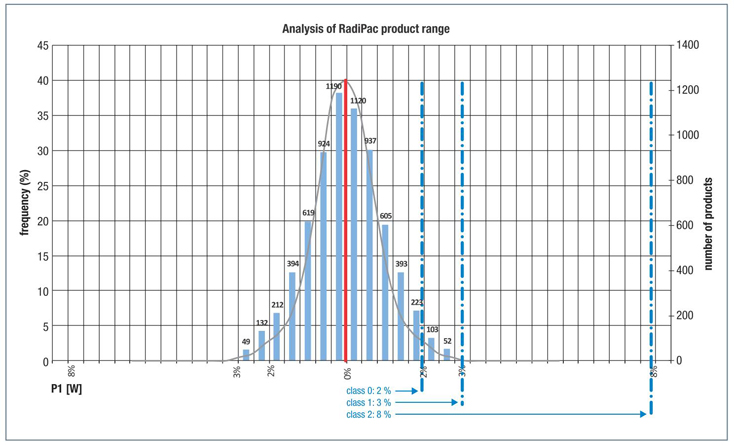

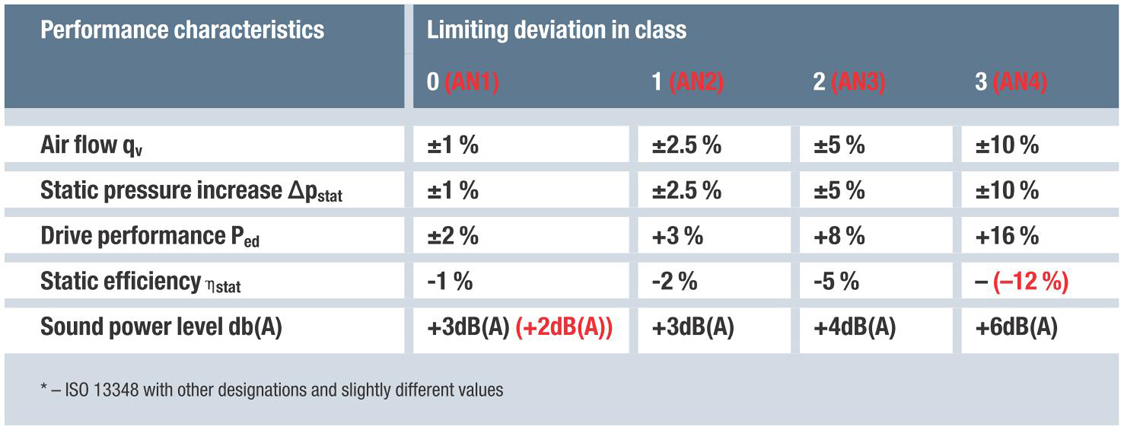

And the greater the possible deviations and the resultant performance deficits, the greater the safety allowance required when selecting fans. DIN 24166 – “Fans; Technical delivery conditions” therefore defines accuracy classes and permits deviations from the documented performance characteristics. The so-called limiting deviations are divided into Classes 0 to 3. The standard allows accuracy class 3 for fans smaller than 10 kW for example (Fig. 1).

Top class RadiPac

Fig. 2: The accuracy classes define production-related deviations from fan performance data. Accordingly the RadiPac product range attains Class 1. Analysis is based on performance measurements on 6,953 fans.

At the end of the production process, all RadiPac fans are checked in the as-delivered condition for any performance deviations. This quality assurance procedure involves recording all the electrical performance data and confirming compliance with the permissible manufacturing tolerances. Based on a size 500 RadiPac fan, analysis shows that ebm-papst attains accuracy class 1 (Fig. 2). For air handling unit manufacturers, this means that the figures given for the fan in the catalogue and Product Selector must not differ from the actual drive performance by more than 2 % and from the total efficiency by more than 1 %.

Planning reliability

Comparison of the product documentation and the actual product delivered reveals that in practice the power consumption of the fan will be lower and the total efficiency level higher than the documented figures. Consequently there is no risk of any unpleasant surprises when the air handling system goes into operation and there is also no need for any precautionary over-dimensioning of the fan.

Leave a comment