Compact fan dimensions are highly desirable for all ventilation and air conditioning applications. After all, installation space always tends to be at a premium. Energy efficiency is also an important aspect, not least because of the need to meet the minimum requirements set down by the Ecodesign regulation, which came into force for fans in 2015. Modern fans featuring energy-saving EC technology have plenty to offer in this respect: The compact fans do not just satisfy currently applicable and future requirements, they already clearly surpass them. This is of equal benefit to both the environment and customers, particularly as new concepts make retrofitting a simple matter for air conditioning unit manufacturers without the need for any design modifications.

Figure 2: The double-flow centrifugal fan product range in a scroll housing with backward-curved blades, shown here with mounting bracket in 90° position.

At present, the fans of ventilation and air conditioning units are often powered by asynchronous motors which drive the impeller by way of a belt. Such an arrangement takes up a lot of space inside the air conditioning device and makes installation complicated. The number of wearing parts also creates additional service work in the course of operation. What’s more, this widely used concept is not ideal in terms of hygiene, as belt abrasion can have a detrimental effect on the air quality. Another drawback to this constellation is that it is difficult to satisfy the demands for optimum utilisation of the primary energy supplied. In addition, the efficiency of asynchronous drives leaves something to be desired, with a level of between 20% and 70% depending on the shaft power. Speed control – for demand-based power adjustment or noise reduction for example – can only be implemented with the use of additional components such as frequency converters.

Direct-drive EC fans

Given these factors, direct-drive EC fans are an excellent alternative. EC motors exhibit the same characteristics as DC motors, can be just as easily regulated and attain efficiency levels of up to 90%. As well as making better use of the primary energy, another advantage is a reduction in heat loss during operation which has a positive effect on the service life of the ball bearings employed. A further argument in favour of using EC fans in ventilation and air conditioning devices is their compact external rotor design. The electronically commutated motor is integrated directly into the impeller, thus significantly reducing the installation dimensions (Figure 1). There is no need for a belt drive between motor and fan or a frequency converter. Thanks to EC technology, new air conditioning devices are more compact and so require less space at the installation location. It is however possible to put the energy-saving technology to good use in existing designs as well. Retrofitting, in other words replacing “old” with “energy-efficient”, is now no problem, as ebm-papst proves with the new RadiFit product range (Figure 2).

Energy-saving technology in the scroll housing

The double-flow centrifugal fan product range with backward-curved blades in the scroll housing was designed as an energy-saving system concept for any number of applications in industry and ventilation technology. Depending on the size, this is suitable for air performance levels of up to 10,000 m³/h (Figure 3). Thanks to the high-performance GreenTech EC drives, these centrifugal fans operate with a high degree of efficiency in combination with a high static pressure. The aerodynamically optimised blade channel of the high-performance impeller and the ideally adapted scroll housing play an important part in this respect. The overall effect is a reduction in energy consumption. Practical tests have proven that savings of more than 40% are possible as compared to a conventional cylindrical rotor AC fan with the same air performance. The fans are also extremely quiet-running thanks to the low-noise commutation and dynamic balancing of the impeller rotor unit. The generation of structure-borne noise is minimised, thus reducing the load on the bearings and so helping to extend the service life.

