If Rainer Müller were asked what his dream development project looks like, he would answer: “It would be great if we always knew from the beginning what we wanted at the end – and if nothing ever changed after that.” Müller says that with a laugh. As head of the Development Department for Product Section A1 at ebm-papst in Mulfingen, he knows that his wish will never come true, especially when a new product is involved. The Silvento ec from LUNOS is an example. Rainer Müller’s project team developed it in cooperation with its Berlin-based manufacturer. By using EC fans in these ventilators, LUNOS took a pioneering role and needed to approach the market cautiously. The features the new ventilators would need in order to stand out were clear. “High efficiency and low noise were the top priorities for us,” says Michael Merscher, technical director at LUNOS.

Constant change

Michael Merscher, technical director at LUNOS (Photo | Angelika Grossmann)

The two companies worked on the inline ventilators for bathroom and restroom applications for three years, an unusually long time for a development partnership.

The main challenge was that there were two parallel development processes for the Silvento ec ventilators. While ebm-papst worked on its fan, LUNOS tinkered with its end product. The effects every change had on the other components had to be taken into account.

“We didn’t have final control electronics until shortly before the start of production, and our fan also changed during the development process,” says Müller. “Of course that’s a challenge for both sides. The conditions can change suddenly because there are some things that can only be tested at a certain time.” So both sides had to be flexible – and willing to call the current status into question at any time.

Could be even quieter

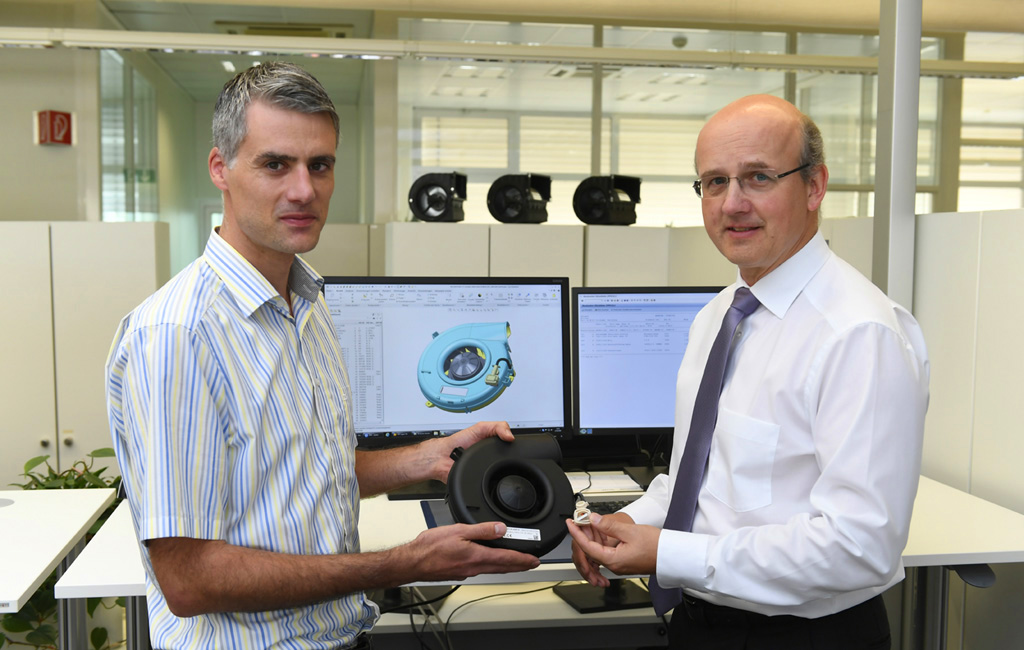

Müller and his team (Image above: project leader Johannes Ehrhardt and Rainer Müller) adopted different approaches during the project’s three-year duration. The original motor design fulfilled the efficiency and noise requirements specified at the beginning, but the project group still wasn’t really satisfied with the way the ventilators sounded. “So we dumped the initial design and started with another one,” recalls Müller.

Silvento ec – quiet and efficient:

- The Silvento ec has a power consumption ranging from 1.8 to 13.8 watts. For the previous version, the range was 5 to 35 watts.

- The lower power consumption means that the Silvento ec saves about 45 euros per year in continuous operation at 60 m³/h.

- Its noise level is up to 3 decibels lower, making it only about half as loud as its predecessor.

Until then, energy efficiency had played no role in bathroom and restroom ventilation. But both companies saw an opportunity to score points with end customers, and they made use of it. AC fans had been used for these applications previously. For the new ventilators, ebm-papst developed a new fan using EC technology. “But for easy replacement, it had to be compatible with the products that were already installed,” says Müller. The result is a logical refinement of the AC design, with the requirement to reduce noise and increase efficiency.

Combined expertise

“When we started the project, we established that we would bundle our core expertise. A quiet and efficient fan from ebm-papst combined with applications expertise from LUNOS,” says Müller. “We did that using an interface that Michael Merscher and his team based on the regulation technology they developed.” LUNOS changed the pressure-air flow curve with a regulation algorithm to keep the air flow constant in every conceivable installation scenario. “Without additional sensors, the ventilators can attain air flow constancy for wind loads up to more than 400 pascals,” says Merscher. “Both companies contribute their experience here: ebm-papst provides optimum control for the ventilators and LUNOS gives them the unique characteristics of its regulation technology.”

Shared trust

What nobody knew when the development partnership started is now clear: The effort was worth it. The Silvento ec ventilators have been well-received by the market and have even won prizes. They received the Plus X Award, an innovation prize for technology, sports and lifestyle products, as product of the year for 2016/2017. Looking back, Merscher and Müller agree that flexibility and mutual trust are the basis for success in a development partnership. “After all, both sides reveal things with a lot of innovative content at an early stage,” says Müller. “You really need a partner you can trust,” agrees Merscher. And an ongoing, in-depth exchange of information is indispensable for reacting quickly to possible changes. “Who knows at the beginning of such a project exactly what he’s actually going to need in two years?” says Müller with a wink. “We’re constantly refining the technology.”

Leave a comment