In this article I want to take a look at the ErP Directive from the point of view of our customers, who are working to satisfy the requirements. The directive affects all sectors in which fans are used as the central component. Directive 2009/125/EC and its Regulation 327/2011 will dramatically change the design of many of our customers’ products.

Until now, manufacturers developed solutions that delivered the required performance on the one hand and were as cost-effective as possible on the other. For example, customers demanded that the special footprint for a machine be realised by designing a wall ring with a non-standard radius on the inlet side, or that it retains the same shape across a wide range of different products due to branding requirements, or that it allows only a limited height so that the machine could be more easily transported in a container. As a result, axial fans were combined with built-in nozzles for flat machines or the like.

When the first stage of efficiency targets went into effect in January 2013, equipment manufacturers and their fan suppliers were compelled to examine their product ranges to determine where a redesign of entire units becomes necessary. The reason for this is that the regulation treats the fan as a system (comprised of impeller, motor, housing and accessories such as a wall ring) needed in order to ensure a certain level of efficiency. This of course makes the fan strongly dependent on the conditions that determine its efficiency. Consequently, we as suppliers have to verify whether our components still fulfil the directives, but the customers are responsible for certifying the fan if they produce parts such as the wall ring themselves, because according to the directive, that makes them fan manufacturers.

The requirements in effect until the end of 2014 are not so difficult to fulfil, but that will change completely starting in January 2015 when the second stage of the directive takes effect and tough new requirements will have a big impact. A few percentage points of higher efficiency will be enough to cause many of the designs mentioned above to disappear from the market. That will most likely lead to a convergence in the designs of the offered solutions.

How will ebm-papst handle this?

With support from analysis to design, to find the best possible solution.

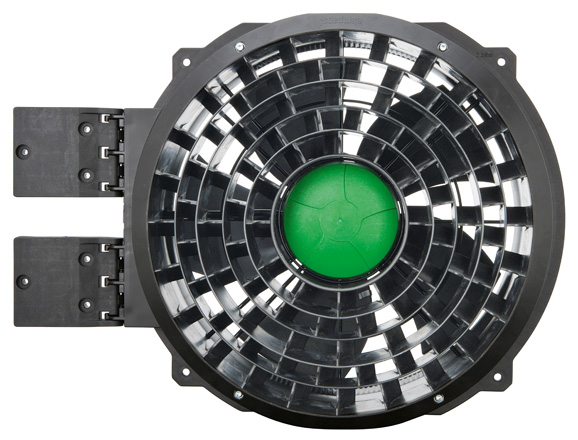

Where that’s not economical, a variety of standard products is available to help fulfil the efficiency requirements: With AxiCool, energy guzzlers can be brought up to ErP 2015 standards without expensive development and new tools. An example: The target for A4E350AP0601 is an η of 28.6 percent at the best efficiency point, well above the 25.9 percent reached by the current design. The W4E350JN0230 overcomes the Δ 2.7.

The conversion from AC to EC technology ensures that ErP 2015 requirements are fulfilled, and it pays off quickly thanks to the lower energy consumption.

Leave a comment