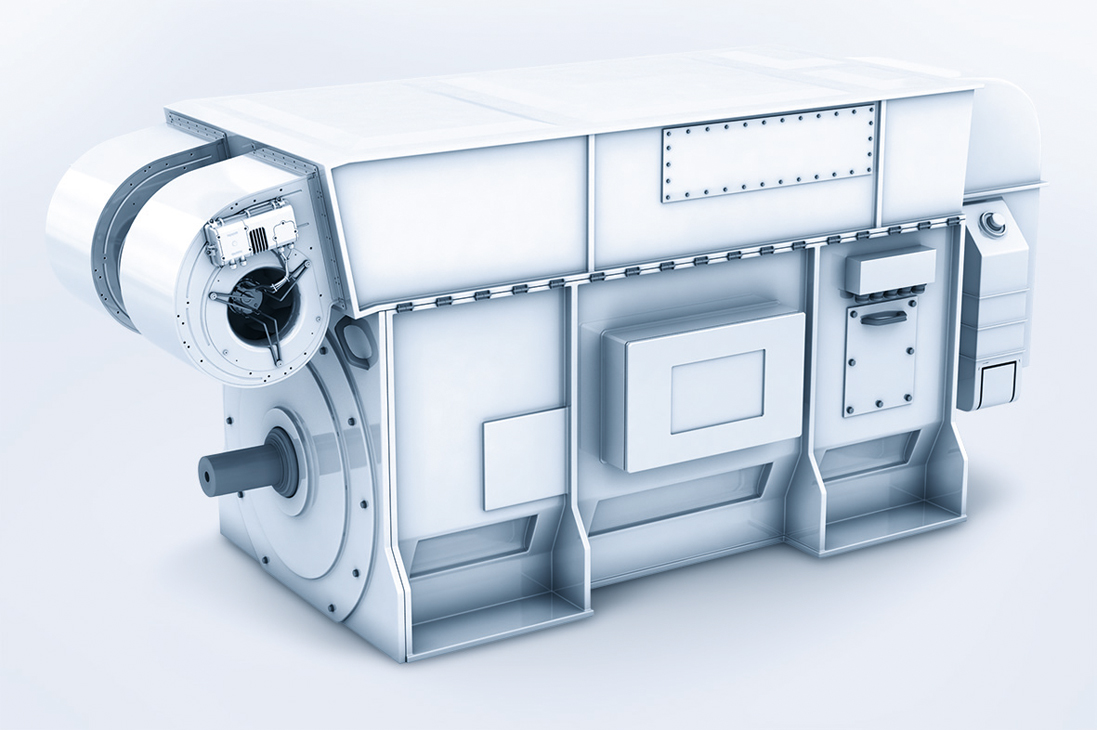

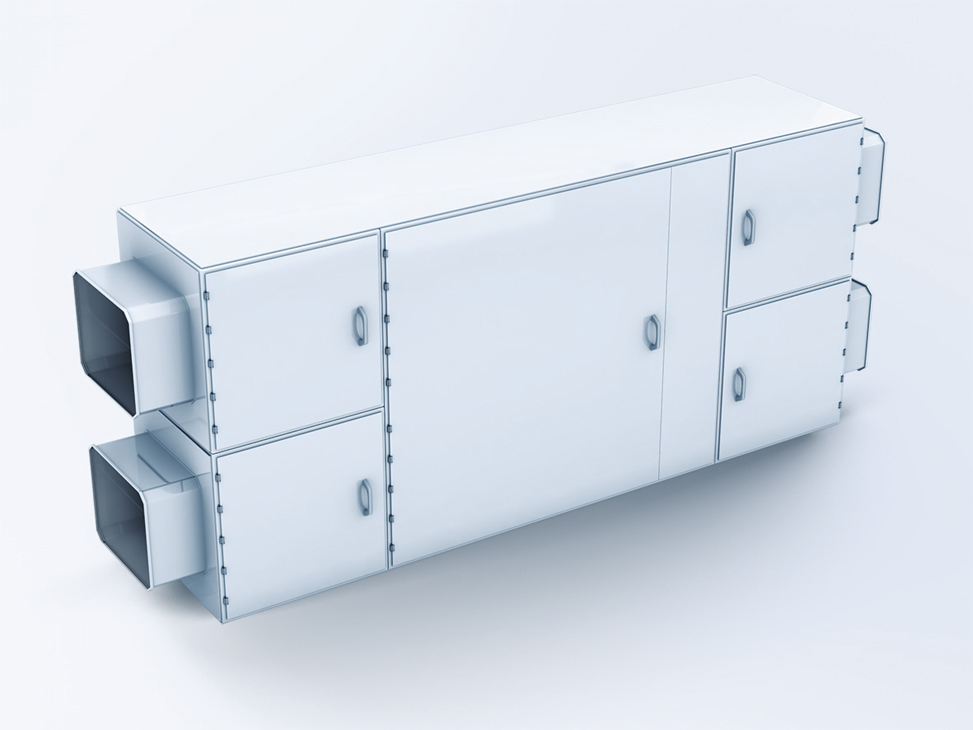

These characteristics offer advantages in a wide range of applications, for example in so-called low-profile air conditioning devices (Figure 4a) which use the heat of the exhaust air to warm the intake air. To do so, the fans convey the air through the heat exchanger and then through the intake and exhaust air ducts. Compact, energy-efficient EC fans with speed control are ideal for this purpose, particularly in view of the stringent energy conservation regulations applicable in this field. This similarly applies to central air handling units (Figure 4b), where the fans have to convey the air through filters, heat exchangers or humidifiers and dehumidifiers as well as branched duct systems whilst providing compensation for any loss of pressure. At the same time, the system must be as space-saving as possible and ensure simple, demand-based ventilation for a large number of rooms. Fans do however also have to satisfy similar requirements in industrial applications, for generator cooling for instance (Figure 4c). In this case the fan forces the ambient air through narrow ducts at the generator – which is where the new centrifugal fans really come into their own: Thanks to the integrated speed control, cooling can be constantly adapted to suit load and heat generation. And as it does not require separate actuation the fan needs little installation space.

These characteristics offer advantages in a wide range of applications, for example in so-called low-profile air conditioning devices (Figure 4a) which use the heat of the exhaust air to warm the intake air. To do so, the fans convey the air through the heat exchanger and then through the intake and exhaust air ducts. Compact, energy-efficient EC fans with speed control are ideal for this purpose, particularly in view of the stringent energy conservation regulations applicable in this field. This similarly applies to central air handling units (Figure 4b), where the fans have to convey the air through filters, heat exchangers or humidifiers and dehumidifiers as well as branched duct systems whilst providing compensation for any loss of pressure. At the same time, the system must be as space-saving as possible and ensure simple, demand-based ventilation for a large number of rooms. Fans do however also have to satisfy similar requirements in industrial applications, for generator cooling for instance (Figure 4c). In this case the fan forces the ambient air through narrow ducts at the generator – which is where the new centrifugal fans really come into their own: Thanks to the integrated speed control, cooling can be constantly adapted to suit load and heat generation. And as it does not require separate actuation the fan needs little installation space.

Modular concept with flexible connection options

Figure 5: The electronics with connection area can be fitted on the right or left of the housing; the user can then turn the connection area itself to the desired position or the cable exit can be fitted facing downwards.

EC centrifugal fans are designed for practical installation and can easily be adapted to different situations. Variable foot positions are possible for the size range 250 to 400 and the fans can also be supplied without a flange. Sizes 310, 355 and 400 are available in the successful cube design. The emphasis was also placed on flexibility with regard to electrical connection. For example the electronics with connection area (Figure 5) can be fitted on the right or left of the housing; the user can then turn the connection area itself to the desired position. The fans are supplied as a complete unit in a housing and wired ready for connection, thus providing customers with a practical Plug & Play package for their air conditioning applications. Being designed for different power supplies and operation in 50 Hz and 60 Hz systems, the fans are suitable for use throughout the world. With the RadiFit product range, an energy-efficient, practical retrofit concept for air conditioning devices is now available with immediate effect.

Leave a comment