New tangential blower with low-voltage drive for building air-conditioning

Added up over the years, operating costs in buildings are a substantial cost factor and almost always higher than the initial investment. Many of the components used are in operation round the clock for years. As a result, even small improvements in the efficiency of the heating and cooling systems pay off quickly. If the purchase price of the improvement is cost-neutral to existing solutions, the savings start immediately. A new drive technology for tangential blowers in floor ducts combines two advantages: lower energy consumption with almost unchanged investment costs and expanded control options.

Targeted air conduction is important for an optimal room climate. In order to create the necessary prerequisites for this, the air is moved by smooth-running tangential blowers, especially in installations with floor ducts (underfloor heating and cooling systems). Kampmann, a company based in Lingen, Germany that specialises in building air-conditioning, has worked with this tried-and-tested system for years. However, to attain even better results in terms of energy efficiency and smooth running, the developers from Kampmann and ebm papst are using a new drive in state-of-the-art EC technology. This combines energy-saving operation with a long service life, easy installation and simple control.

Keeping total cost of ownership in view

The total costs over the service life of a ventilation system can be reduced significantly by the correct selection of a few components, such as fans. Therefore, the following primary criteria exist for the fans built into floor ducts: they must be cost-effective, maintenance-free, quiet in operation, save as much energy as possible and be easy to install. A tangential blower design fulfils exactly these requirements. The many blades of the fan roller enlarge the surface area that propels the air, enabling the rotation speed to be reduced and so allowing very quiet operation. The twin fan version circulates even greater volumes of air.In the past, these were often driven by shaded-pole motors as these are inexpensive at the time of purchase. However, a major drawback of this solution is its relatively low efficiency.

To keep noise levels low, it only works at 1400 rpm, but at this speed it is especially ineffective as a two-pole drive on a 50 Hz power line. That means firstly, increased power costs for the many fans needed in the building, and secondly, in the summer the cooling system also has to conduct the residual heat of the motor away, which requires even more energy. In order to be efficient and keep up with state-of-the-art technology, the air-conditioning experts at Kampmann are now employing the innovative drive concept from fan experts ebm-papst. The intelligent incorporation of EC technology in the new KaControl building automation system even allows the cost-neutral implementation in underfloor applications.

Outstandingly versatile EC drives

The electronically commutated direct current motor concept is ideal for meeting the requirement for high efficiency with a long service life and robust design. In this design, electronics integrated into the drive carry out the commutation instead of carbon brushes. It always governs the motor current optimally depending on the required power and speed. For this reason, efficiency remains uniformly high over a very wide speed and load range. This saves energy and minimises waste heat. The integrated electronics enable convenient control of the drive and reduce the need for external control technology drastically. The low-voltage drives require a mere 24 V DC as supply voltage, providing optimal reliability, especially in floor ducts.

Intelligent motor management ensures a constant speed, regardless of load, depending on control voltage. Moreover, it is possible to program special speed control “ramps” from the factory in dependence on the control voltage in the fan. This allows air circulation to be adjusted to the requirements of the installation directly in the fan, which simplifies the external control system.With internal rotor motors, the larger separation between the bearings improves the stability and smooth running of the rotating parts. Not even the “rough handling” encountered on the construction site has any major effect on the function or reliability of the fans.

Customised air flow

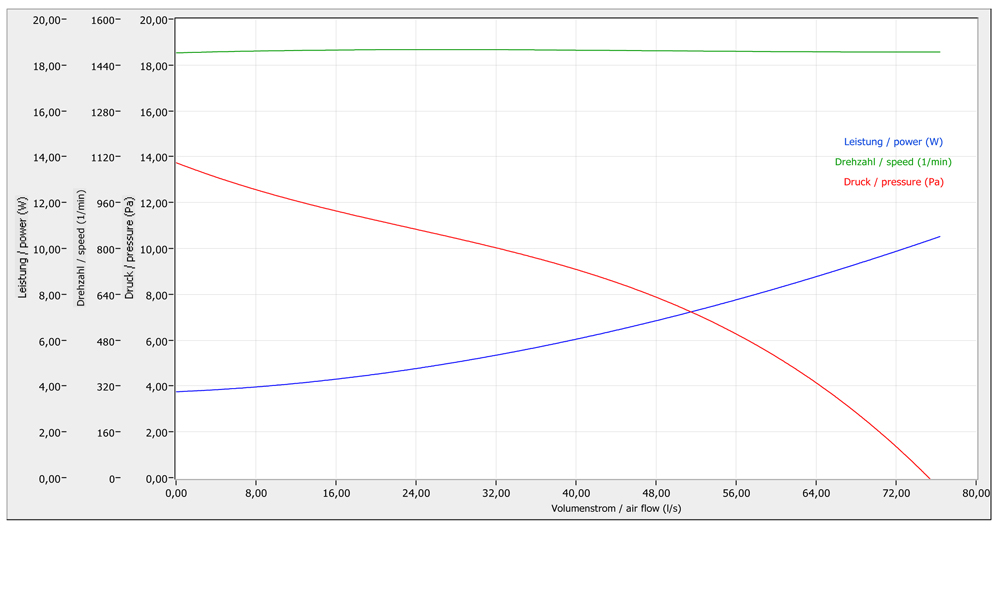

At present, there are two fan versions available. The QLK45/0030-2212 with an air outlet of 300 mm and the twin fan version QLK45/3030-2212 with 2x 300 mm air outlet. The total installation size is 395 x 79 x 70 mm (single fan) or 755 x 79 x 56 mm (twin fan). Both versions work with 24 (18…26.8) V DC and a control voltage of 0…10 V. An integrated Hall sensor (2 pulses per revolution) provides signals for the internal electronics, but these signals can also be picked up at the connector socket for external use. In the twin roller version, the fan displaces up to 72 l/s running at free air, with a maximum delivery pressure of 37 Pa. The power input in the characteristic diagram is just 6 to 10 W.

State-of-the-art drive engineering saves energy and installation time and thus real money, even in common current fan concepts for building air-conditioning. Inherent energy consumption is reduced by efficient motors, integrated electronics make installation easier and savings in control components are attained. Intelligent integration into the building automation system is the finishing touch that provides a clearly measurable increase in efficiency of the system compared to the conventional design, for the same investment. The installation engineer saves labour hours; the owner/operator saves energy and thus costs, with a greater degree of comfort.

The design of the EC drive

In the EC motor, the drive winding is housed in the motor jacket. The direct contact to the sheet jacket enables good heat dissipation. The low heat load, in turn, extends the service life of the motor bearings. The magnetic rotor consists of the gearbox output shaft and the rotor itself in the form of a permanent magnet with what is called the commutation track. Depending on the control solution used, speed (Hall) sensors provide the control electronics installed on the bearing shield with the necessary information about the position of the anchor. During this process, a simple control voltage between 0 and 10 V provides the electronics with the desired setpoint rpm. From the supply voltage, the control electronics generates a magnetic rotary field in the stator coils that depends on the speed and load. This always ensures the best possible efficiency at every speed.

Leave a comment