For many applications, air is the ideal cooling medium to dissipate waste heat. For large amounts of heat in small spaces, a high-volume air flow is needed. Until now, high-performance fans that could deliver this air performance were loud, not especially economical to operate, and often could only be controlled in a limited fashion. A new generation of high-performance fans is now improving cooling efficiency and saving expensive energy. And for later disposal, the environment was already taken into consideration during the design phase, making it easier for users to fulfil both current and future standards.

As electronic components continue to get smaller and more powerful, they can be fitted into smaller devices with the same or even higher performance. This applies for many sectors such as IT, telecommunications and automation and also for frequency converters, welding machines and the continually improving solar inverters. The experts at ebm-papst have developed a new generation of high-performance fans, the S-Panther series (Figure 1), to give users of the latest technology a suitable fan solution. This generation was developed specifically with the aim of reducing noise emission, but without having to make compromises in air performance or efficiency.

New fan, proven technology

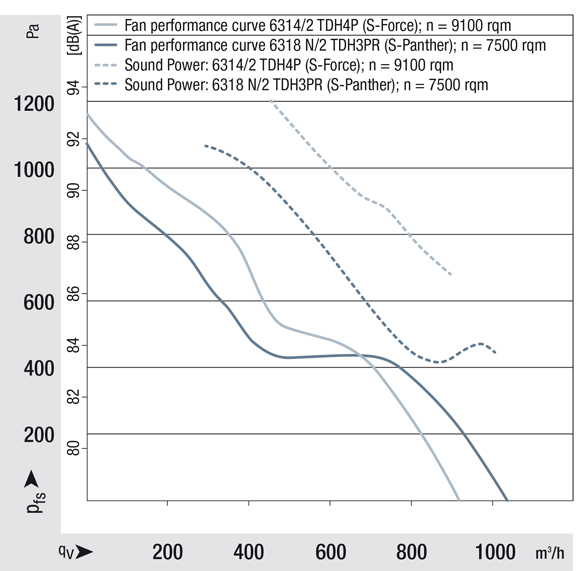

To achieve that aim, it was necessary to completely rethink the aerodynamics and develop the fan from scratch. A comparison of the performance data for the current 172 mm S-Force fan at 6000 rpm with that of the new fan from the S-Panther series with the same dimensions at 4500 rpm shows that the maximum air performance has increased and the pressure saddle curve has been lowered (Figure 2). This design is suitable for moving maximum amounts of cooling air for almost all applications. Thanks to a further design refinement based on blades with winglets and trailing edges, it was possible to reduce the sound power level across the entire frequency range. An additional contribution comes from a new strut design specially configured to the blade geometry. The improved air conduction allows reduced speed for the same air performance, resulting in reduced noise emissions.

When the speed of the new fan from the S-Panther series is varied so that the same curve as that of the previous model is reached, a considerable reduction in the sound power level can be observed (Figure 3). Even at medium power levels, the operating noise at the same operating point has been reduced by up to 9 dB(A). The operating range to the left of the indicated line is characterised by strong aerodynamic detachment mechanisms. The sound power levels of both fans are the same there. Nevertheless, here too the new fans feature crucial improvements as regards noise perception (Figure 4). So-called tonal noise in particular, which results from the number of blades and the speed and is always regarded as a nuisance, has been reduced considerably

The mechanical stresses on all fan components have been reduced by the new design and its accompanying speed reduction, allowing the use of new technologies such as the mechanical design of the plastic impeller, the shaft-hub assembly or the rotor dynamics.

The bearing systems can be kept simpler, and together with reduced effort for balancing, they facilitate production at the same quality level. Drive is provided by proven 3-phase multipole motors with 6-, 8-, 10- or 12-pole magnetised rotor units which together with the 9-slot stator packs efficiently convert electrical to mechanical energy.

Performance in figures

The sizes range from 80×80 mm up to 172 mm and cover all speed variants. Depending on the application, both low- and high-speed versions are available. Production of the new S-Panther fans will begin with the 63 and 32 series and will later be expanded to the 80 and 120 mm classes. All members of the new product family were designed from the beginning for environmentally friendly production and future disposal.

Hi,

We are a solar thermal expert company from Nepal. We are in the process of developing revolutionary modular solar air dryers from small to commercial scale together with our partner company in china who is already in the business of solar water heater manufacturing. We will require different fans for our air heater. We appreciate if you kindly email us the technical catalog of your S-Panther series fans (are they available in DC MPPT type?) enabling us to choose some samples to begin with. You may simply give us the link if the catalog is available for download.

Your prompt response will be highly appreciated.

Thanks and kind regards!

Dear Saroj,

Thanks for your comment which I have forwarded to our sales Team. They will get back to you.

Best regards, your mag°-Team