Fans are needed wherever heat has to be dissipated. In close collaboration with Delta IDL, ebm-papst make sure that they are optimally employed. The engineering specialist based at Greifswald in North Germany is a specialist in simulating heat and air flow. since 2002, the experts have offered heat dissipation concepts and constructions for large and small customers, as well as its own self-developed products. What form the collaboration takes, and what chances and risks are inherent in heat and flow simulation, are explained by Delta IDL founder and managing director André Runge.

Can the benefits of simulation be expressed in figures?

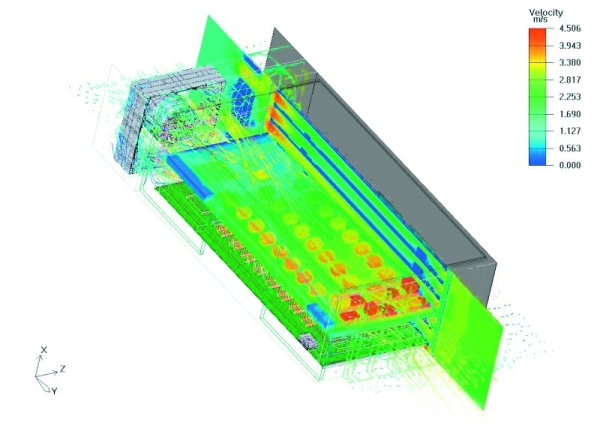

No. That would be difficult. The key advantage compared to measuring is that the cause and effect can be seen. For example, just because the acoustics and temperature are right when measuring, it does not necessarily mean that the optimum status has been achieved. Simulation allows a one-to-one depiction that shows the exact flow characteristics. In some cases, you can see that a piece of metal plate is all that is needed to screen off or redirect the flow – and the customer’s whole problem is resolved. But the difference is hard to express in figures unless you are conducting measurements and simulation in parallel. It all becomes clearer if you conduct virtual tests on different versions of a product, in other words once the simulation model has been defined. You can then enjoy an impressive benefit in terms of time.

Where are the limits of simulation?

We are able to offer such good simulation because we have the experience and because besides our own measurements, we employ measuring reports from the customer to verify our simulations. You cannot expect satisfactory results without experience in simulation tools. But you will always encounter applications in which practical experimentation is better than theoretical study, in which we also use measurements to support the simulation. This is done in particular when there are too many external factors that you cannot influence yourself or which you cannot precisely define.

So the major source of error in simulation is human?

Human and trust in the data used. The most important thing is communication. We often find that the “language” used within one project differs from one industry to the next. Sometimes it even differs within a single industry, technically speaking. We work with checklists, for example, to prevent any misunderstanding.

What precise form does the collaboration with ebm-papst take?

Starting with the concepts, we try to identify the appropriate fan. If we cannot find anything off the shelf, if we need measuring results, characteristics curves under particular pressure conditions or samples, we place a direct enquiry. ebm-papst researches quickly and without fuss. Together, we then define the optimum solution for the customer, enabling him to reduce, for example speed, and thus cost, energy and noise. It is a very close collaboration.

What moved you to use the fans yourself?

For our own products, we quickly decided to take this route because of something we have learned from the experience of our customers: They sometimes selected cheaper fans from the Far East, for reasons of cost. These rarely satisfy expectations with respect to noise, air performance or warranty. so at the end of the day they are not really cheaper at all. At ebm-papst we get the best products available on the market.

Leave a comment