Quantum of the Seas is the queen of the ocean. The most expensive cruise ship in the world and a floating oasis for 4,180 passengers, it was launched in the summer of 2014. It is nearly 350 meters long and 41 meters wide. Entertainment features on board include a glass capsule on a swivel arm for panoramic views from a height of 90 meters, a climbing wall, bumper car rides, numerous restaurants, a musical stage, a surf simulator and much more. Taru Lähteenmäki, R&D manager at Koja, a Finnish supplier of air conditioning systems, says: “Vacationers here have high standards. For air conditioning too, of course. They expect the air to be at just the right temperature, no matter what climate zone the ship happens to be cruising through.”

Lots of power in a small space

Each cabin has its own air conditioning. Thus every passenger can set the temperature one prefers.

Each cabin has its own air conditioning, with which passengers can set the temperature they prefer. Together with the big EC blowers in the public rooms, 2,956 fans ensure a pleasant climate on board. Because of the salty and often tropically humid air at sea, the fans from ebm-papst have a special coating to protect them against corrosion. Many of the ship’s rooms are in the interior or have no windows that can be opened. Air exchange in most parts of the ship takes place only in the ventilation system.

Quantum of the Seas needed to consume 20 percent less electricity than its precursor ship. That was the requirement.”

Taru Lähteenmäki, R&D manager at Koja

Jukka Blåfield, technical manager at ebm-papst Finland, says: “A high rate of air exchange needs to take place in a limited space here.” One of the main challenges for air conditioning on ships is the available space. Lähteenmäki agrees, saying: “On a cruise ship, every cubic centimeter counts. All of the space needs to be available to the passengers or crew, so the electronics has to take up as little space as possible. For these reasons and others, we chose the compact but powerful ebm-papst centrifugal EC fans with forward-curved blades for the cabins, and RadiPac centrifugal EC fans with backward-curved blades for the public areas.”

Quiet energy-savers

When the cruise ship operator Royal Caribbean International ordered “Quantum of the Seas,” one of its most stringent requirements was: 20 percent less energy consumption than the precursor ship! That also applied for the air conditioning system. “The low energy consumption of the EC fans was an important reason for us to choose ebm-papst as our partner. The ship has over thousands of fans but only a few compressors, for example. If you want to achieve savings with air conditioning, the fans give you a huge amount of leverage,” Koja’s Lähteenmäki says. “Besides that, the fans are extremely quiet. So here too, they fulfill the high standards of the passengers.”

Relief for supply network

On a cruise ship, every cubic centimeter counts. So the on-board air conditioners have to be especially compact.

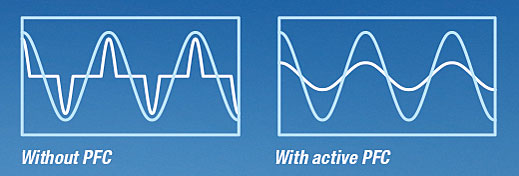

But when over 5,000 EC fans are connected to the same generator in the same network, so-called harmonics can lead to problems in the supply network. To avoid these problems, ebm-papst has developed a solution, a module that is integrated in the fan electronics: active PFC (power factor correction). The module filters out input current peaks with an electrical engineering trick that minimizes disturbing harmonic content. Jukka Blåfield summarizes: “Especially in the closed system on board, that’s a huge advantage. The active PFC technology allows the shipowning company to plan for a smaller generator from the start, since they can assume a lower peak load. That saves money, weight and space. And the power cables for the fans only need to be half as thick as without active PFC. That makes the system even more compact.”

Active PFC

The solution: ebm-papst has developed active PFC (power factor correction). A module integrated in the fan electronics converts the pulsed input current of the EC motors into a sinusoidal current. Then the current is shifted so that it is in phase with the voltage. This significantly reduces the harmonic content and minimizes the input current’s peak value. Electricity consumption remains at an acceptable value.

Leave a comment