Attractive prices and individually customised design are the objectives of our development department. The prerequisites for this are flexibility and ever more advanced standards in the inside of our drives. This is underscored by the new motor laminations for our ECI module. In this article, I want to talk about some of the technical and cost-cutting highlights.

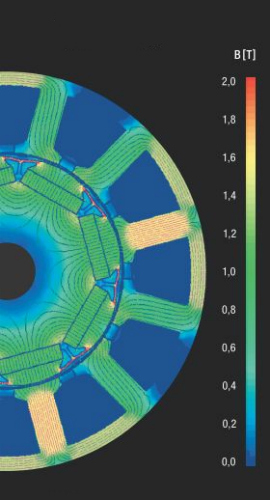

All common motor diameters, ECI 32, 42, 52, 63 and 80, are included in the new standard. In multiple iteration loops, we have optimised the magnetic circuit and the contour of the sheet steel so that a reduction of the detent torque by approximately 10 percent could be achieved. Simultaneously, this increased the power density by approximately 70 percent. With the ECI 6360, which has a motor size of 63 and an active motor length of 60 millimetres, a torque of 1 Newton-meter and an output of 420 watts is now attained. Basically, the length is flexible up to the maximum design; the preferred lengths are defined at 20, 40 and 60 millimetres. The end shields required for insulation can be used with the groove paper insulation for all lengths. The winding connections are defined with high precision, enabling a high degree of automation. To this is added the newly developed connection ring, which has a standardized configuration that permits all conceivable connections. In close collaboration between all members of the development team, we have designed the rotor and stator such that they can always be punched at the same time, thus avoiding waste of materials. For cost reasons, the magnets also have a cube-shaped design that is clever enough to allow the same magnets to be used for motor diameters ECI 32, 42 and 52; only their number differs according to the motor diameter. The connections and modules have been qualified in extensive tests and the series introduction has already taken place with the ECI 42 and ECI 63.

In summary, I can say that the technical improvements offer our customers solutions previously attainable only with larger drives and provide a cost benefit that applies even for smaller quantities, while also opening up new markets and applications. With the ECI module, we see great benefits for industrial drive engineering, intralogistics, medical technology or a wide variety of applications in this market. In addition, the benefits are evident in the automotive area for driving pumps, steering applications or adjustment requirements that impose stringent demands on the technical configuration while simultaneously meeting the price targets.

Leave a comment