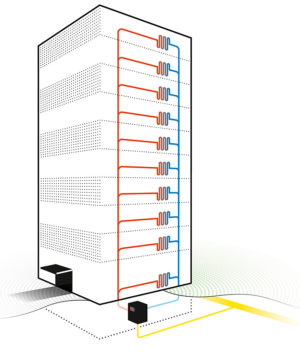

Figure 1: A conventional combined heat and power plant for district heating requires high investments in distribution grids with considerable heat losses over longer distances.

Until now, in many cases individual large combined heat and power plants have been used outside densely built-up areas to bring hot water to the consumer by district heating supply (Fig. 1). As energy prices and environmental standards increase, this method is not always the optimal solution in light of the heat losses, at least for new constructions. Instead, the trend is moving towards environmentally friendly, on-site gas heating systems. A decisive advantage is that the energy loss that necessarily occurs over long distances with district heating despite the insulation of the pipes, is a thing of the past.

The second advantage of this procedure is the savings in infrastructure. A simple gas pipe can handle a lot of energy compared to much larger district heating pipes with supply and return pipes. In addition, it is easy to see that an insulated pipeline is significantly more costly than a practically maintenance-free natural gas pipe for construction and later during operation with maintenance and repairs.

Trend towards local heating supply

Figure 2: Compact local on-site heating stations are an ecological solution for large buildings as well as for residential areas.

There are other factors in favor of the trend away from conventional district heating to local heating supply (Fig. 2). From an ecological standpoint, the material balance both in construction and in the operation of heating with natural gas is significantly better than in conventional district heating concepts. Especially carbon dioxide emission is relevant to the evaluation today. Natural gas is the fossil fuel with the smallest CO2 footprint and as such, it protects the climate.

Furthermore, the less additional pipes that have to be laid, the faster projects can be implemented. In the case of buildings like skyscrapers, on-site heating systems can save costs significantly and reduce the environmental impact. Even in the case of heat supply for residential areas, local heating supply can improve the environmental balance considerably. In addition, when new areas are being developed, the local distribution grid can be laid in the construction site quickly and on schedule without having to show too much consideration for existing infrastructure.

Variable output improves the operating balance sheet

Today, approximately 2 MW capacity is required to supply heating water and tap water to buildings with 50 stories or developments with approximately 100 single-family dwellings. Modern gas firing in premix technology is desirable because of its homogeneous mixture preparation at lower combustion temperatures and complete fuel utilization. Only very small quantities of unburned hydrocarbons or nitrogen oxides are emitted. In addition, a variable heat supply based on a modulating burner operation also increases the efficiency of the entire system. Therefore, precisely in boom cities with strong growth, a modern local heating supply based on natural gas is a genuine alternative to district heating in terms of the environmental footprint, economic viability, and fast construction progress.

Reducing the cost of installation

Figure 3: The new G3G 315 premix blower by ebm-papst Landshut offers a thermal output that can be modulated between 250 and 2,000 kW.

But until now, there has been one disadvantage: If larger thermal loads above 1 MW were required for single boilers, there were no suitable, highly efficient gas blowers on the market capable of being modulated over a wide range. In order to achieve these capacities, several boilers had to be installed on site to be operated in cascade. Besides the additional cost of installation, this also meant increased maintenance costs. With the new G3G 315 premix blower by ebm-papst, a broadly modulating gas blower that can be used for heating capacities up to 2 MW is now available to supply heat to larger units (Fig. 3).

Of course, 2 MW boilers equipped with this blower can also be operated in cascade for even greater thermal loads. This allows the local heating supply of significantly larger high-rise complexes, such as those that are being built with increasing frequency, especially in the Asian region (Fig. 4). Thus, the investments and ongoing operating costs of heat supply by natural gas are reduced considerably.

Good improved and adapted

Figure 4: For large buildings, a local heating supply on site (e.g. in the basement of a high-rise) can save costs significantly and reduce the environmental impact.

The new gas blower builds upon the many years of experience of the blower specialists. It is suited for gas condensing units and can also be used in other areas that require a lot of air, such as filtration or process air technology. In the development of this product, the specialists were able to rely on proved and tested motor components from their portfolio of blowers and adapt them to the special requirements of larger heat loads. This allowed the aerodynamics of the impeller to be matched optimally to the characteristics of the motor.

A new motor/electronics configuration now allows rotational speeds up to 6,000 rpm. Together, the efficient impeller and the optimized air duct design of the fan produce a broad turn down ratio of up to 1:8 for the blower. So the blower, as the first in its class, covers an input range from 250 to 2,000 kW in one unit. That is adequate to keep up with even strongly fluctuating heating requirements economically. Additional gas blower burners are under development for even greater heating capacities and will soon push the power limit of modulating gas premix boilers even higher.

Figure 5: The G3G 315 requires up to 4,300 m³/h (in open-jet operation) and builds up a maximum back pressure of 6,200 Pa (at full throttling).

In addition to the efficiency of the burning, easy integration in modern control systems was also a development objective. Thus, a standardized interface in the motor controller allows the transmission of all important data via a PWM or 0-10 V signal or Modbus RTU, for example. With 380 to 480 VAC and 50/60 Hz three-phase current, the G3G 315 requires up to 4,300 m³/h (in open-jet operation) and builds up a maximum back pressure of 6,200 Pa (at full throttling) (Fig. 5). Here, the flow medium temperature may be up to 50 °C and the maximum permissible motor ambient temperature is 60 °C. The power consumption of the GreenTech EC motor is up to 6 kW. The housing and fan impeller of the blower measuring 530 x 550 x 365 mm (L x W x D) are made of aluminum. A robust cover protects the motor and the electronics.

Leave a comment